Coating process and apparatus of coating machine

A coating process and coating device technology, applied in the field of coating machines, can solve the problems of wrinkles on the laser film, affecting the quality of the laser film, affecting the quality of the laser film, etc., so as to improve production efficiency and product quality, and reduce wrinkles. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

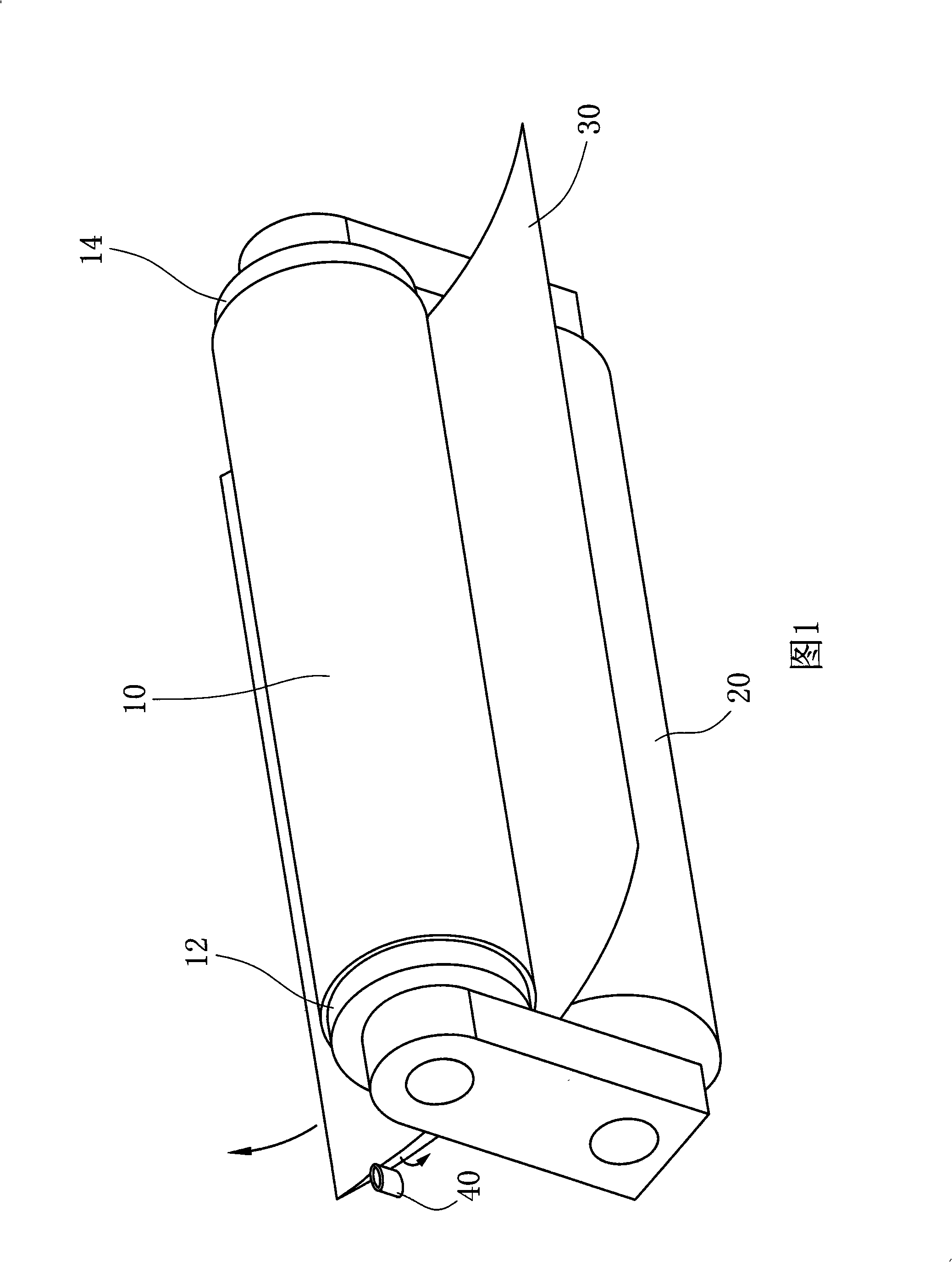

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0018] When coating the laser film, at least one of the two sides of the laser film along the moving direction is not coated with paint, so that the laser film has a thickness difference; when the roller squeezes the laser film, because the side of the laser film is thinner than the middle , so the pressure will be transmitted to the side, so that there will be no wrinkles in the middle part of the laser film.

[0019] In order to transmit pressure quickly, the two sides of the laser film along the transmission direction are not coated with paint, and after coating, the thickness of the two sides of the laser film is smaller than the thickness in the middle.

[0020] In order to prevent the coating on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com