Float valve sealability detection device

A sealing detection and float valve technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve the problems of unstable detection pressure, decreased accuracy, and distorted detection results. , to achieve the effect of improving detection speed, fast assembly and disassembly speed, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with specific drawings, but it should be understood that the detailed description herein does not constitute a limitation on the protection scope of the present invention.

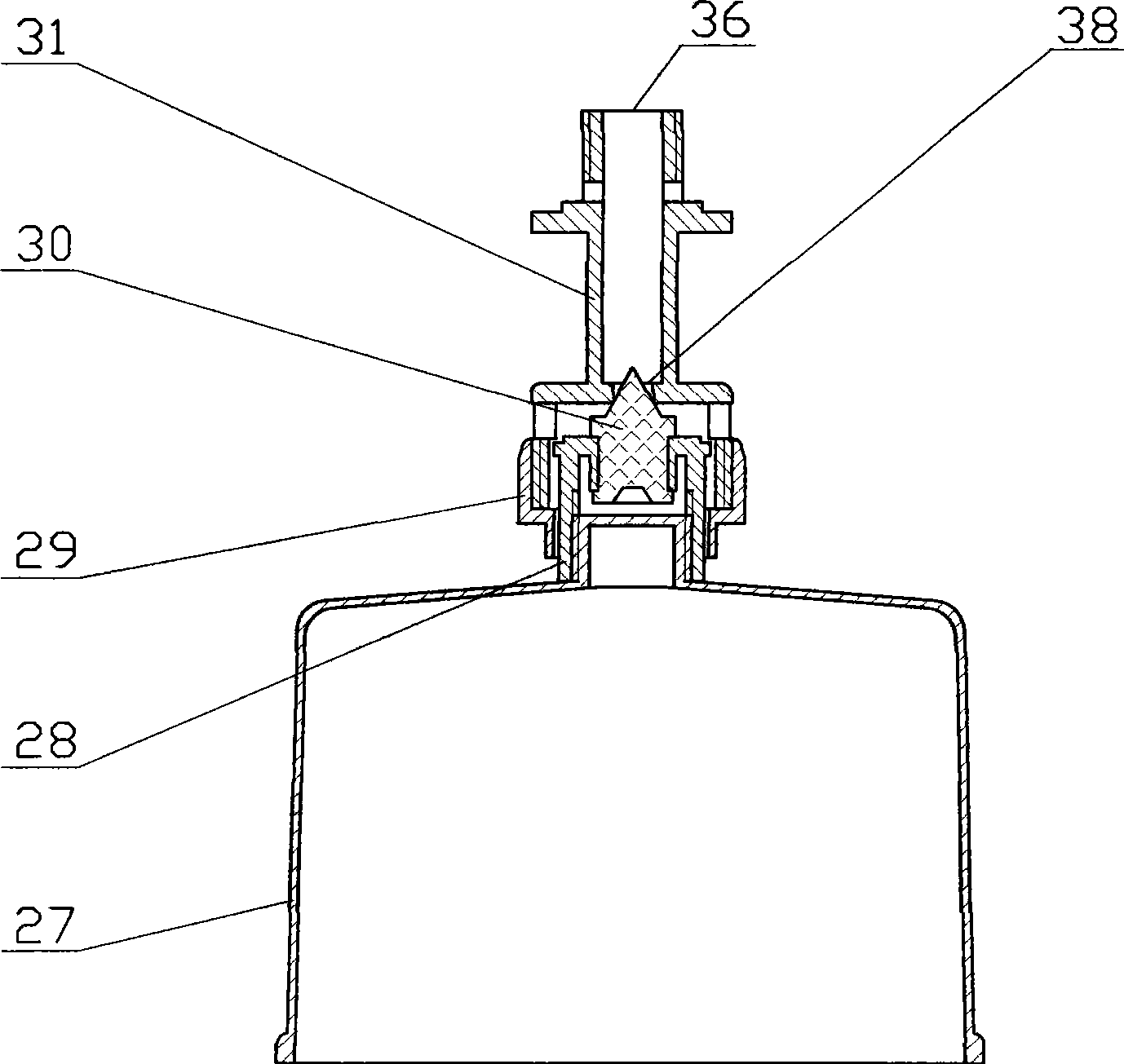

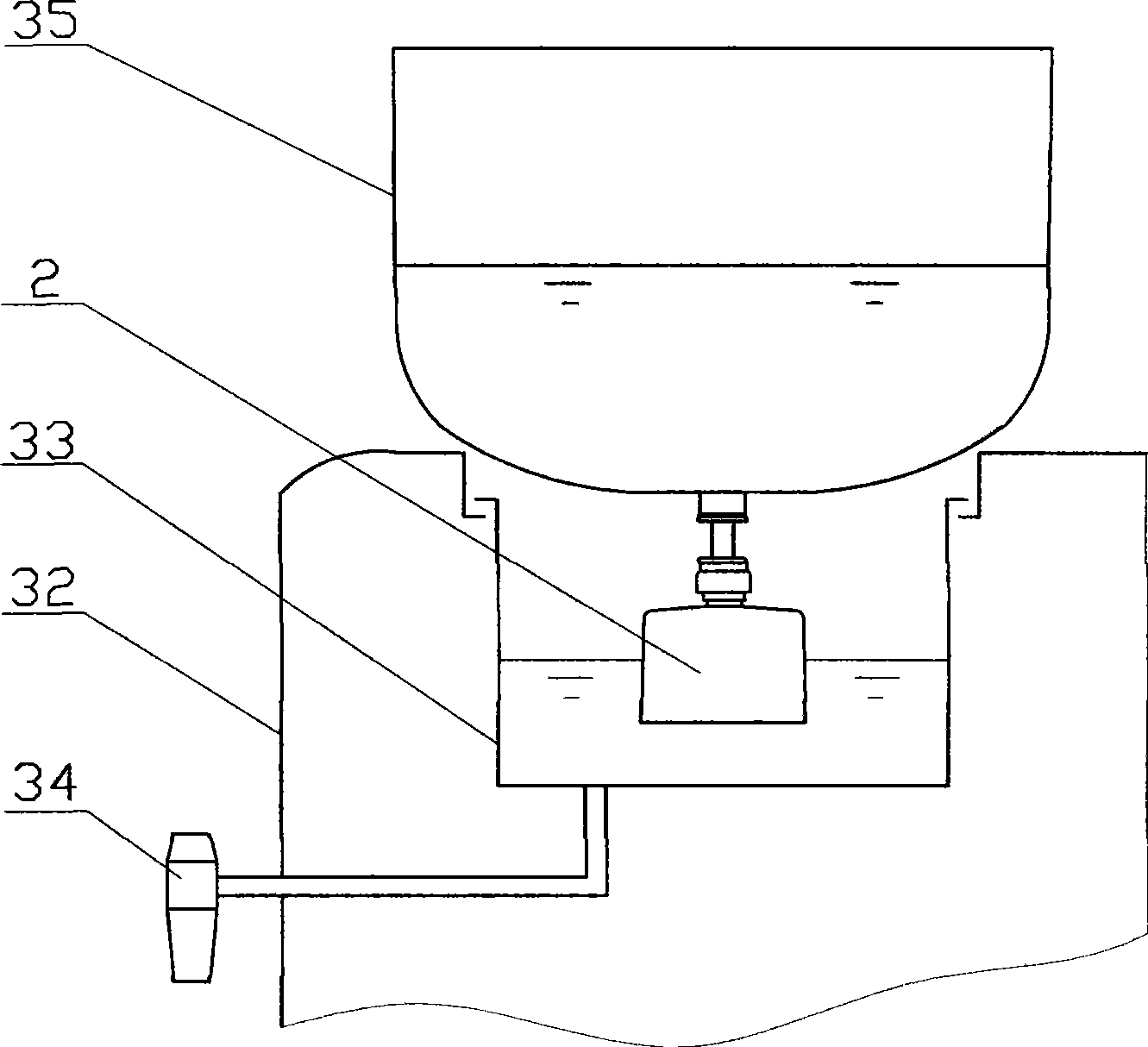

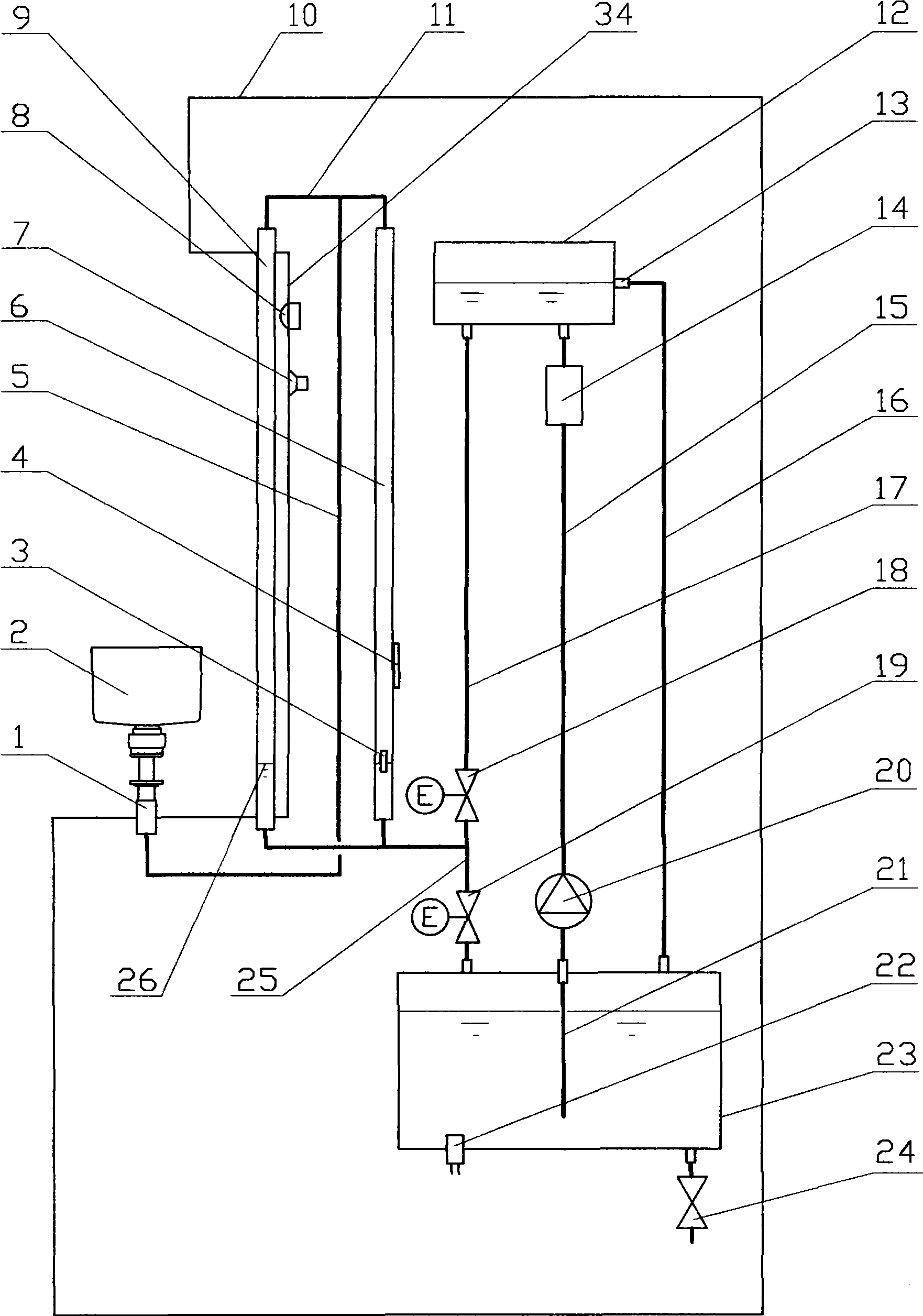

[0044] figure 1 It is a structural schematic diagram of the float valve on the special water purifier for drinking fountains in the prior art. combine figure 1 As shown, the float valve includes a valve body (31), a float (27), a valve disc (28), a tapered gasket (30) and a limit nut (29), and the valve disc (28) is connected to the float (27) through threads. connection, the conical gasket (30) is fixedly assembled on the disc (28), the limit nut (29) is connected with the valve body (31) through threads, and the float (27), valve disc (28) and conical gasket (30) The assembled assembly can slide up and down in the lower cavity of the valve body (31), the stop nut (29) has a positioning and guiding effect on the assembly, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com