Block moulder with failure-safe system and working method thereof

A block forming machine and automatic technology, applied in the direction of ceramic forming machines, manufacturing tools, etc., can solve the problems of automatic troubleshooting of non-component failures and low cost performance, and achieve the effect of saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

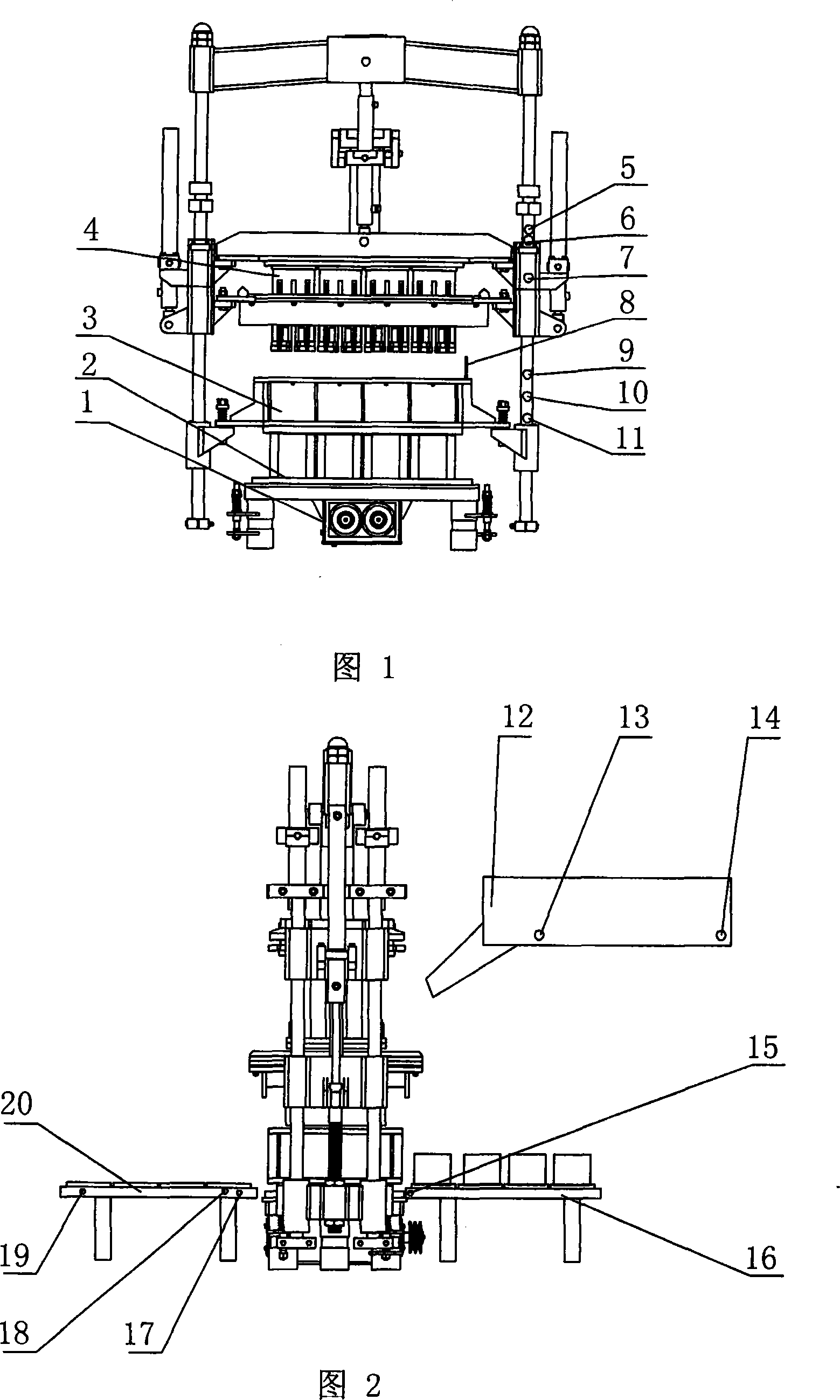

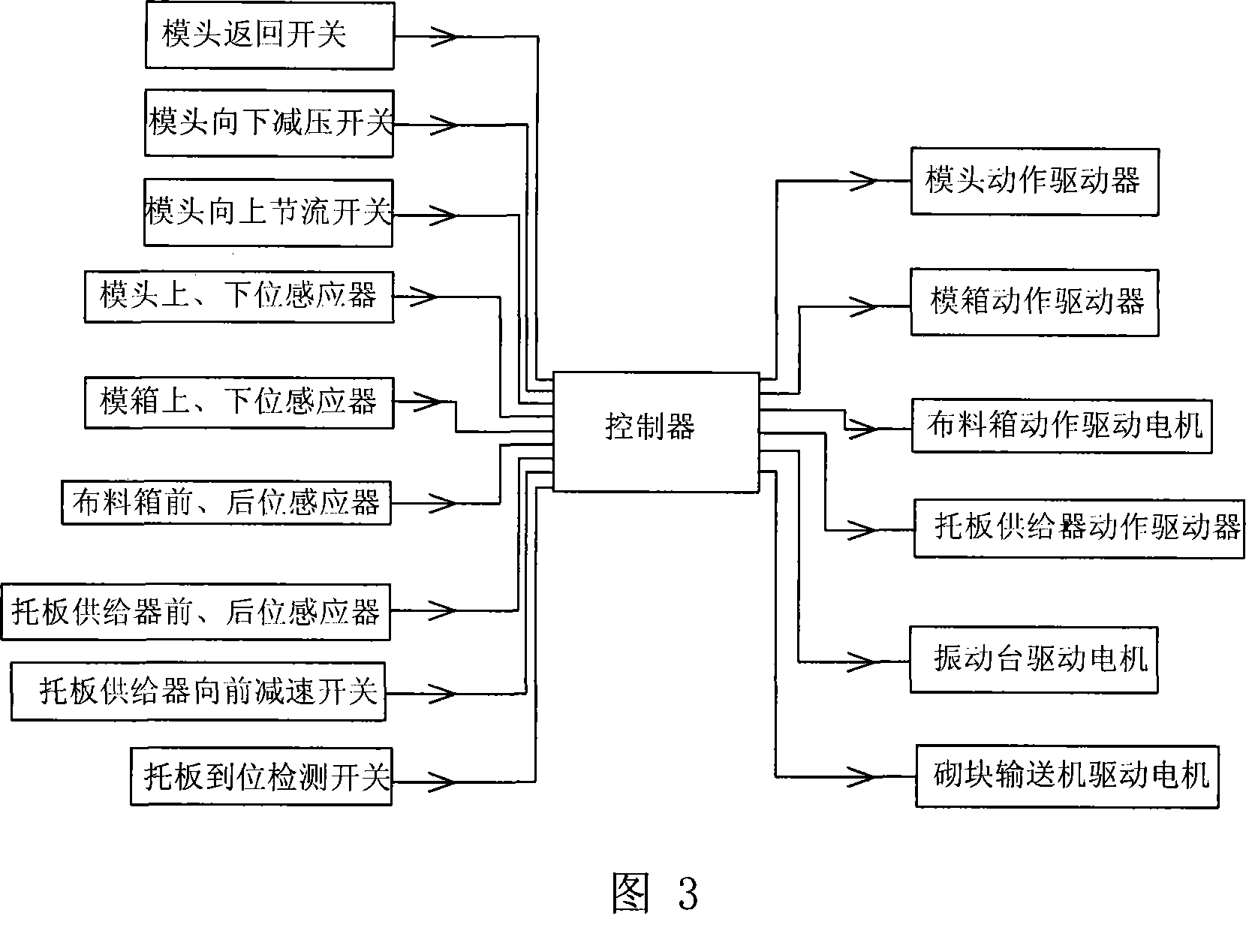

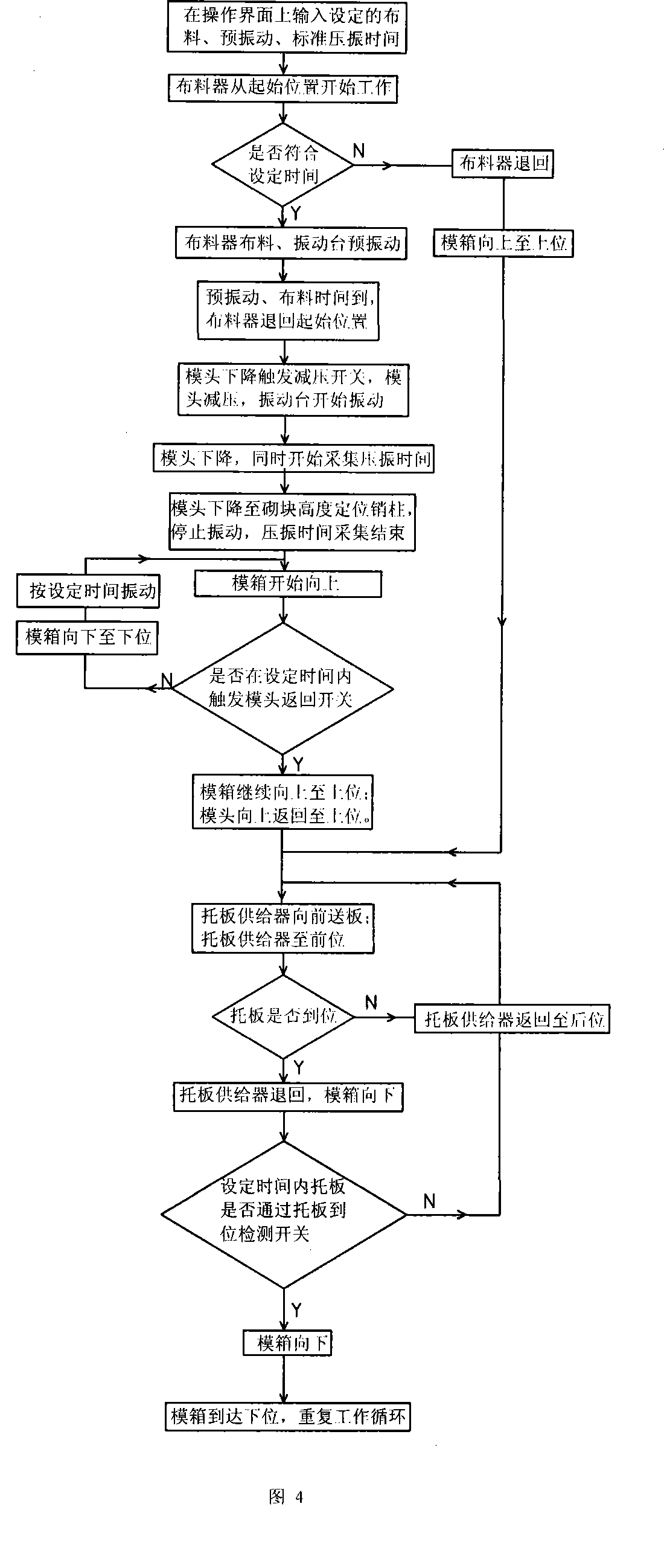

[0035] Such as figure 1 , 2 , the block forming machine with automatic troubleshooting system of the present invention includes a die head 4, a die box 3, a distribution box 12, a pallet feeder 20, and a block height positioning device is provided between the mold case 3 and the die head 4. The pin 8 is provided with a number of sensors on the running path of the die head 4, the mold box 3, the distribution box 12, the pallet feeder 20, and the block conveyor 16 of the block forming machine; it also includes a controller , the controller is composed of a command device, a central processing unit, a main board, an execution program that records the actions of each component of the command machine, and a program memory that compares the input setting time of each action with the actual running time of each action; the command device includes a display The display of the operation interface and the keyboard for inputting commands; the main board is provided with a timing circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com