Method for determining the surface quality of a support and machine for transforming the associated support

一种表面质量、加工机的技术,应用在确定基片的表面质量领域,能够解决效率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

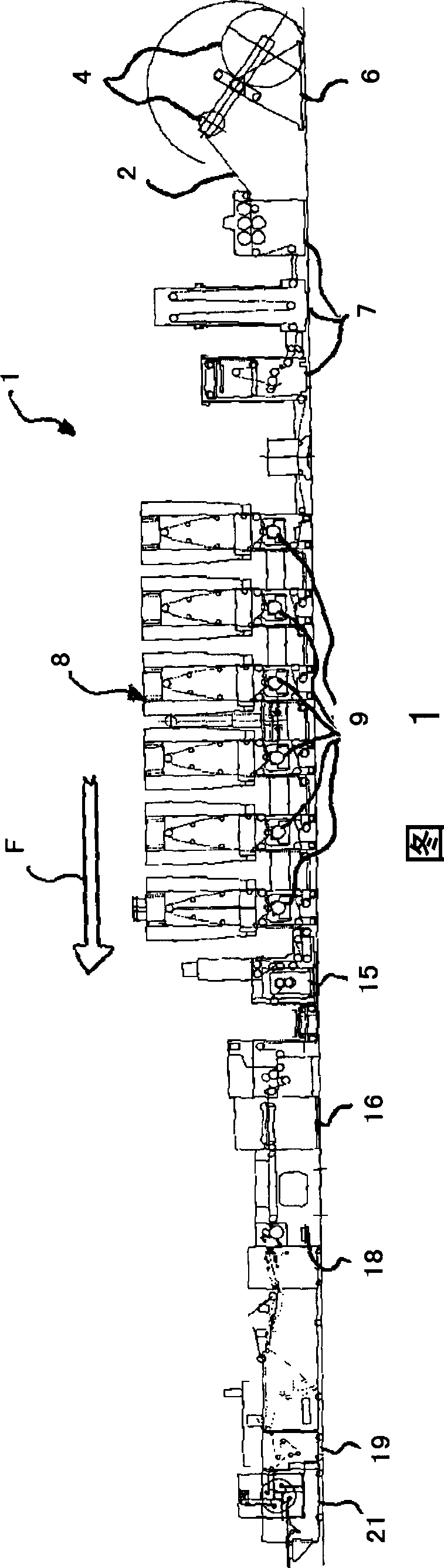

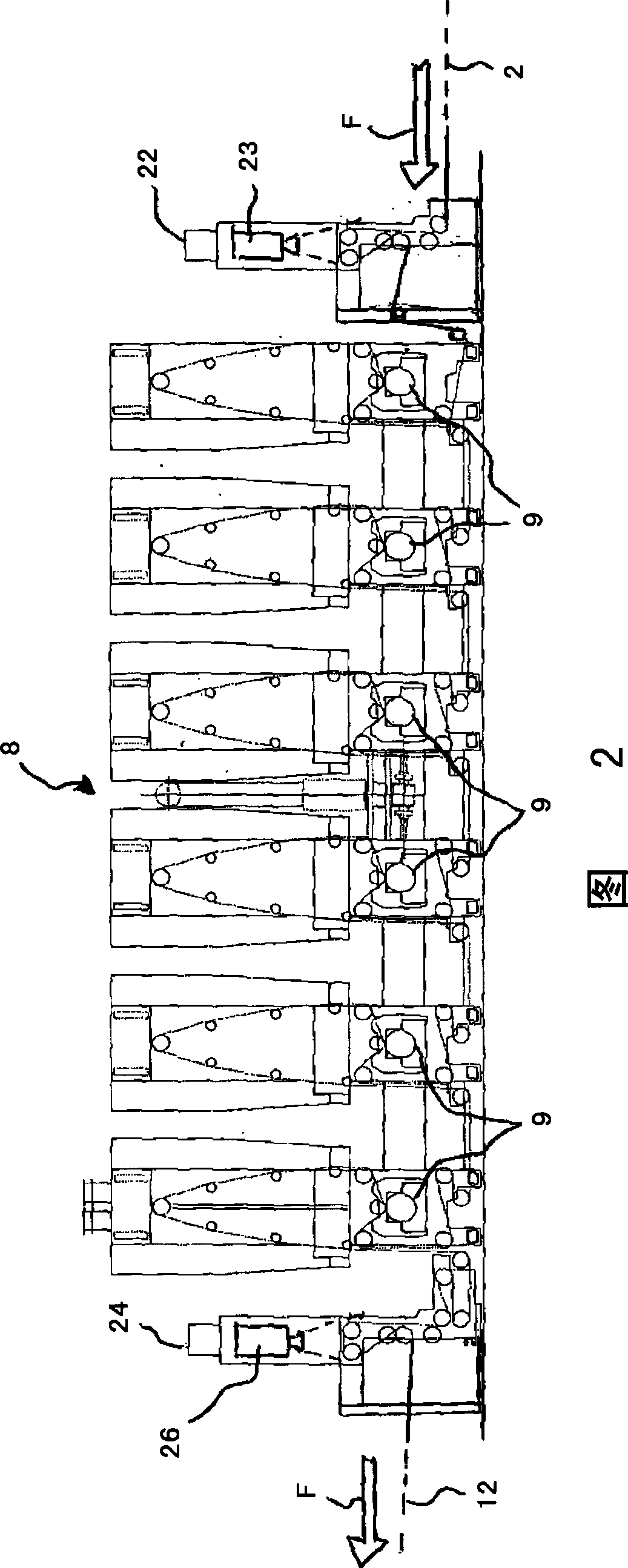

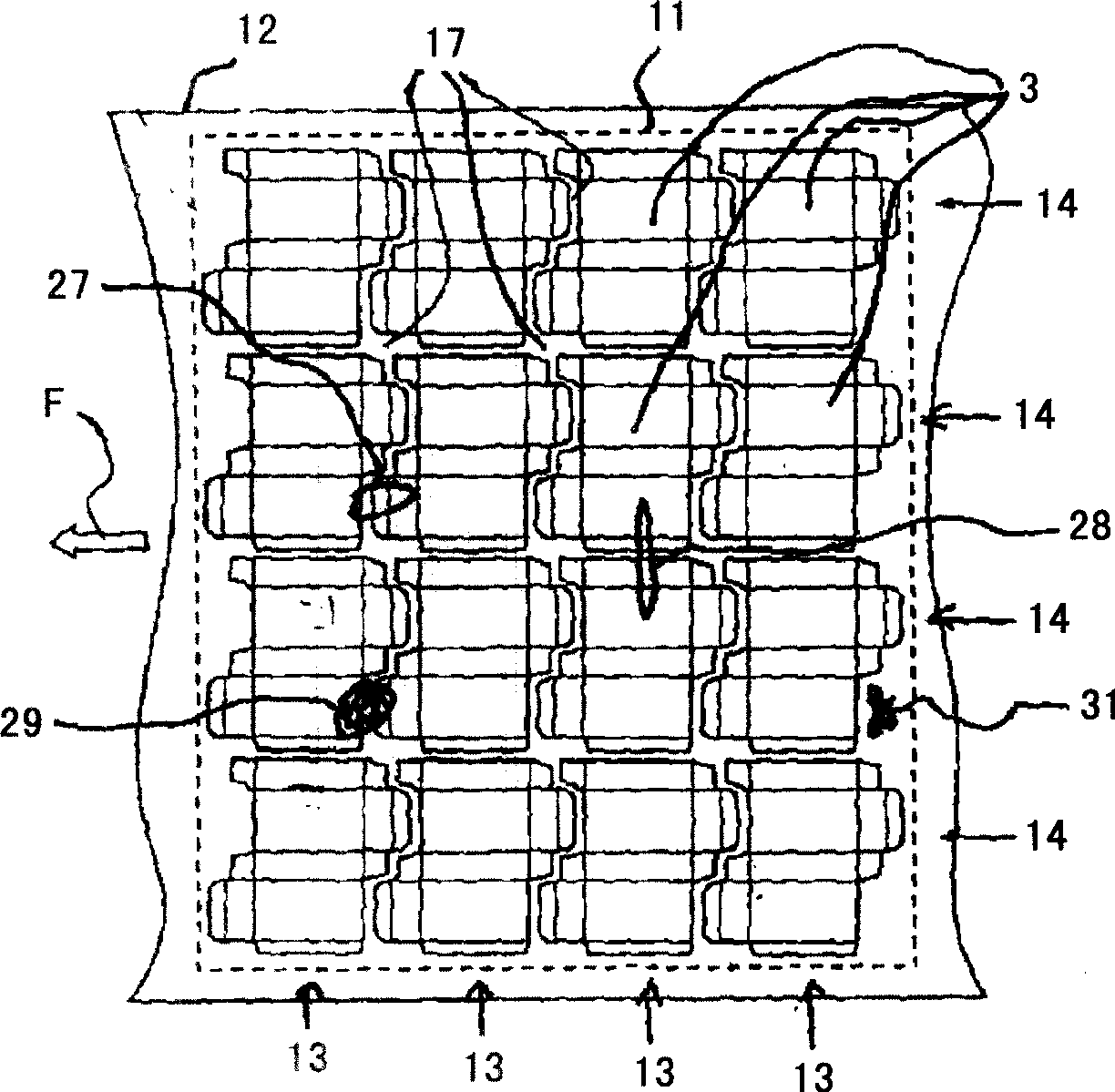

[0051] As shown in FIGS. 1 and 2 , the packaging is produced on a packaging line 1 . The production starts from an initial continuous substrate, ie a raw web 2 such as cardboard, and goes through various successive stages, which will be generally described below. The packaging line 1 is used to manufacture boxes 3 which can be folded and glued to form packages.

[0052] In a first stage, the coil 4 of the raw coil 2 is unrolled by means of a coil uncoiler 6 holding the coil 4 . The feed station 7 can then adjust the tension in the raw web 2 and advance the raw web 2 to a processing machine, described here as a printing press 8 in this example. The advancing direction of the raw web 2 (arrow F in FIGS. 1 to 3 ) forms the upstream and downstream directions.

[0053] In a second stage, the raw web 2 is printed and then allowed to dry as it passes through the printing press 8 . The web 2 passes successively through a plurality of printing units 9 , in this case six, in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com