Uses of bagasse in immobilization fibre bed reactor for fermentation production of organic acid as immobilization material

A technology of reactor and organic acid, applied in the application field of bagasse as an immobilization material, to achieve the effect of ensuring stability and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

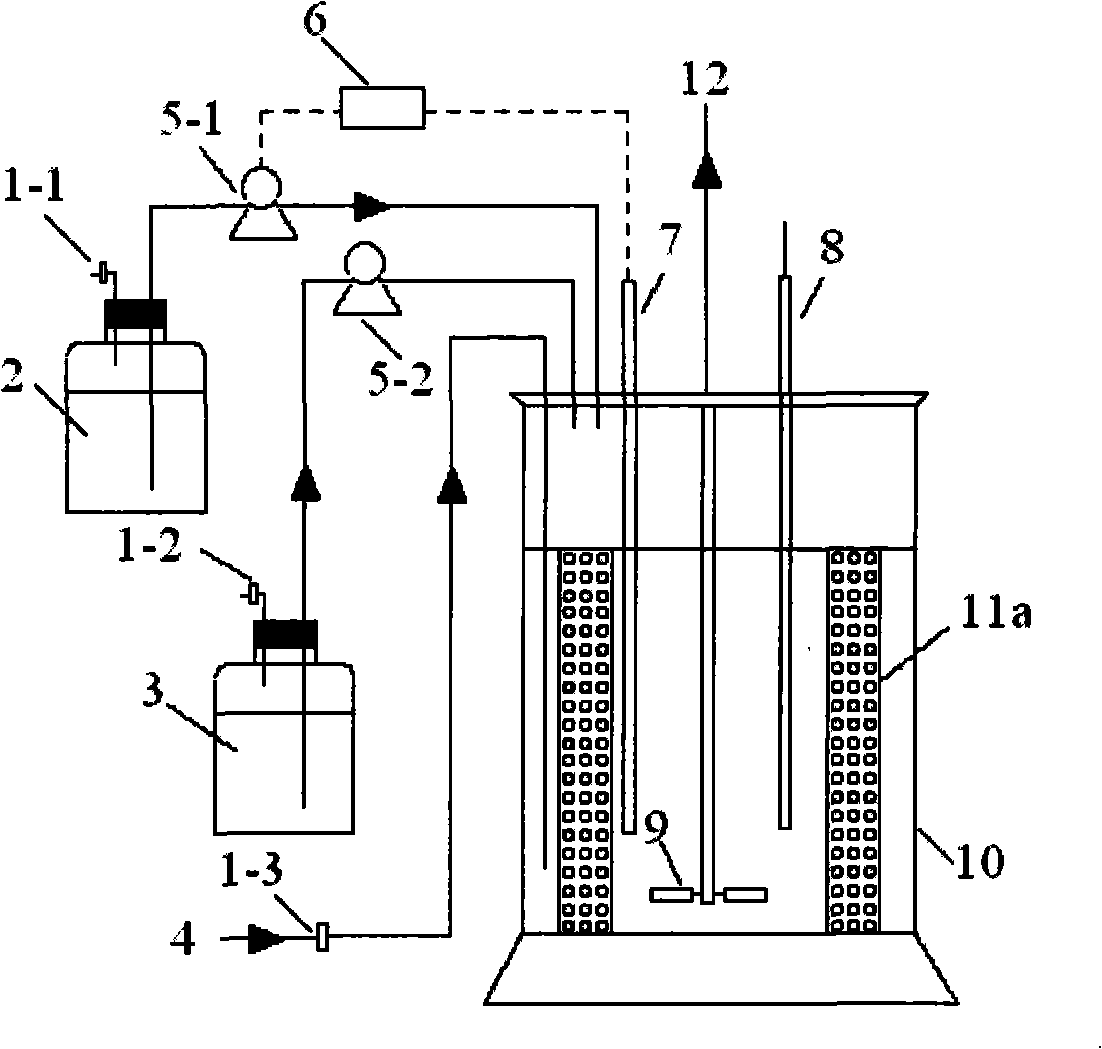

[0046] Embodiment 1 built-in plant fiber bed reactor produces propionic acid

[0047] Propionibacterium freudeenreichii NX-4 (Propionibacterium freudeenreichii NX-4, Chinese patent publication number: CN101182457A, strain preservation number: CCTCC No.M 207015), which has been patented by our laboratory, is produced in a built-in plant fiber bed reactor propionic acid. Seed medium: glucose 20g / L, peptone 5g / L, yeast extract 5g / L, NaCl 5g / L, pH6.9. Fermentation medium: peptone 10g / L, yeast extract 5g / L, NaCl 3g / L, (NH 4 ) 2 SO 4 5g / L, KH 2 PO 4 5g / L, pH6.9.

[0048] The bagasse was immobilized in the built-in immobilization column 11a, and the seed solution of P. freundii NX-4 was inserted into the seed medium pre-loaded with a volume of 3.6L according to the inoculum size (0.4L) of 10% (v / v). In the reactor 10 (total volume: 4L), the temperature is 35°C, and 0.1L / min N 2, utilize stirring device 9 to stir (rotating speed 100r / min), promote the constant exchange of int...

Embodiment 2

[0049] Embodiment 2 built-in cotton fiber bed reactor produces propionic acid (comparative example 1)

[0050] The bacterial species, culture conditions and feeding method are the same as those in Example 1, except that the immobilized material is changed from bagasse to cotton fiber. The built-in cotton fiber bed reactor was used to produce propionic acid. After 496 hours of fermentation, the output of propionic acid was 67.0g / L, and the production efficiency was 0.14g / L / h.

Embodiment 3

[0051] Embodiment 3 built-in plant fiber bed reactor produces propionic acid

[0052] Bacterial classification, culture condition are with embodiment 1. The initial glucose concentration is 100g / L, when the glucose concentration is lower than 10g / L, add 80g / L glucose again through the constant flow pump 5-2 (total glucose concentration: 180g / L), ferment for 350h, and the output of propionic acid is 74.3g / L, the production efficiency reaches 0.21g / L / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com