Controllable pitch propeller unidirectional locking arrangement

A technology of one-way lock and controllable pitch propeller, which is applied in the directions of transportation and packaging, ship propulsion, and ship parts, etc. It can solve the problems of high pitch angle swing frequency of controllable pitch propeller, abnormal navigation performance of ships, and wear and tear of pitch control mechanism, etc. Achieve the effects of eliminating high pitch angle swing frequency, good running performance, and eliminating overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

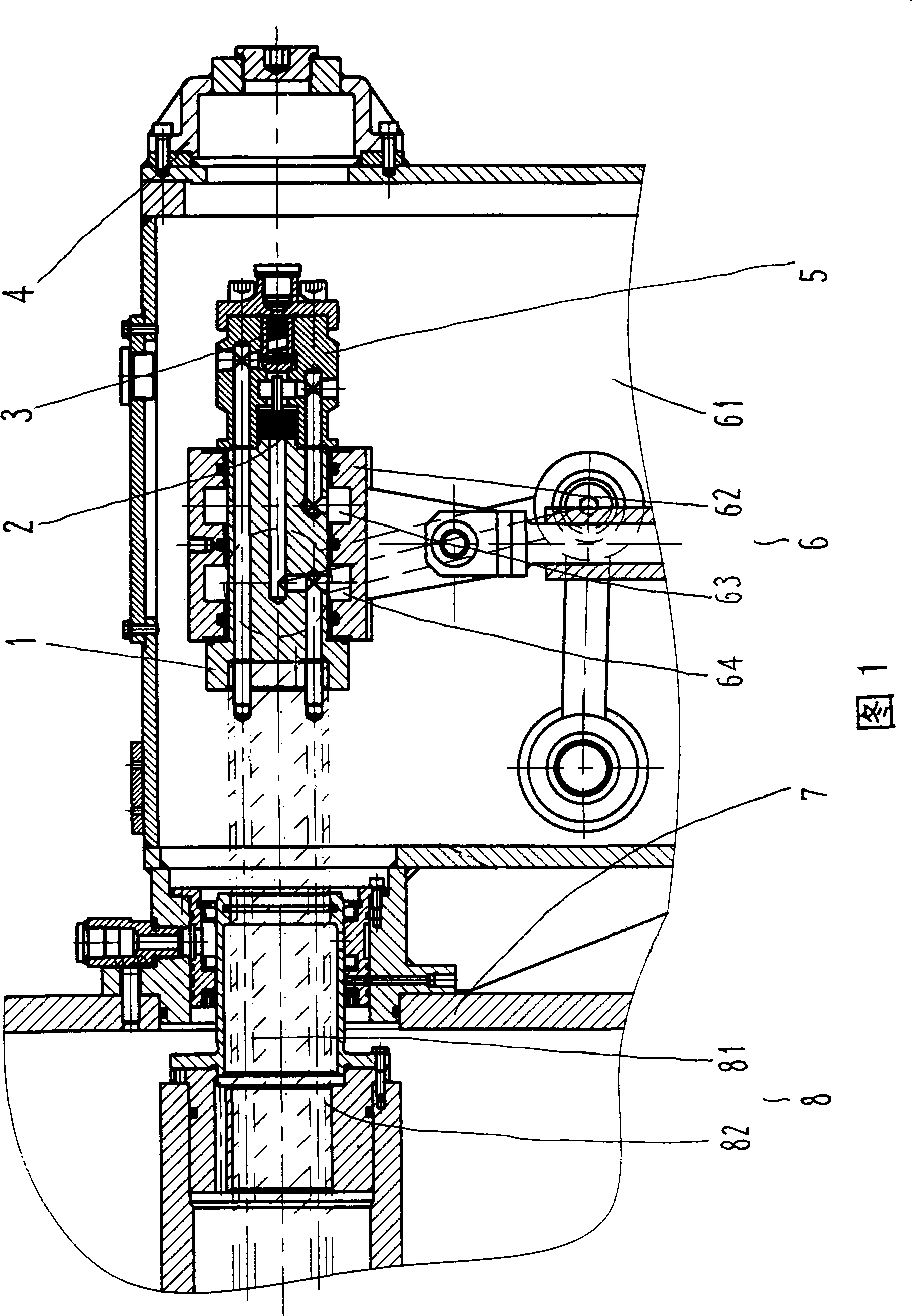

[0010] Referring to Fig. 1, the one-way locking device of the controllable pitch propeller includes oil distribution short column 1, control piston 2, one-way valve 3, gland 4, valve body 5, oil distributor 6, gear box 7, double oil hole pipe 8.

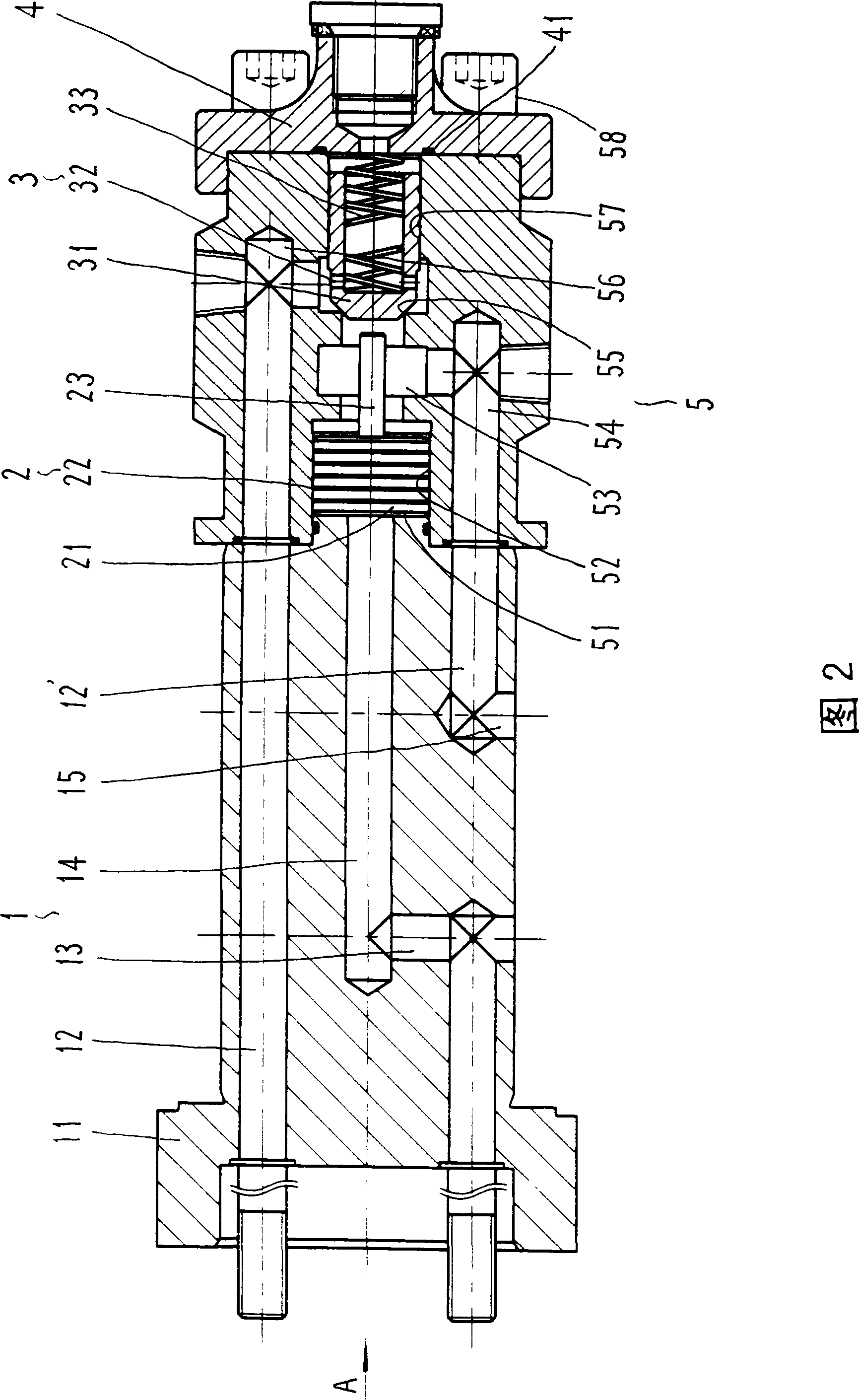

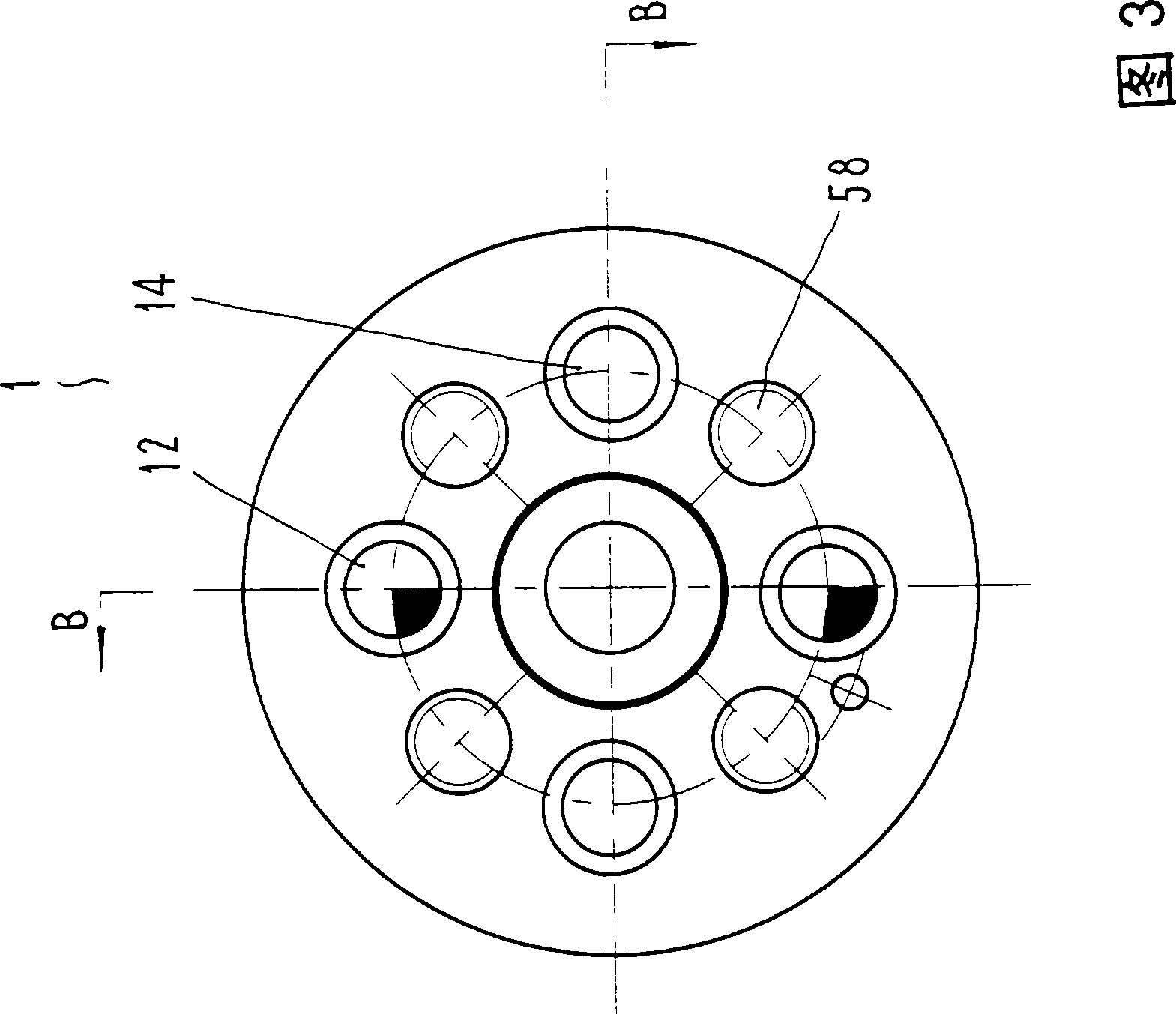

[0011] Oil distribution short column 1, as shown in Figure 2, its main structure and reversing distance adjustment oil circuit are the same or similar to the existing structure, the outer cylindrical surface and the sealing sleeve 62 of the oil distributor 6 are in a sliding fit, and keep it in a rotating state As shown in Figures 2 and 3, the short oil distribution column 1 includes a column body 11, a longitudinal hole 12 for the vehicle, a transverse hole 13 for the vehicle, a longitudinal hole 14 for the vehicle, a transverse hole 15 for the vehicle, and another longitudinal hole for the vehicle 12', wherein the oil circuit is a schematic cross-sectional view of B-B in Fig. 3:

[0012] The oil circuit of the front car part is: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com