Beer sterilized bottle filler

A filling machine and beer technology, applied in the field of light industrial machinery, can solve the problems of inability to realize aseptic filling function, high investment and use costs, complicated cleaning and sterilization, etc., and achieve easy automation control, investment cost and use cost. Low, avoid secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

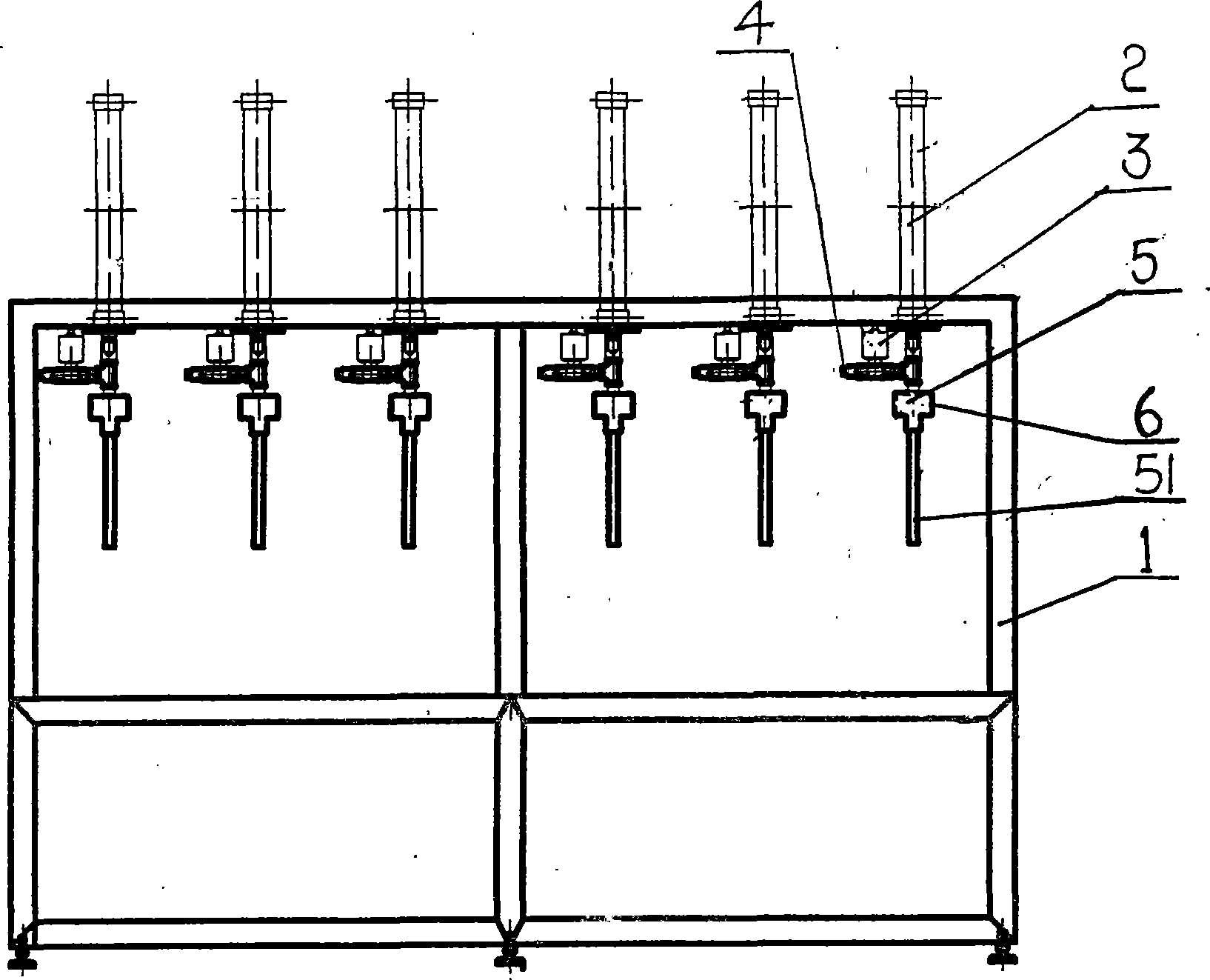

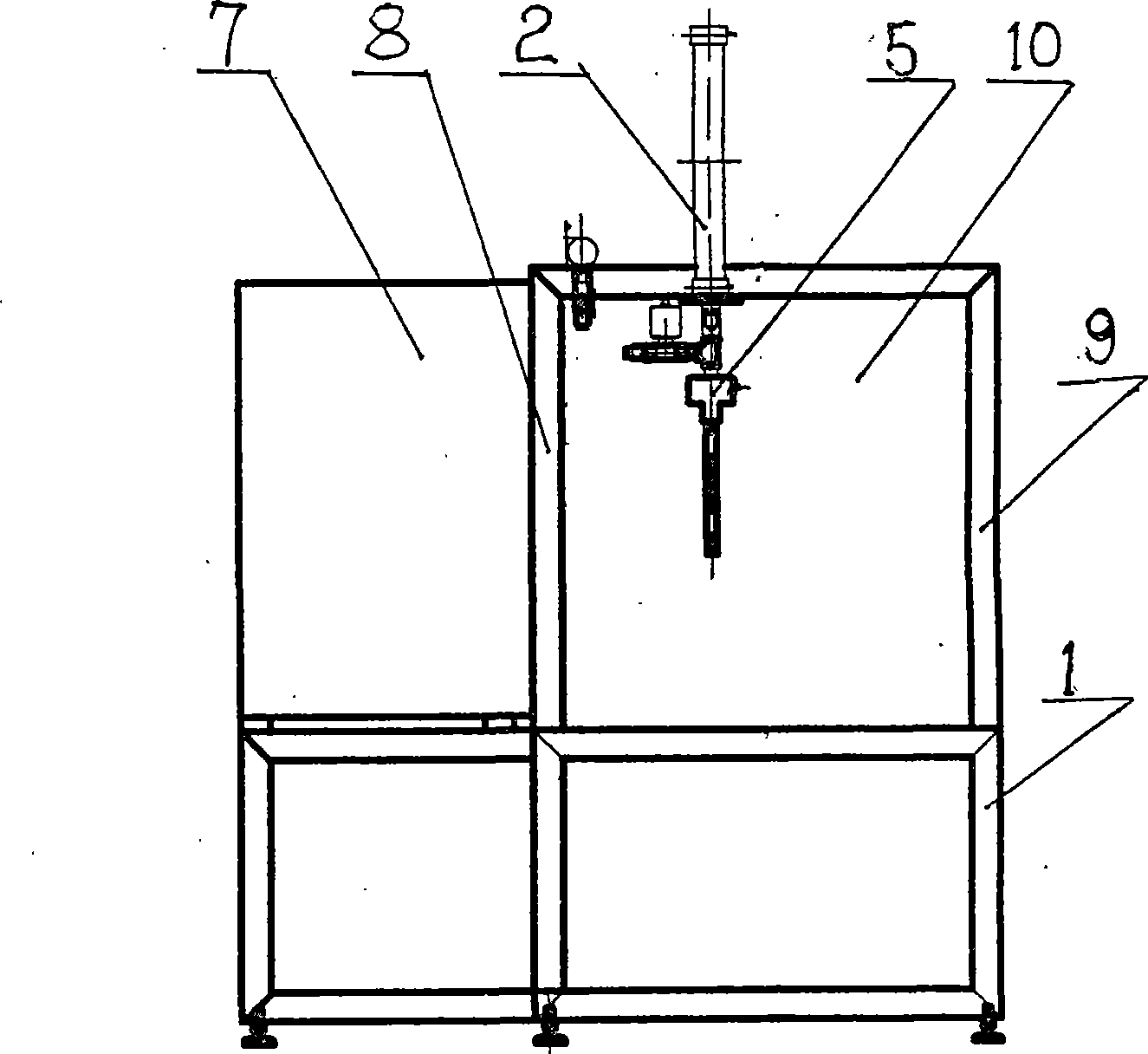

[0016] Such as figure 1 , figure 2 shown. A beer aseptic filling machine includes a frame 1 and a filling mechanism arranged on the frame. The filling mechanism is composed of multiple filling units arranged on the frame, and the multiple filling units are arranged in a line to improve the filling efficiency.

[0017] The filling unit includes a cylinder 2, a solenoid valve 3, a filling head 5 and a long pipe 51. The filling head 5 is connected to the wine inlet 4 controlled by the solenoid valve 3. When injecting wine, the wine inlet 4. One end is connected to the external wine delivery pipe, and the other end is connected to the long pipe 51 whose bottom end is close to the bottom of the filling container 11. Such as image 3 The lower end where the filling head is combined with the long tube is provided with a gap 52, and the upper end where the filling head is combined with the long tube is tightly combined. The gap 52 communicates with the gas port 6 provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com