Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

A technology of fluid production profile and testing method, which is applied in wellbore/well components, measurement, earthwork drilling and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

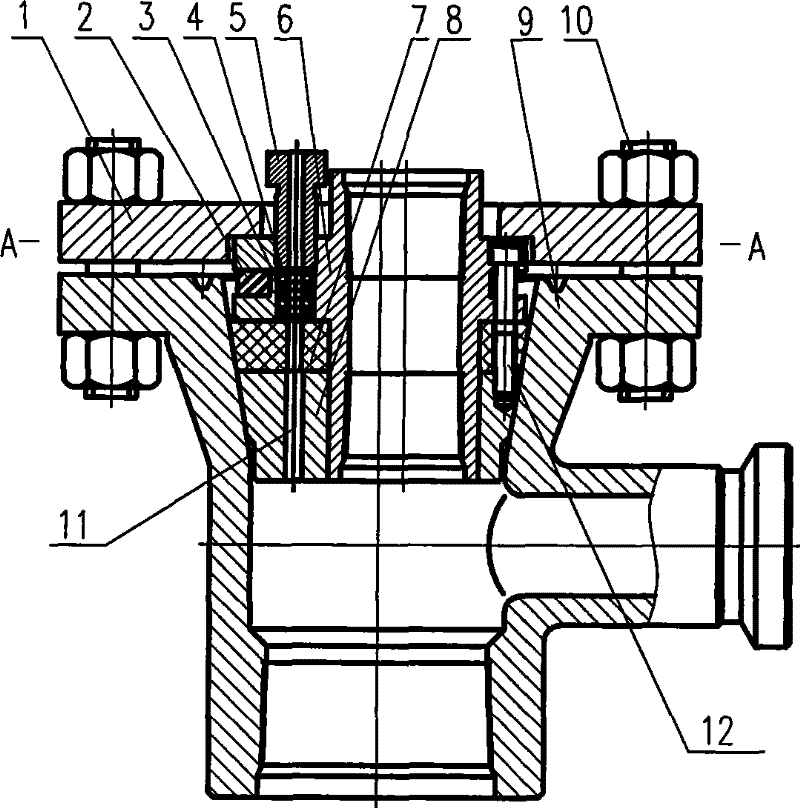

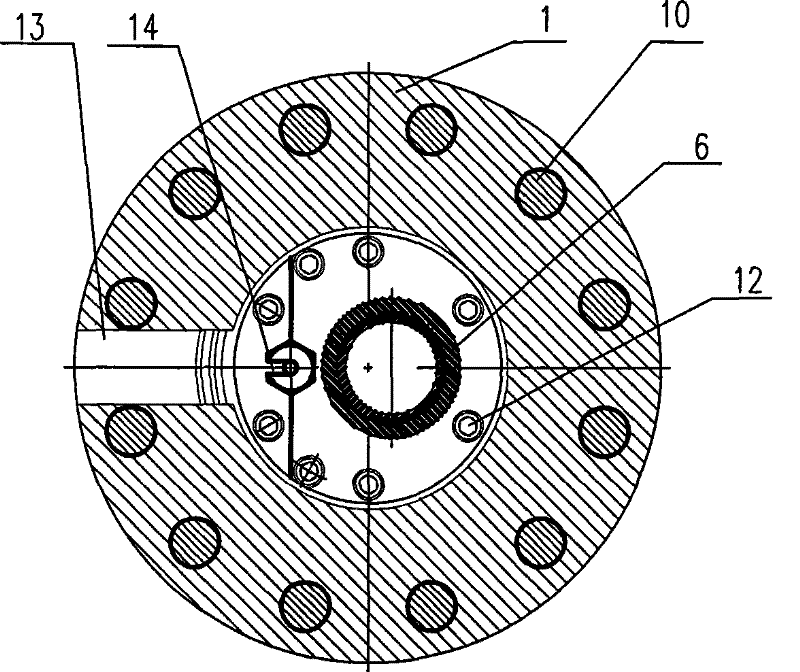

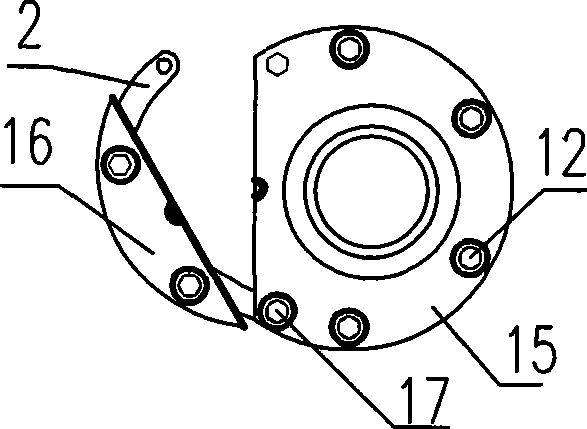

[0019] The method for testing the liquid production profile of the mechanically produced horizontal well is to use a special test wellhead device, pre-set the test instrument in the downhole, and cooperate with the downhole tractor to realize the test of the liquid production profile of the mechanically produced horizontal well.

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] attached by figure 1 , attached figure 2 and attached image 3 As shown, the special test wellhead device includes a special test wellhead and a wellhead support, and the special test wellhead includes a special flange 1, a large cross 9 and a built-in eccentric tubing hanger; There are side openings 13 for easy insertion and removal of test cables, such as figure 2 As shown, the radially evenly distributed bolts 10 are fastened on the flange of the large cross 9; the eccentric oil pipe hanger includes the eccentric oil pipe hanger mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com