Single-component polyphenyl particle heat-insulating mortar

A technology of polystyrene particles and thermal insulation mortar, which is applied in the field of thermal insulation mortar, can solve problems such as confusion in construction regulations, safety concerns, and poor thermal insulation effect, and achieve the effects of eliminating waste, reducing white pollution, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further describe the present invention, a single-component polystyrene particle thermal insulation mortar of the present invention will be further described below in conjunction with examples.

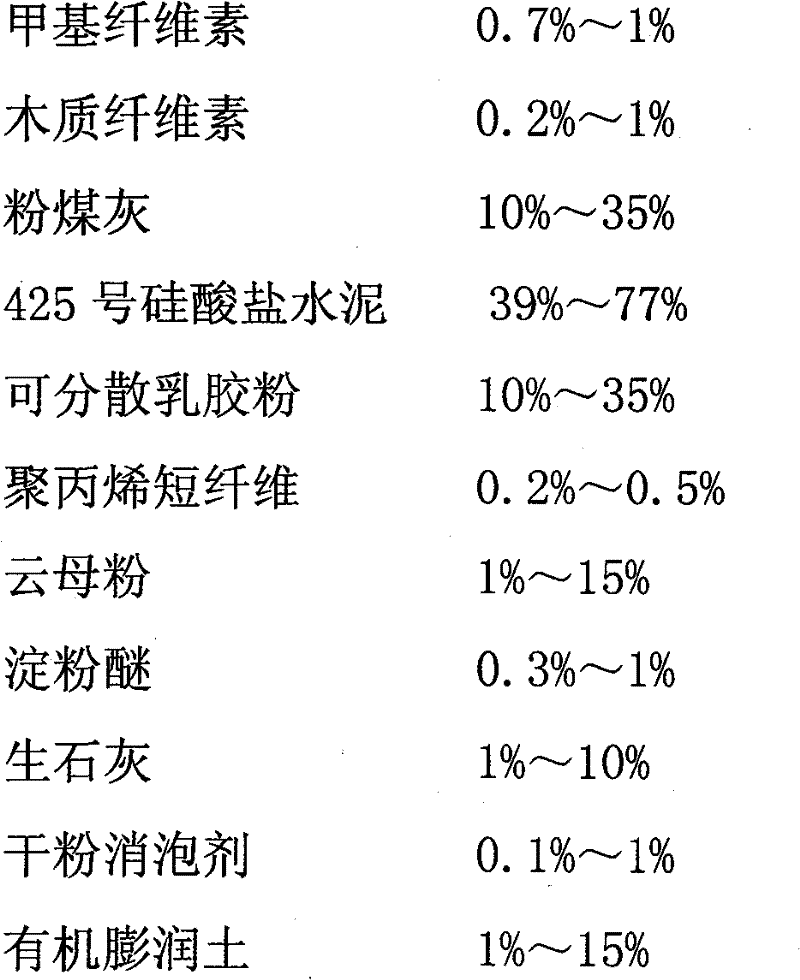

[0033] The embodiment formula of a kind of single-component polyphenylene particle insulation mortar of the present invention is shown in the following table:

[0034] Table 1 Example formula (% by weight) of single-component polystyrene particle insulation mortar

[0035] components Example 1 Example 2 Example 3 Example 4 Example 5 Methylcellulose 0.2 1 0.6 0.2 0.7 Lignocellulosic 1 0.2 0.6 0.2 0.5 fly ash 35 10 15 10 12 No. 425 Portland cement 39 55.6 48.23 77 45.0 Dispersible latex powder 10 20 35 10 13 polypropylene staple fiber 0.5 0.2 0.4 0.2 0.3 Mica powder 6.75 1 15 1 7 Starch ether 0.05 1 0.07 0.3 0.08 quicklime 6 10 1 1 6 Dry powder defoamer 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com