Fastening element

一种紧固件、中间区的技术,应用在适用紧固件的手动工具、叠加层的镀覆、螺栓等方向,能够解决铬钢昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

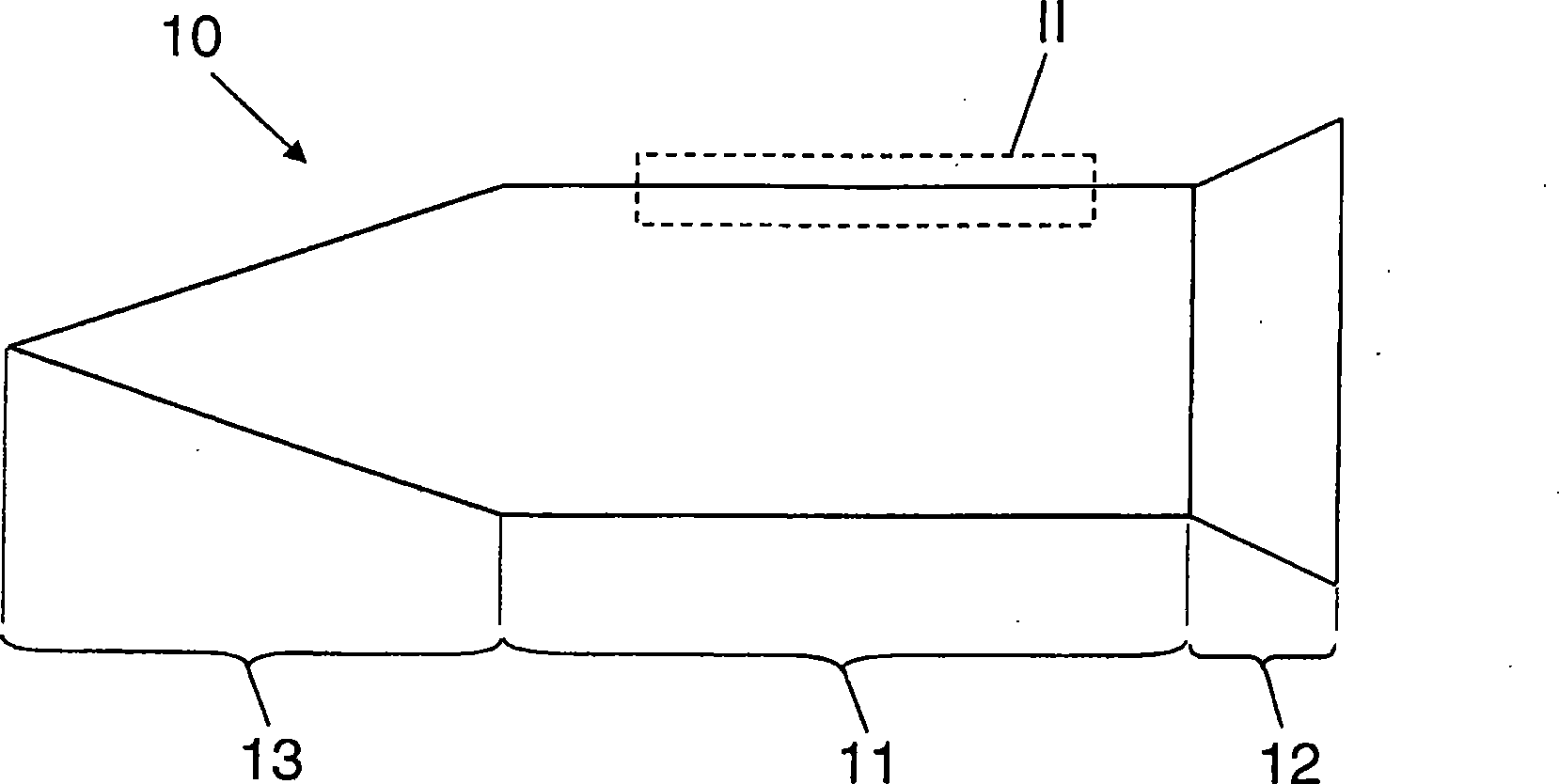

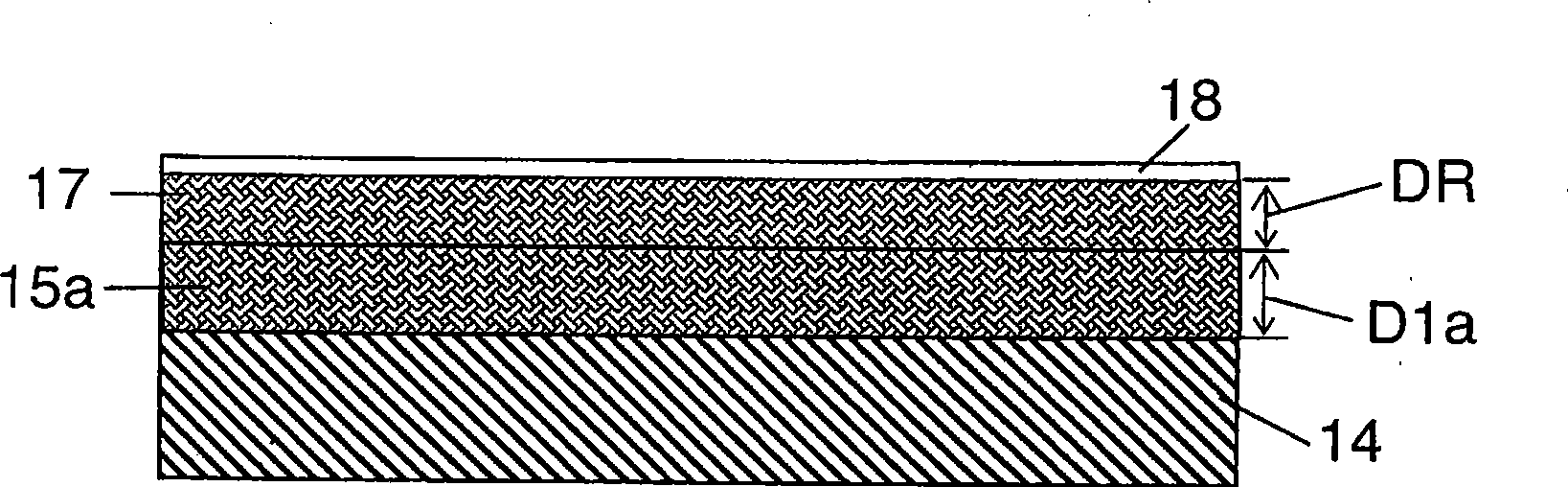

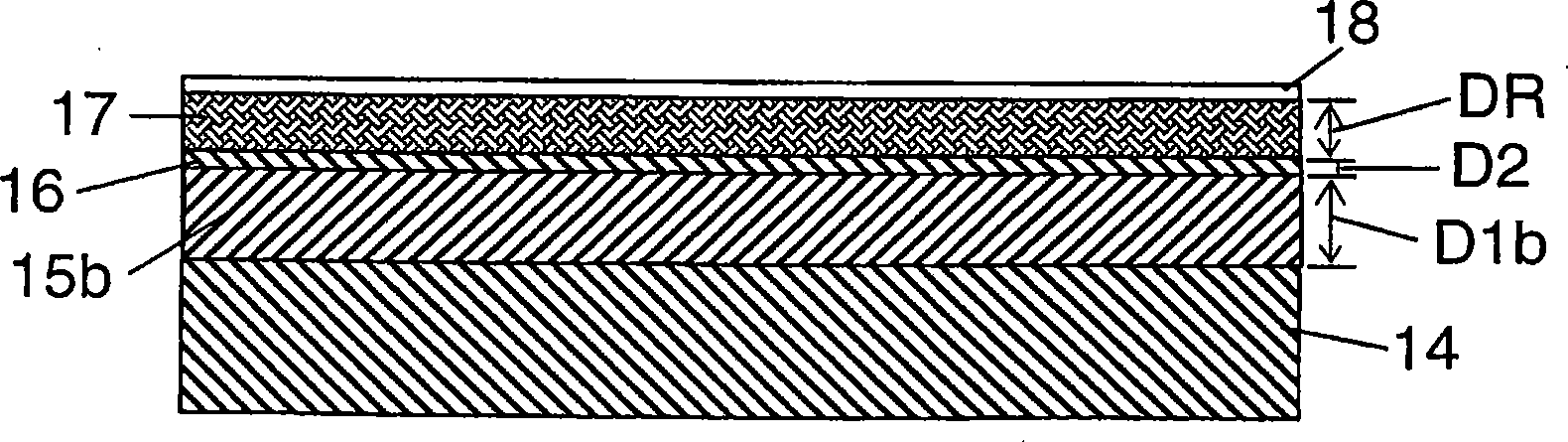

[0026] exist figure 1 and 2 A fastener 10 designed as a nail is shown in . This fastening element 10 has a shaft 11, at one end of which a nail head 12 is formed and at its other end a nail point 13 is formed. Depend on figure 2 As can be seen, the fastener 10 has a core region 14 comprised of a carbonaceous steel having a martensitic or bainitic structure having a hardness between about 30 and 62 HRC. At least in the region of the rod 11 , radially on the outside thereof, an edge region 17 is formed which consists of a first, not too hard, low-carbon steel which has been tempered with a first alloying element. The edge region 17 having a thickness DR between 0.001 mm and 1.0 mm in a direction perpendicular to the surface of the core region 14 has an austenitic structure. Here, the alloying element is a metal selected from the group Ni, Mn, Co, Al, Cr, V or Mo. Inside the edge zone 17, the concentration of alloying elements increases from the inside to the outside. In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com