Horizontal type billet shearing machine

A shearing machine and bar material technology, applied in the direction of shearing devices, shearing machine equipment, shearing machine accessories, etc., can solve the problems of large blanking length error, fragile fuselage, and huge structure, etc., to reduce down Material strength, high energy efficiency ratio, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

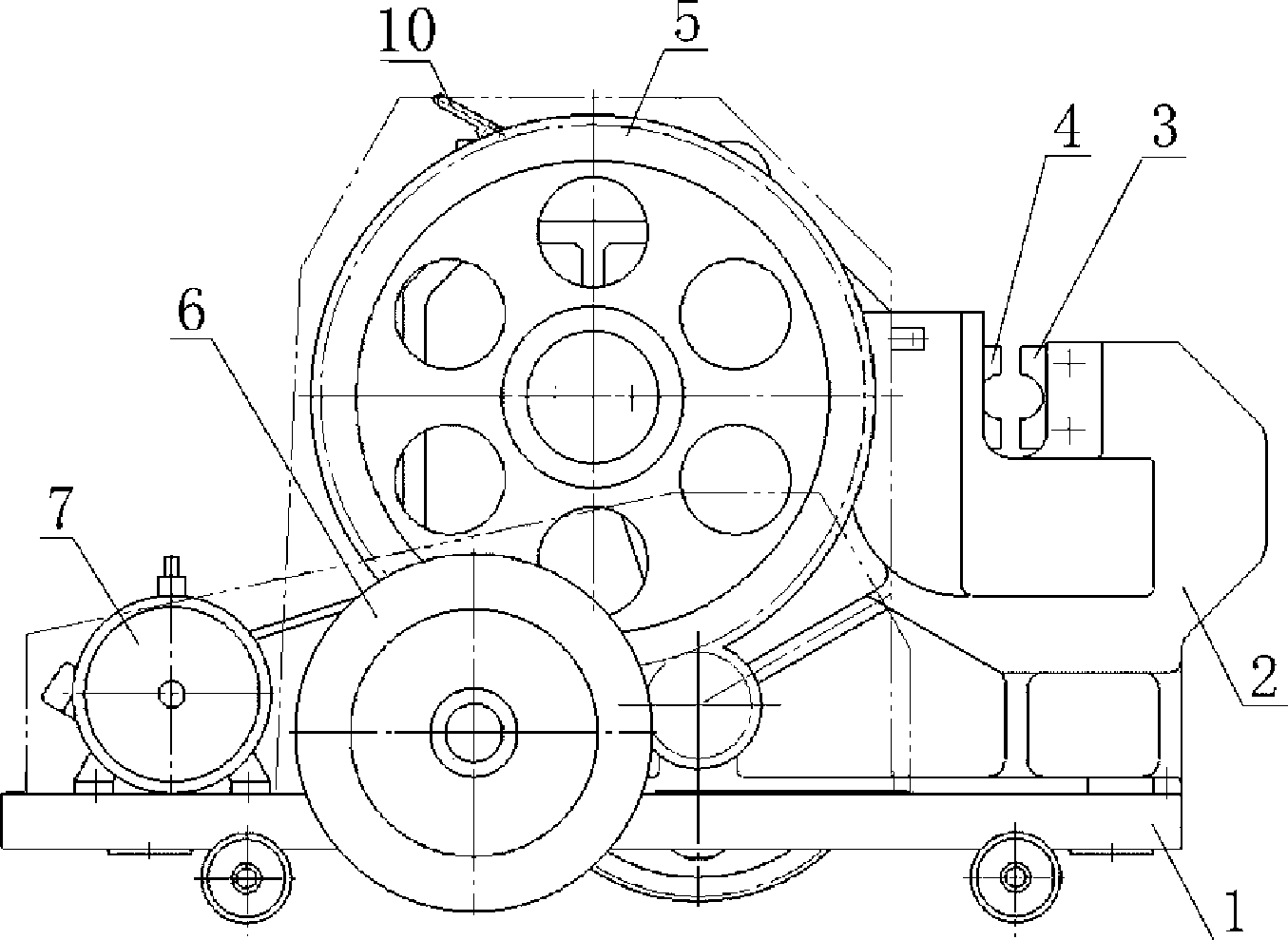

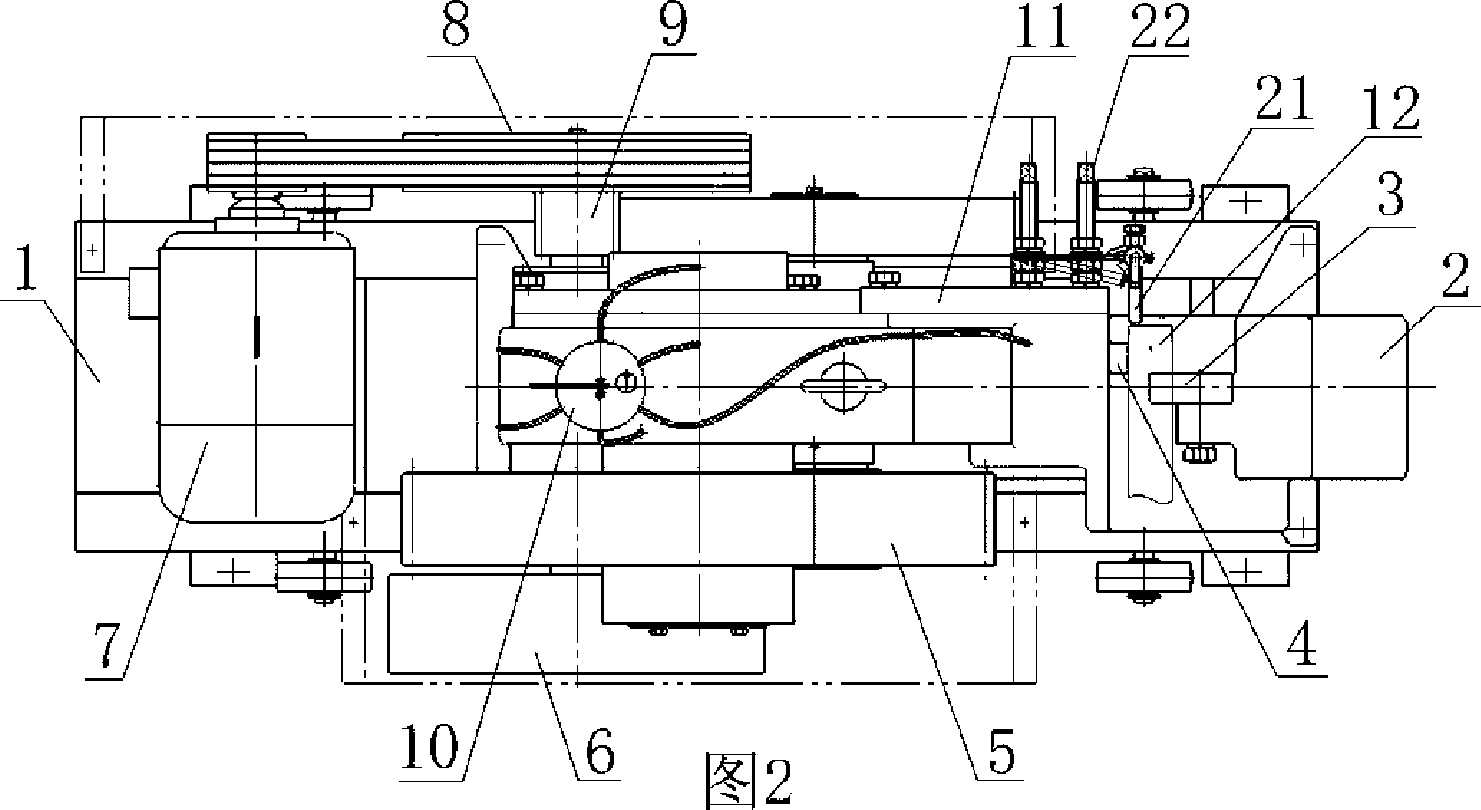

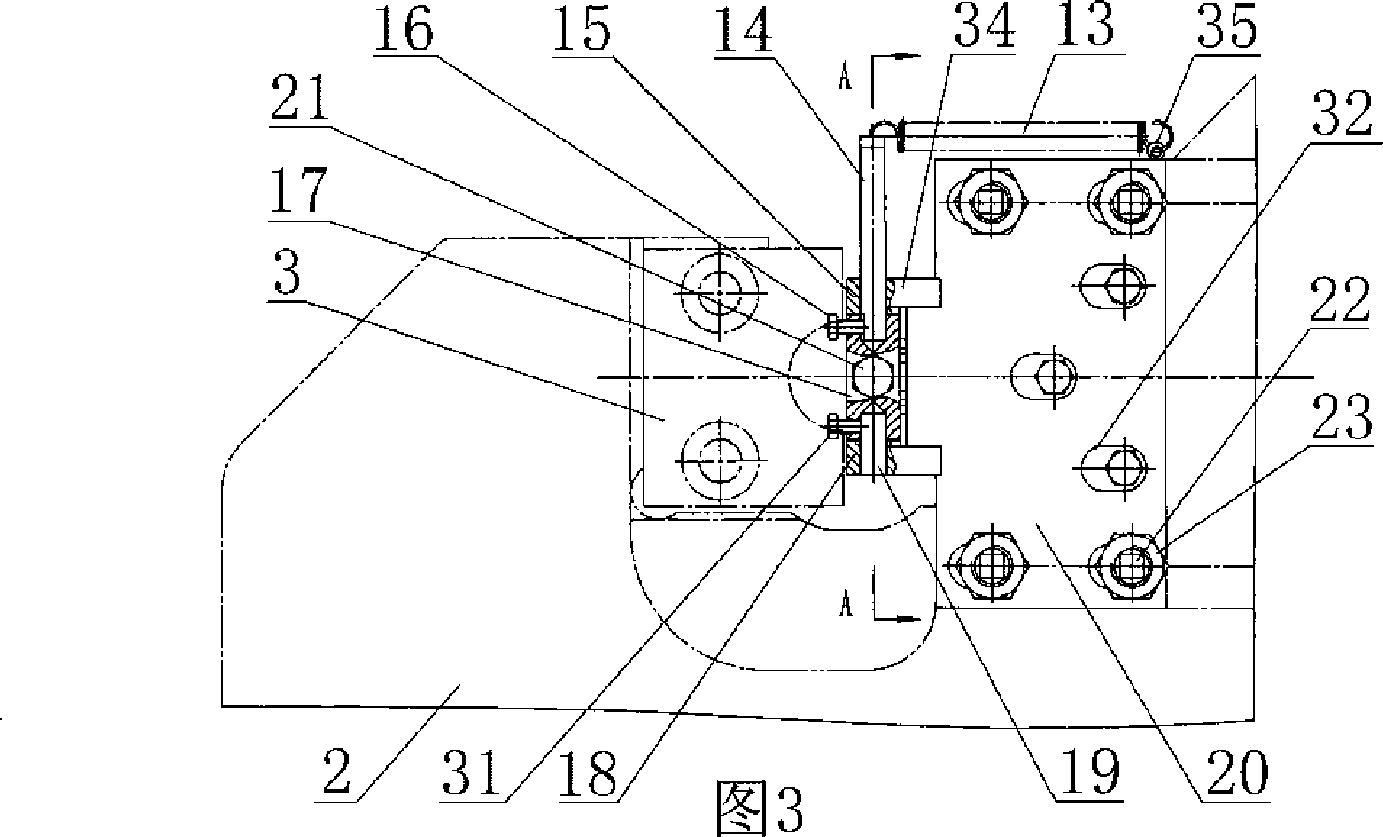

[0032] Examples see figure 1 -Shown in Fig. 6, this horizontal bar shearing machine fixes fuselage 2 on support 1, and fuselage 2 is as the main body of shearing machine, and the top of fuselage 2 has centralized lubricating oil cup 10, to the whole The transmission system and the crankshaft slider mechanism are lubricated centrally. One end of the fuselage 2 is fixed with a fixed knife plate 3, the knife edge of the fixed knife plate is horizontally corresponding to the movable knife plate 4, the movable knife plate 4 is fixed on the end of the slider 24 of the crankshaft slider mechanism, and the slideway of the slider 24 It is perpendicular to the bar blank 12 to be cut and arranged horizontally along the fuselage 2. The slider is fixed on the fuselage 2 by the pressure plate 11. The crankshaft 30 of the crank slider mechanism is driven and connected to the motor 7 through the transmission system 5, and the motor 7 is fixed on the machine. The other end of seat 1.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com