Cable-spun device of ring spinning frame

A spinning frame and cable-type technology, applied in textiles and papermaking, etc., can solve problems such as easy deformation, poor stability, and device position changes, and achieve the effects of no friction loss, reliable operation, and stable rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

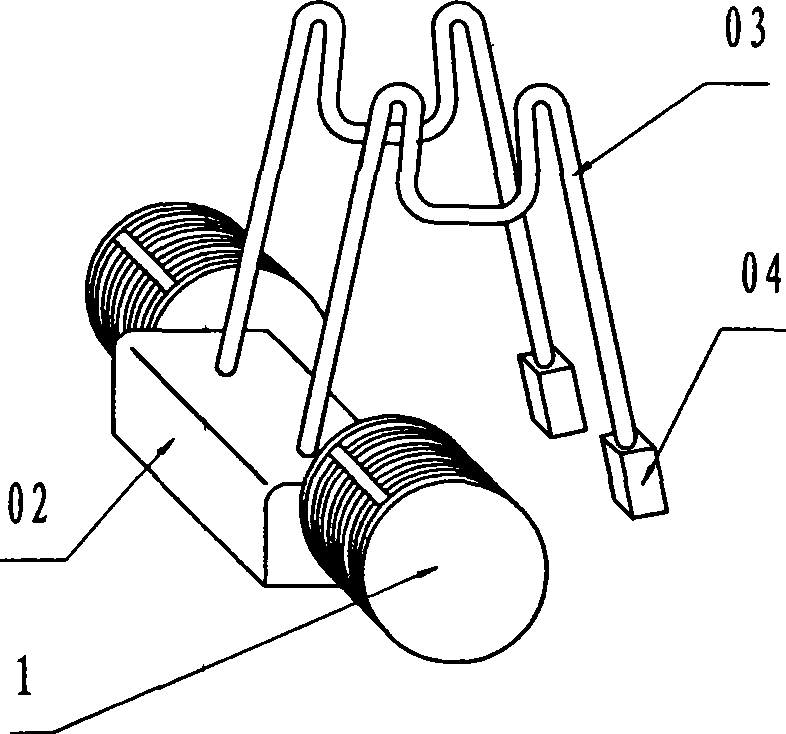

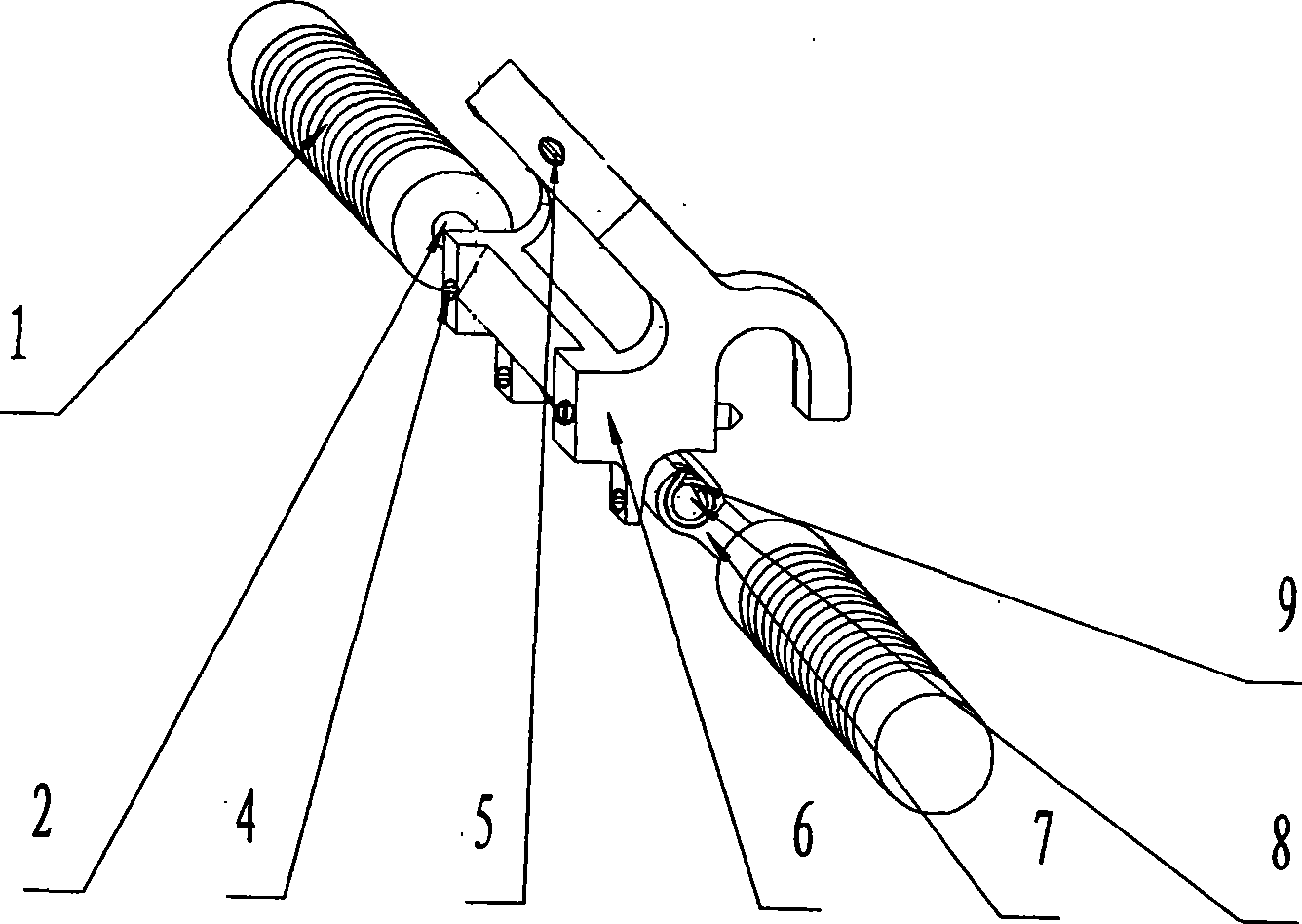

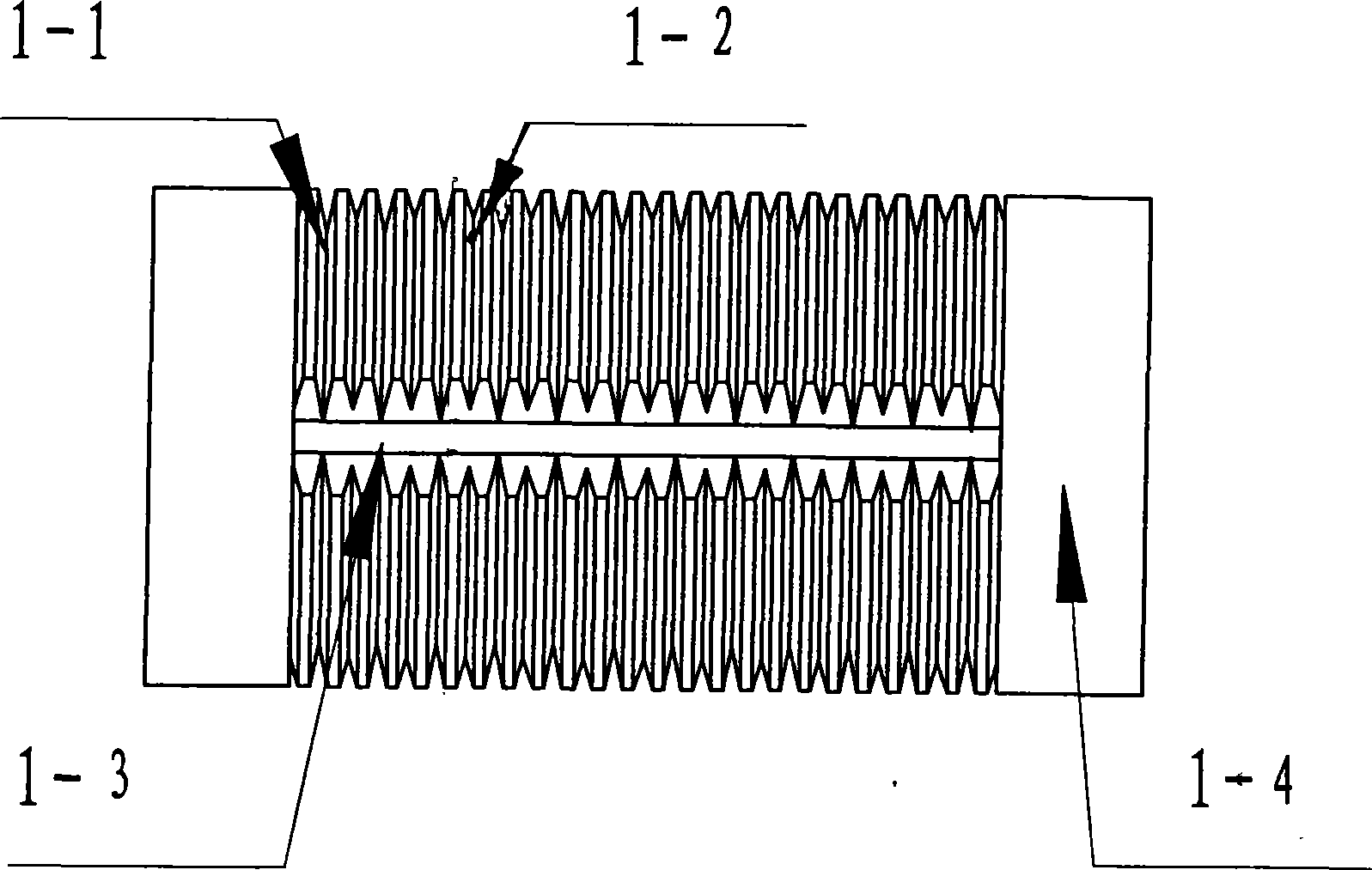

[0026] see Figure 2~4 As shown, the overall structure of the cable spinning device includes a splitting wheel 1, splitting wheel shaft 2, front top roller 3 of ring spinning frame, set screw 4, positioning screw 5, fixing clip 6, swing seat 7, swing seat shaft 8, Torsion spring 9, front roller 10 of ring spinning frame, front top roller shaft 11 of ring spinning frame and front top roller claw 12 of ring spinning frame. Wherein, the splitting wheel 1 includes a deep splitting groove 1-1, a shallow splitting groove 1-2, a transition section 1-3 and a splitting wheel base 1-4.

[0027] During spinning, buckle the hook of the fixing clip 6 on the front top roller shaft 11 of the ring spinning frame, at this time, the set screw 5 on the fixing clip 6 is naturally above the front top roller claw 12 of the ring spinning frame, tighten The set screw 4 ensures that the fixing clip 6 reliably clamps the front top roller shaft 11 of the ring spinning frame. According to the needs of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com