Totally-closed heat-insulation and energy-saving transmission equipment room

An energy-saving transmission and fully enclosed technology, which is applied in space heating and ventilation details, household heating, heating methods, etc., can solve the problems of high energy consumption of refrigeration equipment, corrosion of electrical components, etc., and achieve stable and reliable performance, low cost, The effect of job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

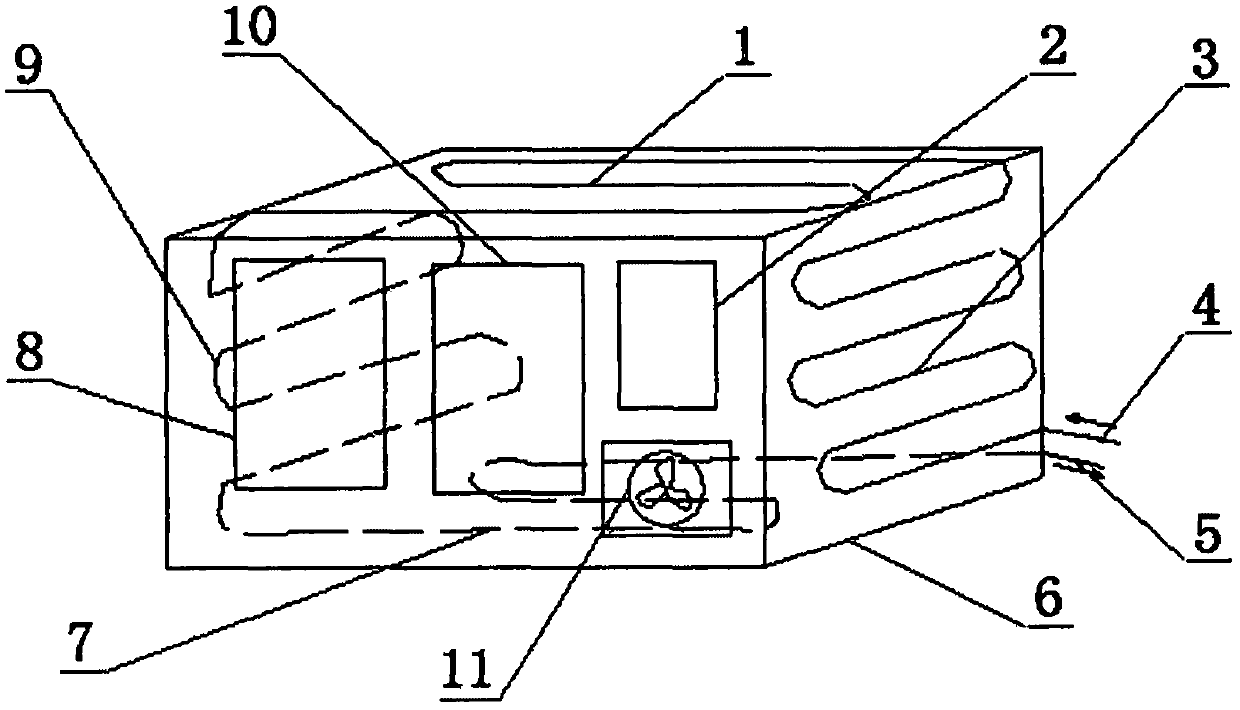

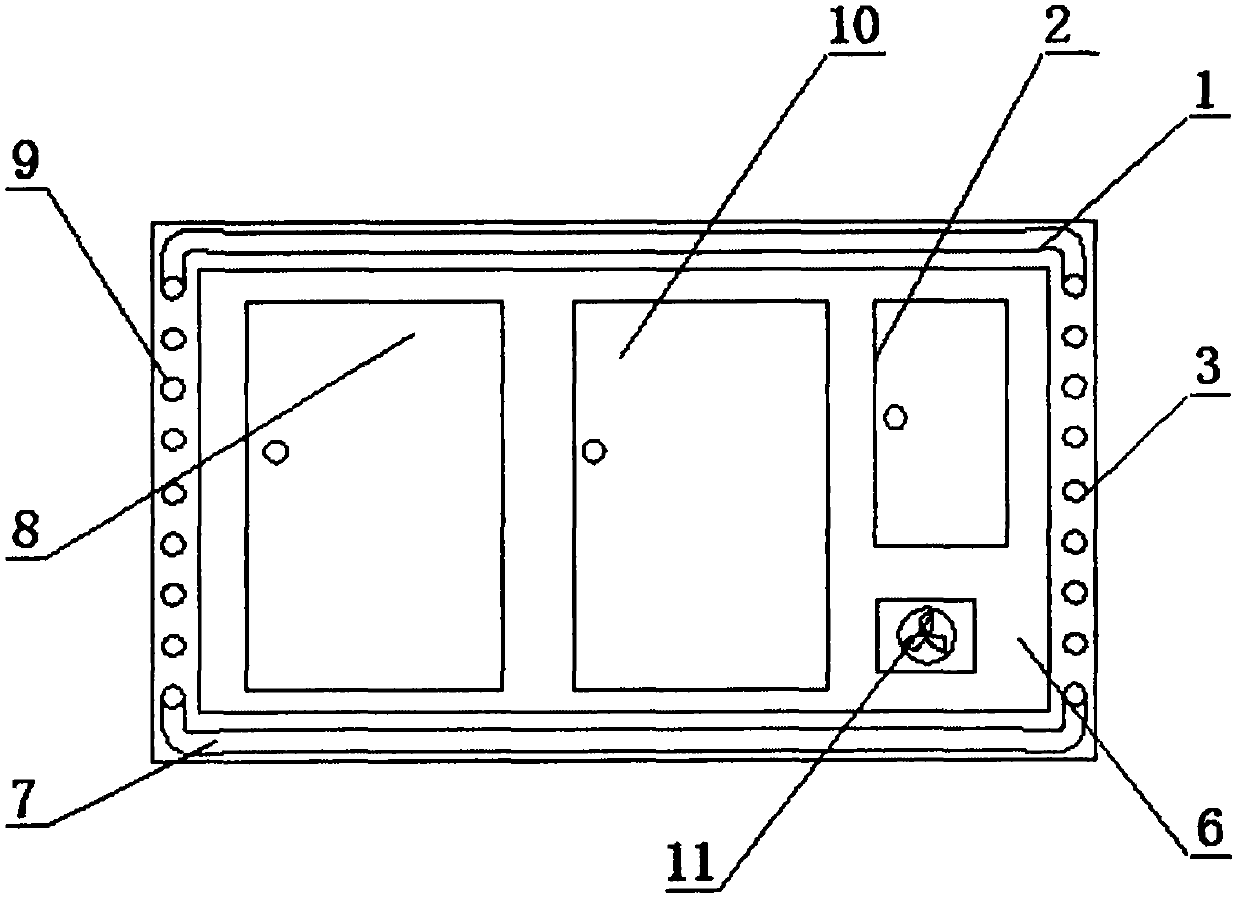

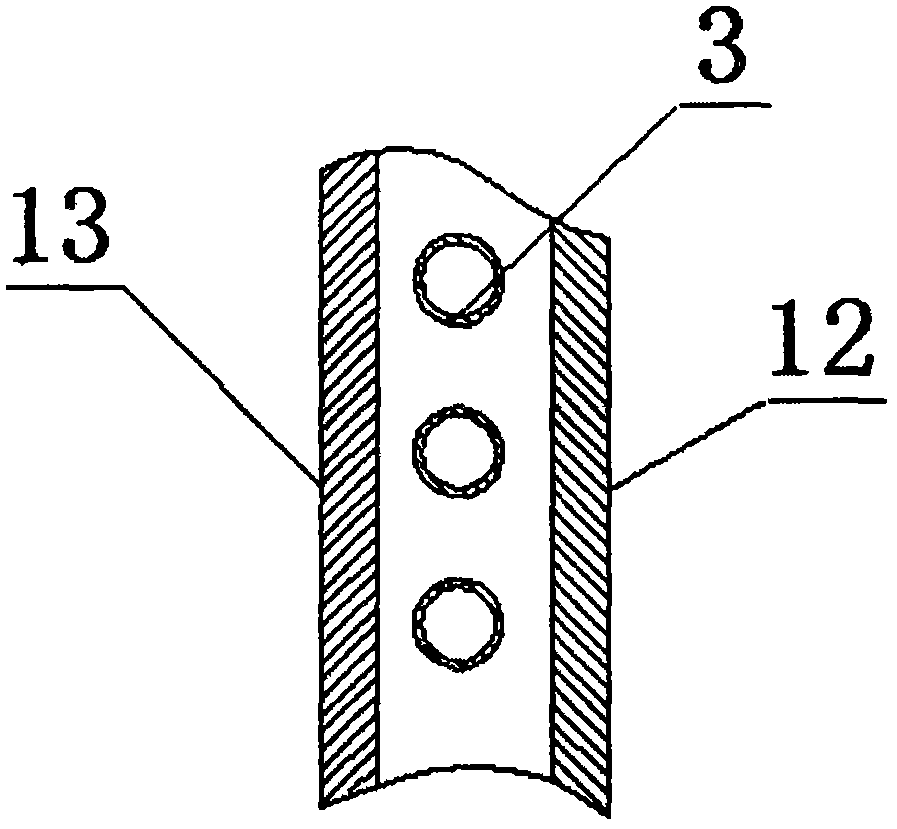

[0016] like figure 1 , figure 2 and image 3 As shown, a fully enclosed thermal insulation and energy-saving transmission machine room includes an entrance 4, an exit 5, and a cabinet body 6. The entrance 4 is connected to an S pipe B3, and one end of the S pipe B3 is connected to the entrance 4, and the S pipe B3 The other end of the S pipe A1 is connected with the S pipe A1, and the S pipe B3 is arranged in the right side wall of the cabinet body 6; one end of the S pipe A1 is connected with the S pipe B3, and the other end of the S pipe A1 is connected with the S pipe D9, S The pipe A1 is arranged in the top wall of the cabinet body 6; one end of the S pipe D9 communicates with the S pipe A1, the other end of the S pipe D9 communicates with the S pipe C7, and the S pipe D9 is arranged on the left side wall of the cabinet body 6 Inside; one end of the S pipe C7 communicates with the S pipe D9, the other end of the S pipe C7 communicates with the outlet 5, and the S pipe C...

Embodiment 2

[0020] like figure 1 , figure 2 and image 3 As shown, a fully enclosed thermal insulation and energy-saving transmission machine room includes an entrance 4, an exit 5, and a cabinet body 6. The entrance 4 is connected to an S pipe B3, and one end of the S pipe B3 is connected to the entrance 4, and the S pipe B3 The other end of the S pipe A1 is connected with the S pipe A1, and the S pipe B3 is arranged in the right side wall of the cabinet body 6; one end of the S pipe A1 is connected with the S pipe B3, and the other end of the S pipe A1 is connected with the S pipe D9, S The pipe A1 is arranged in the top wall of the cabinet body 6; one end of the S pipe D9 communicates with the S pipe A1, the other end of the S pipe D9 communicates with the S pipe C7, and the S pipe D9 is arranged on the left side wall of the cabinet body 6 Inside; one end of the S pipe C7 communicates with the S pipe D9, the other end of the S pipe C7 communicates with the outlet 5, and the S pipe C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com