Manufacturing method for complete quartz crystal resonator and quartz crystal resonator

A quartz crystal and manufacturing method technology, applied in electrical components, impedance networks, etc., can solve problems such as shortages, and achieve the effect of simple and clear structure, suitable for low-cost manufacturing, and reduced height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

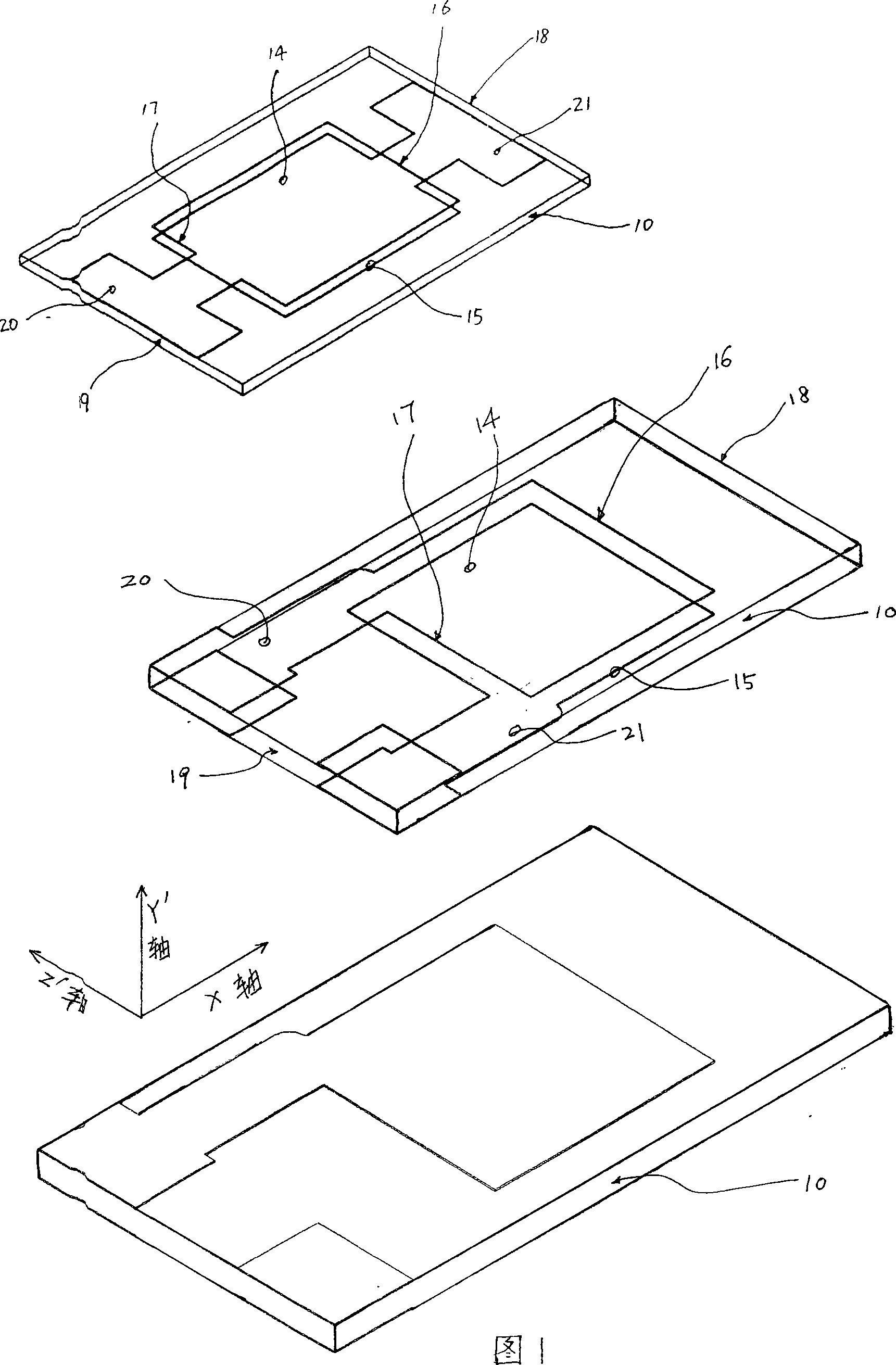

[0051] FIG. 1 shows a rectangular piezoelectric quartz crystal resonator plate 10 . In the present invention, the long side of the resonator plate 10 is parallel to the X-axis, which is just the crystal characteristic axis and the AT cutting direction of the quartz crystal, and this AT-cut quartz crystal is generally used for high-frequency quartz crystal resonance device. The width of the resonator plate 10 is parallel to the Z' axis, and the thickness is parallel to the Y' axis.

[0052] In order not to specifically limit the present invention, the common size of the resonator piece 10 includes the length range: between 0.5mm-12mm, such as 7.5mm. Width range: between 0.5mm-5.5mm, such as 5mm. The thickness depends on the resonant frequency according to the following relationship

[0053] t=1.67 / F (Formula 1)

[0054] t stands for thickness, unit mm, F stands for resonant frequency, single MHz, the resonant frequency is usually between 1MHz-200MHz.

[0055] In order to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com