Nano hydroxyl magnesium silicate powder and preparation method thereof

A technology of hydroxymagnesium silicate and powder, which is applied in chemical instruments and methods, petroleum industry, inorganic pigment treatment, etc. It can solve the problems affecting product quality and commerciality, poor powder consistency, and limited use, etc., and achieves convenient operation , Purity improvement, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

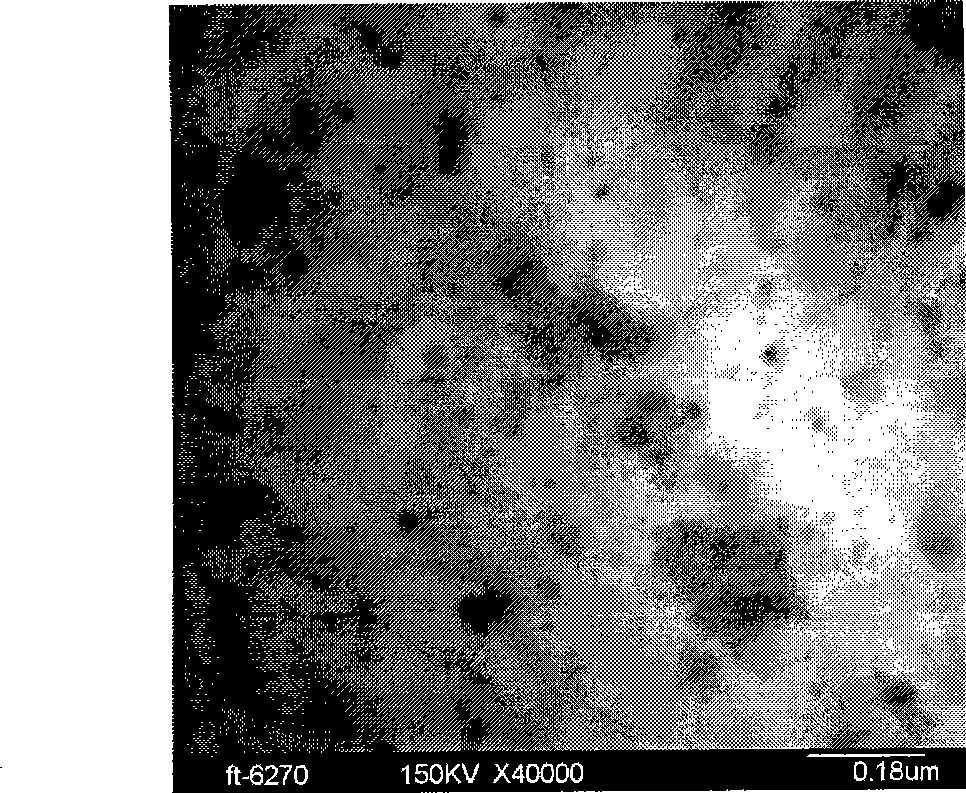

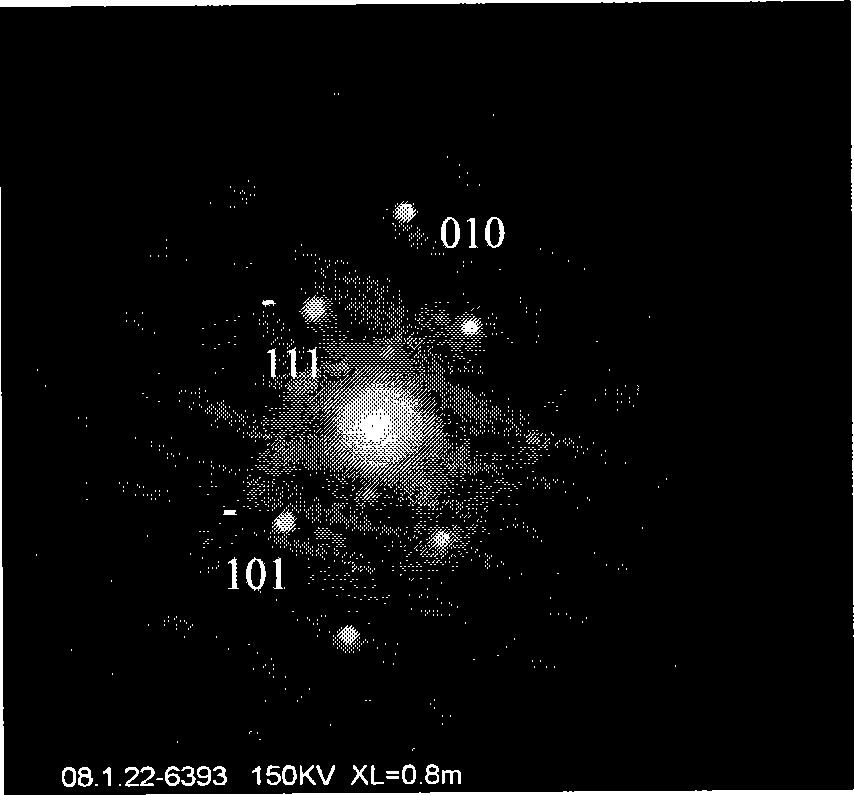

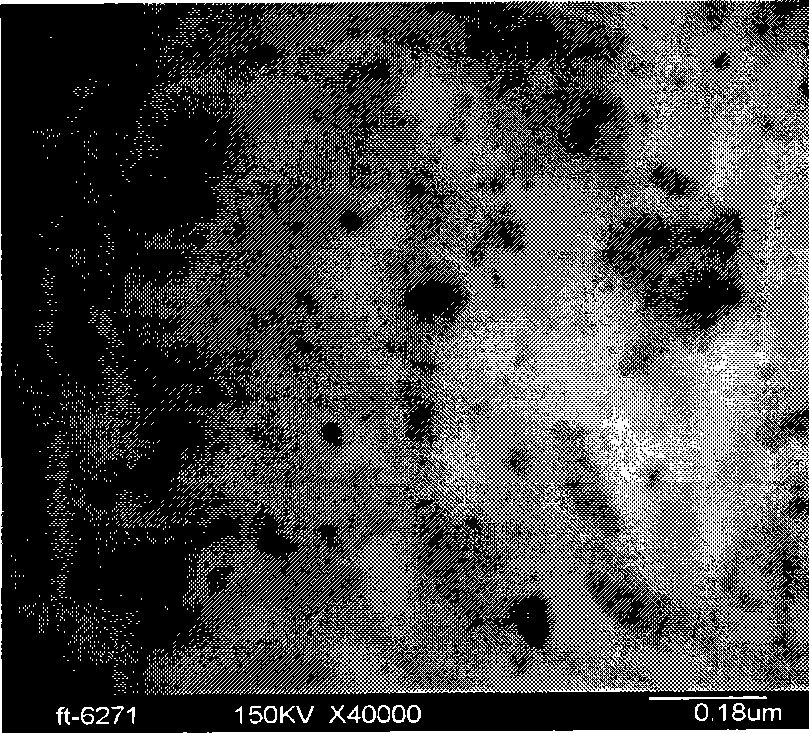

Image

Examples

Embodiment 1

[0038] Raw material ratio:

[0039] Diatomaceous earth 10g (5%)

[0040] Magnesium Sulfate 30g (15%)

[0041] Sodium Hydroxide 20g (10%)

[0042] Sodium Peroxide 140g (70%)

[0043] Specific preparation method:

[0044] (1) Magnesium sulfate is put into drying oven and dried at 200 DEG C for 2 hours to remove crystal water;

[0045] (2) Sodium hydroxide is prepared into a supersaturated strong alkali solution of 1g / ml, then the diatomite, magnesium sulfate and sodium peroxide are added to the supersaturated strong alkali solution of sodium hydroxide successively and mixed uniformly, And add ball mill in ball mill for 10 hours;

[0046] (3) The mixed solution after ball milling is centrifuged at a centrifugal speed of 5000 rpm for 30 minutes. After filtration, the dry matter is dried at 200°C for 2 to 3 hours, and finally prepared into nano-hydroxymagnesium silicate powder .

[0047] Product performance testing:

[0048] The nanometer hydroxymagnesium silicate powder th...

Embodiment 2

[0050] Raw material ratio:

[0051] Diatomaceous earth 20g (20%)

[0052] Magnesium Sulfate 25g (25%)

[0053] Sodium Hydroxide 10g (10%)

[0054] Sodium Peroxide 45g (45%)

[0055] Specific preparation method:

[0056] (1) Magnesium sulfate is put into drying oven and dried at 200 DEG C for 2 hours to remove crystal water;

[0057] (2) Sodium hydroxide is prepared into a supersaturated strong alkali solution of 1g / ml, then the diatomite, magnesium sulfate and sodium peroxide are added to the supersaturated strong alkali solution of sodium hydroxide successively and mixed uniformly, And add ball mill in ball mill for 10 hours;

[0058](3) The mixed solution after ball milling is centrifuged at a centrifugal speed of 5000 rpm for 45 minutes. After filtration, the dry matter is dried at 200°C for 2 to 3 hours, and finally prepared into nano-hydroxymagnesium silicate powder .

[0059] Product performance testing:

[0060] The nanometer hydroxymagnesium silicate powder tha...

Embodiment 3

[0062] Raw material ratio:

[0063] Diatomaceous earth 10g (10%)

[0064] Magnesium Sulfate 15g (15%)

[0065] Sodium Hydroxide 20g (20%)

[0066] Sodium peroxide 55g (55%)

[0067] Specific preparation method:

[0068] (1) Magnesium sulfate is put into drying oven and dried at 200 DEG C for 2 hours to remove crystal water;

[0069] (2) Sodium hydroxide is prepared into a supersaturated strong alkali solution of 1g / ml, then the diatomite, magnesium sulfate and sodium peroxide are added to the supersaturated strong alkali solution of sodium hydroxide successively and mixed uniformly, And add ball mill in ball mill for 10 hours;

[0070] (3) The mixed solution after ball milling is centrifuged at a centrifugal speed of 5000 rpm for 60 minutes, and the filtered dry matter is dried at 200°C for 2 to 3 hours, and finally prepared into nano-hydroxymagnesium silicate powder .

[0071] Product performance testing:

[0072] The nanometer hydroxymagnesium silicate powder that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com