Uniaxial tension loading unit for testing concrete carbonizing performance under tensile stress and testing method

A loading device and uniaxial stretching technology, applied in the direction of measuring devices, strength characteristics, instruments, etc., to achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the first step, a circular PVC pipe with a length of 300 mm and a diameter of 100 mm is used as a mold for making a concrete cylindrical specimen; The depth is 4cm. The concrete is formed by means of layered vibration, and the formwork is removed after one day of forming, and it is taken out after curing to the age required by the test.

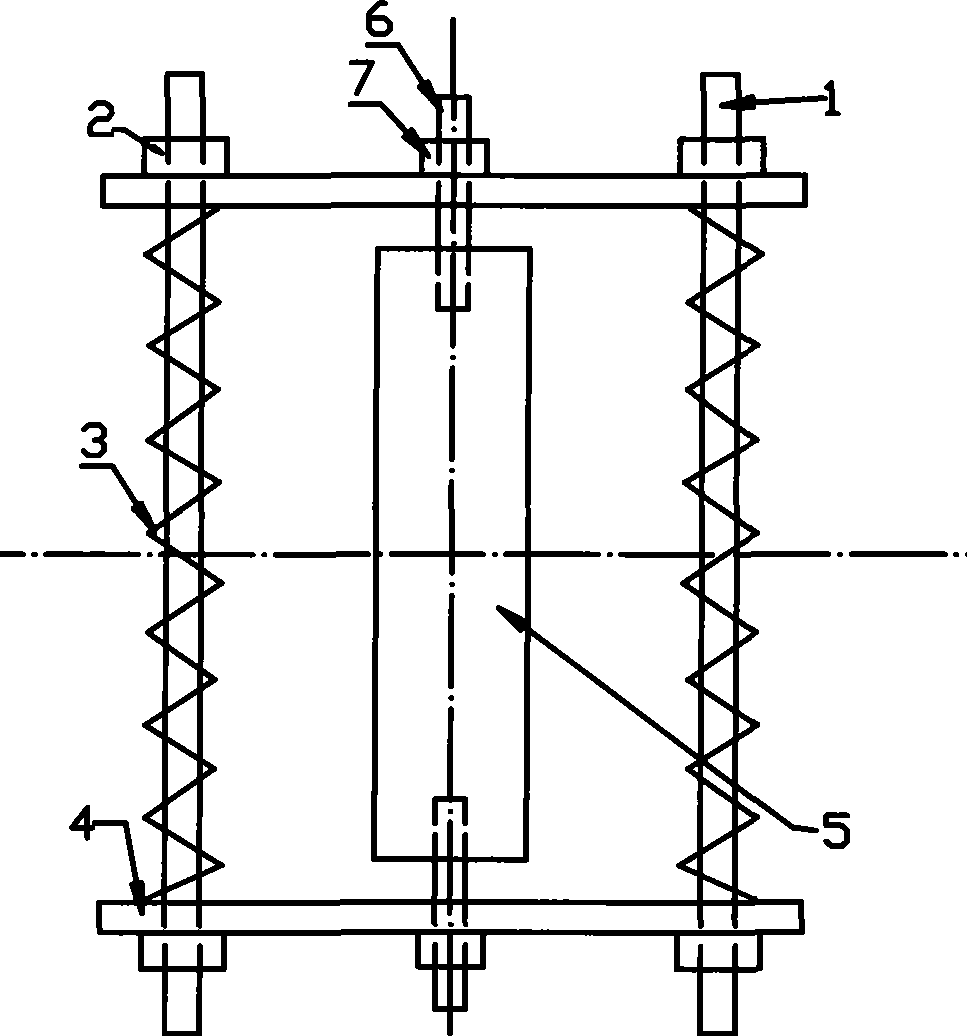

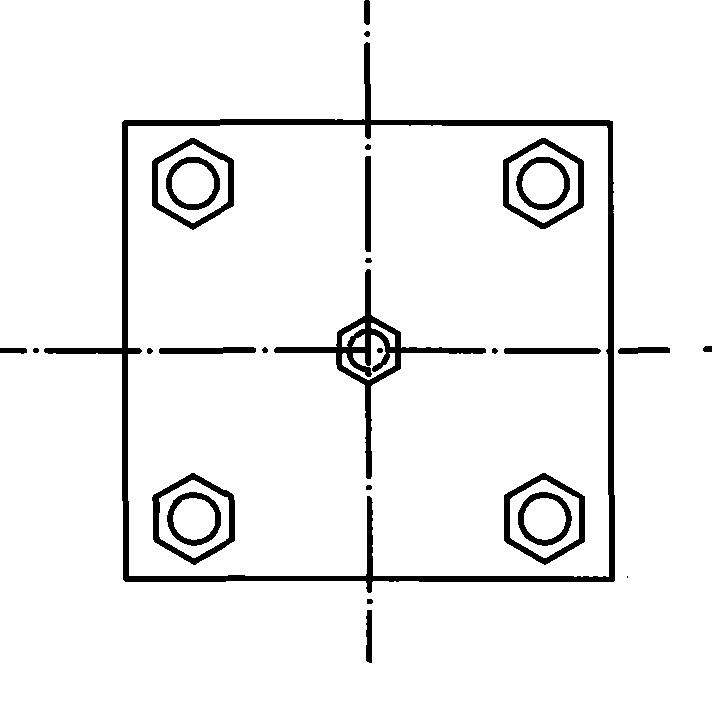

[0022] In the second step, four steel pipes are inserted into the four holes at the four corners of the lower steel plate, and four springs with the same characteristic parameters are placed on it, and the prepared cylindrical concrete specimen is placed on the lower steel plate, so that The pre-embedded bolts on the lower end surface of the concrete specimen pass through the hole at the central axis of the lower steel plate, and then put the upper steel plate on the same place, apply pressure to the spring to make the upper steel plate closely contact with the upper surface of the test piece, and tighten the steel plate at the four...

Embodiment 2

[0027] In the first step, a cuboid specimen is formed by a 100×100×300 cube triple mold. When forming, embed the embedded bolts at the central axis positions at both ends of the specimen, and the embedment depth is 7cm. Concrete is formed by layered vibration. The formwork is removed after one day of forming, and it is taken out after curing to the age required by the test. The curing age is determined according to different tests. Seal the two opposite faces and the upper and lower end faces of the cuboid specimen with epoxy resin, leaving only two opposite faces.

[0028] The second step, such as figure 1 and figure 2 As shown, four steel pipes are inserted into the four holes at the four corners of the lower steel plate, and four springs with the same characteristic parameters are placed on them, and the prepared rectangular concrete specimen is placed on the lower steel plate, so that the concrete The pre-embedded bolts on the lower end of the test piece pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com