Assembling aluminium-wood energy saving door and window

A prefabricated, aluminum-wood technology, used in windows/doors, door/window fittings, wing fan frames, etc., can solve the problems of inability to heat and dampen, prevent noise, easy to rust hinges, large load-bearing torque, etc., to reduce The effect of fan bearing capacity, flexible opening and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

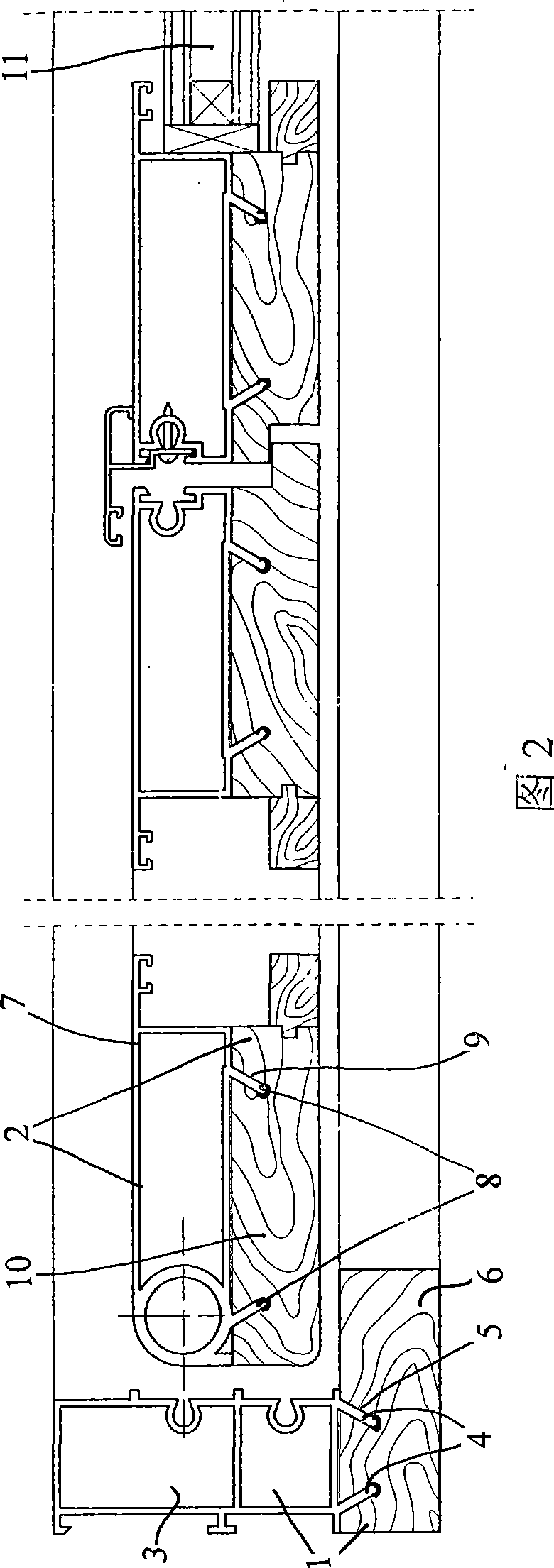

[0021] Fig. 1 and Fig. 2 provide the structural schematic diagram of the present embodiment 1. Referring to FIG. 1 and FIG. 2 , the assembled aluminum-wood energy-saving door and window in this embodiment 1 includes an outer frame 1 and a fan frame 2 . The outer frame 1 is composed of an aluminum frame layer 3, an aluminum frame connecting strip assembly 4 integrated with the aluminum frame layer in an internal splayed arrangement (or an outer splayed arrangement), and an outer splayed assembly 4 matched with the aluminum frame connecting strip assembly (also can be arranged) The solid wood frame connection groove assembly 5 that is arranged in horoscope) is formed by the solid wood frame layer 6 that is assembled into one by the solid wood frame connection groove assembly and the aluminum frame connection bar assembly and the aluminum frame layer. The fan frame 2 is composed of an aluminum fan frame layer 7, an aluminum fan frame connecting strip assembly 8 that is arranged i...

Embodiment 2

[0025] image 3 , Figure 4 Figure 2 of this embodiment is given. Embodiment 2 is basically the same as Embodiment 1. The difference is that there are upper shaft holes 12 and lower shaft holes 13 at the upper and lower ends of the fan frame respectively, springs 14 are respectively housed in the upper and lower shaft holes, and the shafts 15 and 16 at the upper and lower ends of the fan frame stretch into the upper and lower shafts respectively. Contact with spring in the lower rotating shaft hole, there are upper rotating shaft seat 17 and lower rotating shaft seat 18 that cooperate with upper and lower rotating shafts respectively on the upper and lower ends of the outer frame, so that outer frame and fan frame are rotatably connected. Fan frame and outer frame are positioned at rotating shaft and bearing 19 is housed. Glass 20 is housed on the fan frame.

Embodiment 3

[0027] Figure 5 A schematic structural diagram of Embodiment 3 is given. Present embodiment 3 is basically the same as embodiment 2, and the difference is that a plurality of wooden strips 21 are housed on the fan frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com