Method for manufacturing large caliber aspherical mirror

A technology of aspheric mirror and manufacturing method, which is applied in the optical field using large-diameter aspheric mirrors, can solve the problems of difficult manufacturing, long cycle, and high cost, and achieve the effects of shortening the manufacturing cycle, reducing the difficulty of processing and testing, and alleviating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

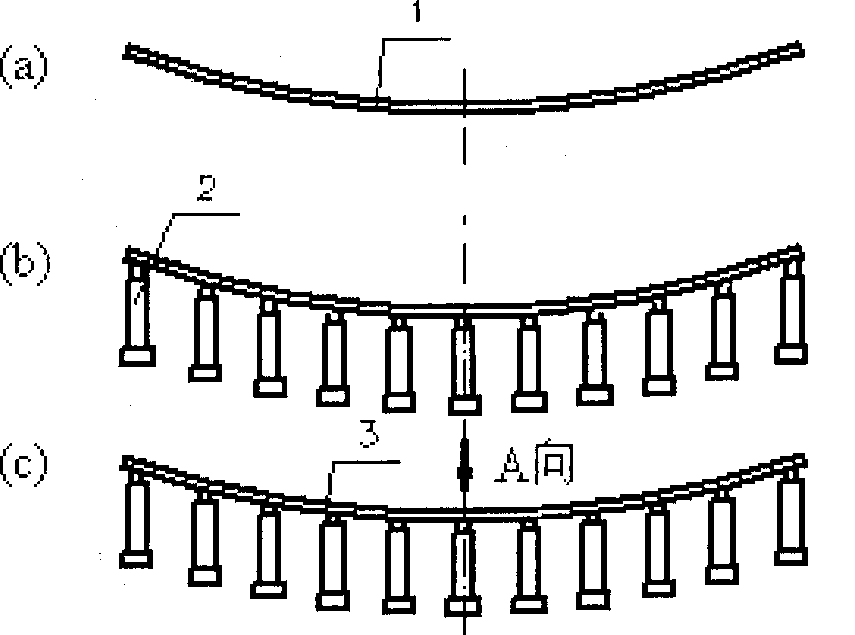

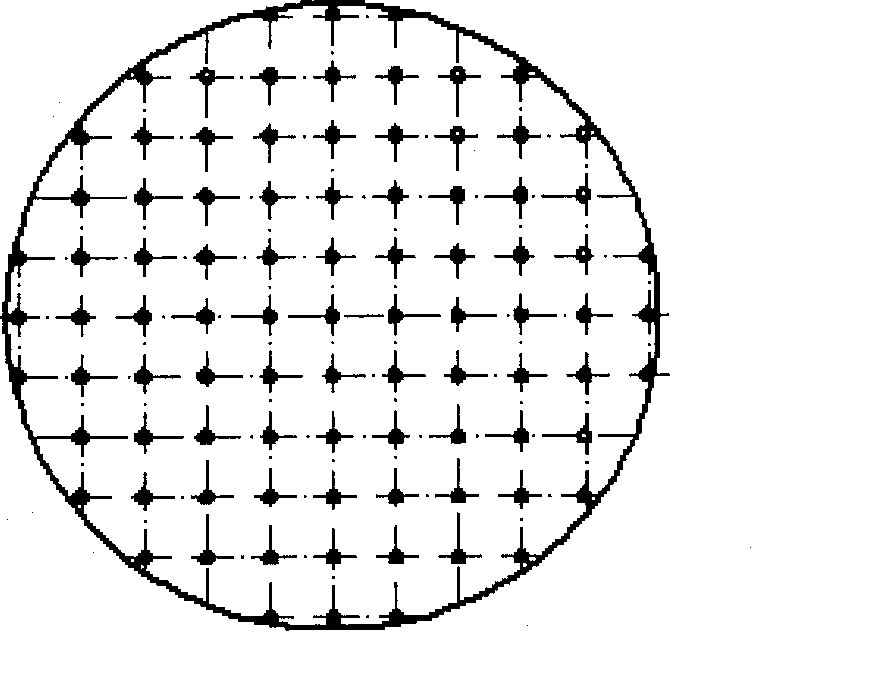

[0073] Embodiment 1: A kind of manufacturing method of large diameter aspheric mirror, see attached figure 1 , the specific steps are: (1) finish processing a qualified ultra-thin spherical mirror 1, (2) place it on the actuator assembly 2 to keep the radius and surface shape accuracy of the spherical mirror, (3) pass a certain number of regular arrangements The actuator exerts a displacement on the mirror surface, causing the mirror surface to be forcibly deformed and deformed into the required aspheric mirror 3 . attached figure 2 A schematic diagram of the actuator arrangement using a square uniform arrangement is shown.

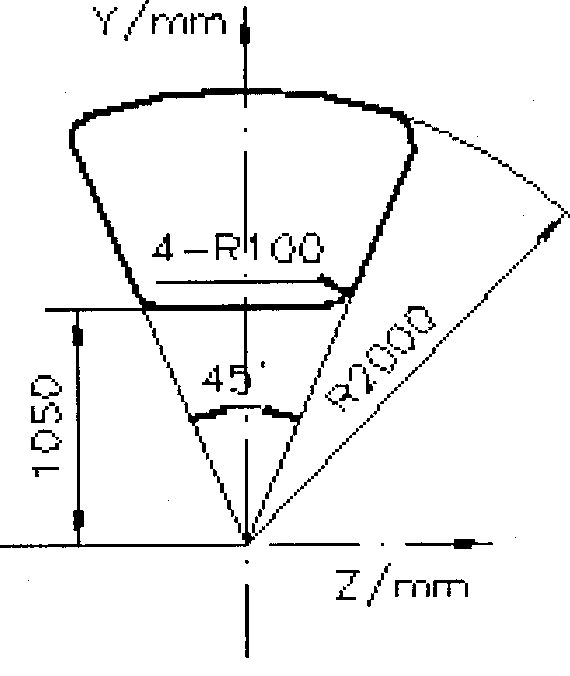

[0074] See attached image 3 As shown, the ultra-thin mirror is aspherically shaped. The equation of the aspheric surface is

[0075]

[0076] where c=1 / R 0 , R 0 =9760mm, k=-0.98. The material of the ultra-thin mirror is Zerodur, and its elastic modulus is 90.3×10 9 N / m 2 , Poisson's ratio is 0.24, the allowable stress is 10MPa, and the thic...

Embodiment 2

[0104] Embodiment 2: Comparison of asphericity gradient conversion rate method and other arrangement methods.

[0105] Refer to the example of forming an aspheric surface of an ultra-thin mirror in Example 1 to compare the arrangement methods of the actuators.

[0106] In the case of no gravity, the actuator layout, surface shape residual diagram and von Mises stress moiré diagram obtained by using the asphericity gradient transformation rate method are shown in Figure 13 ~ Figure 15 .

[0107] The actuator arrangement, surface residual and von Mises stress moiré diagram obtained by the square method are shown in Figure 21 ~ Figure 23 .

[0108] The actuator arrangement, surface residual and von Mises stress moiré diagram obtained by using the ring method to meet the surface accuracy are shown in Figure 24 ~ Figure 26 .

[0109] See Figure 27 ~ Figure 29 . Correction means that the actuators are spaced differently on the border than in the central area.

[0110] See...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com