High effective absorbent for separating acid gas

An acid gas and absorbent technology, applied in separation methods, through absorption, dispersed particle separation, etc., can solve the problems of reducing the efficiency of absorbent compounds, accelerating equipment corrosion, equipment corrosion, etc., to achieve energy reduction, equipment corrosion reduction, oxidation reduction, etc. and degradation stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

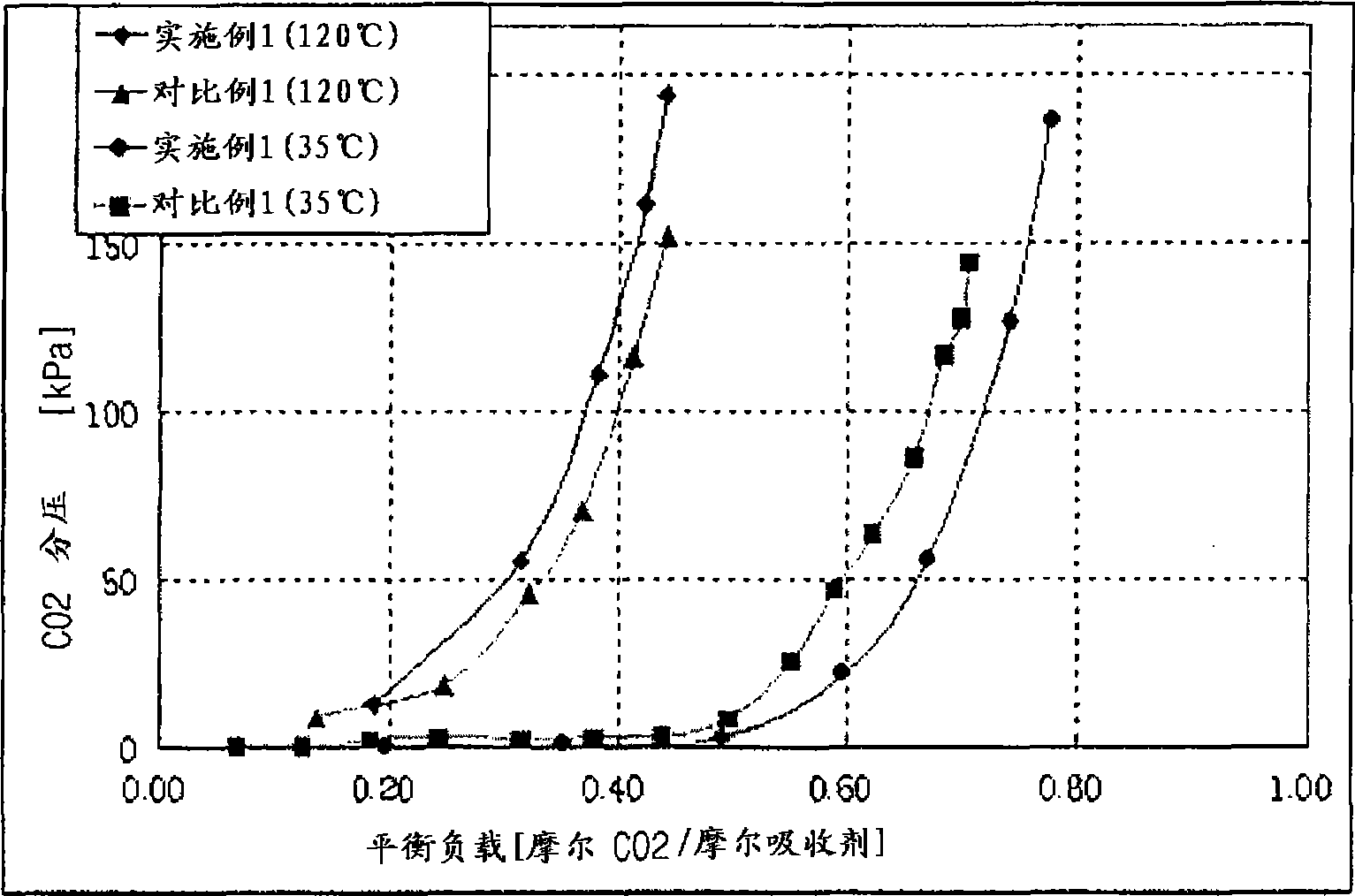

[0051] Put 100mL of 2.00M 1-amino-2-propanol:piperazine (9:1) mixed aqueous solution as an absorbent into a 700mL stainless steel pressure-resistant reactor equipped with a stirrer. Carbon dioxide gas was transferred from the carbon dioxide storage tank to the reactor, and the saturated absorption of carbon dioxide was measured at a carbon dioxide partial pressure ranging from 0.0 kPa to about 150-200 kPa. The reactor and carbon dioxide storage vessel were preheated to the desired temperature in an oven, and the gas-liquid equilibrium curves at 35°C and 120°C were measured, respectively. The result obtained from this is as figure 1 shown.

Embodiment 2

[0053] A glass reaction vessel was immersed in a water bath at 40° C., and then 300 mL of a 2.00 M mixed aqueous solution of 1-amino-2-propanol:piperazine (9:1 ) was charged. Under atmospheric pressure, a gas consisting of 15% carbon dioxide and 85% nitrogen was dispersed at a flow rate of 3.0 L / min through a glass tube and absorbed into the absorbent. The concentration of carbon dioxide in the gas at the outlet of the absorption solution is continuously measured in an infrared carbon dioxide analyzer, from which the absorption rate, absorption capacity and absorption load of carbon dioxide are calculated. At a given time point (approximately 90 minutes), when the absorbent is saturated with carbon dioxide, the reaction vessel is transferred to a water bath pre-warmed to 80°C, and the rate of removal of carbon dioxide from the absorbent is determined. Removal volume and removal rate for 30 minutes. The results thus obtained are given in Table 1 below.

Embodiment 3

[0055] In the same device as in Example 2, a 2.45M 1-amino-2-propanol:piperazine (100:1) mixed aqueous solution was used as an absorbent to measure the removal rate of carbon dioxide and CO in the exhaust gas. 2 Loading on absorbent. The results thus obtained are given in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com