Bidirectional pre-tensioned rail plate long-surface pedestal production chain

It is a surface pedestal and production line technology, which is applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc. It can solve the problems that prestress is difficult to be effectively monitored and adjusted, product flatness is difficult to guarantee, and production line costs are rising. Effects of maintaining quality, improving production efficiency, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

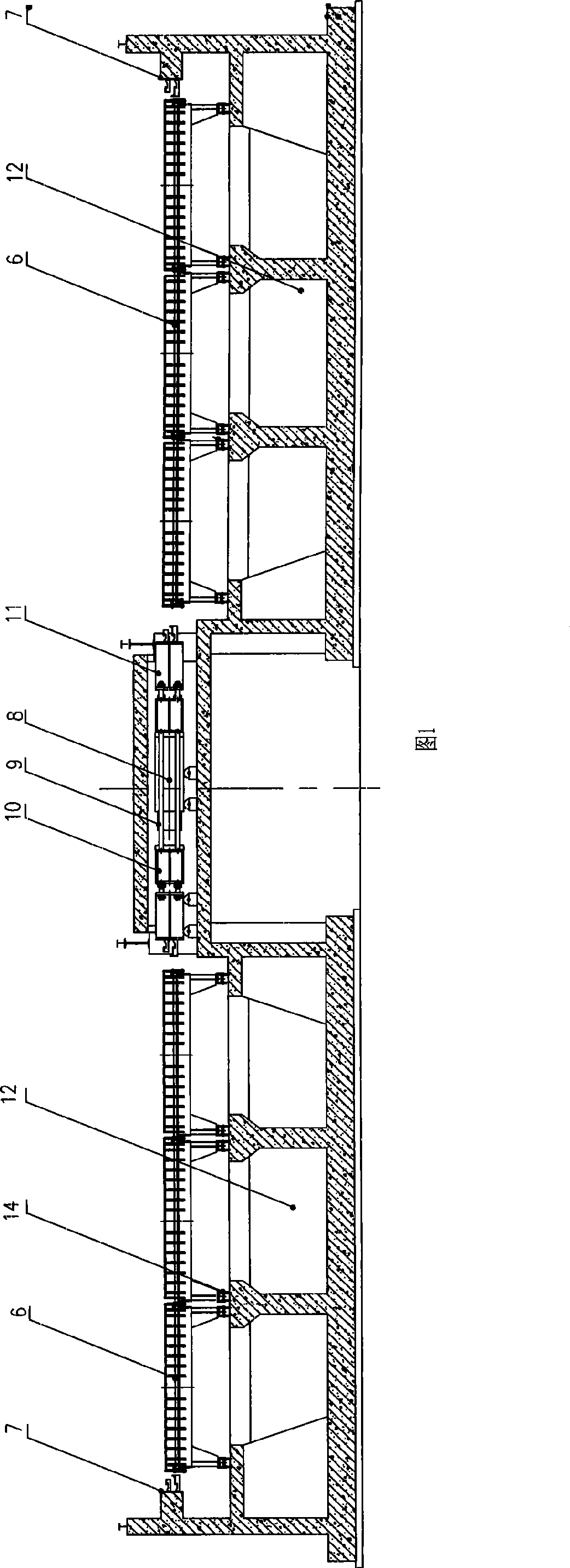

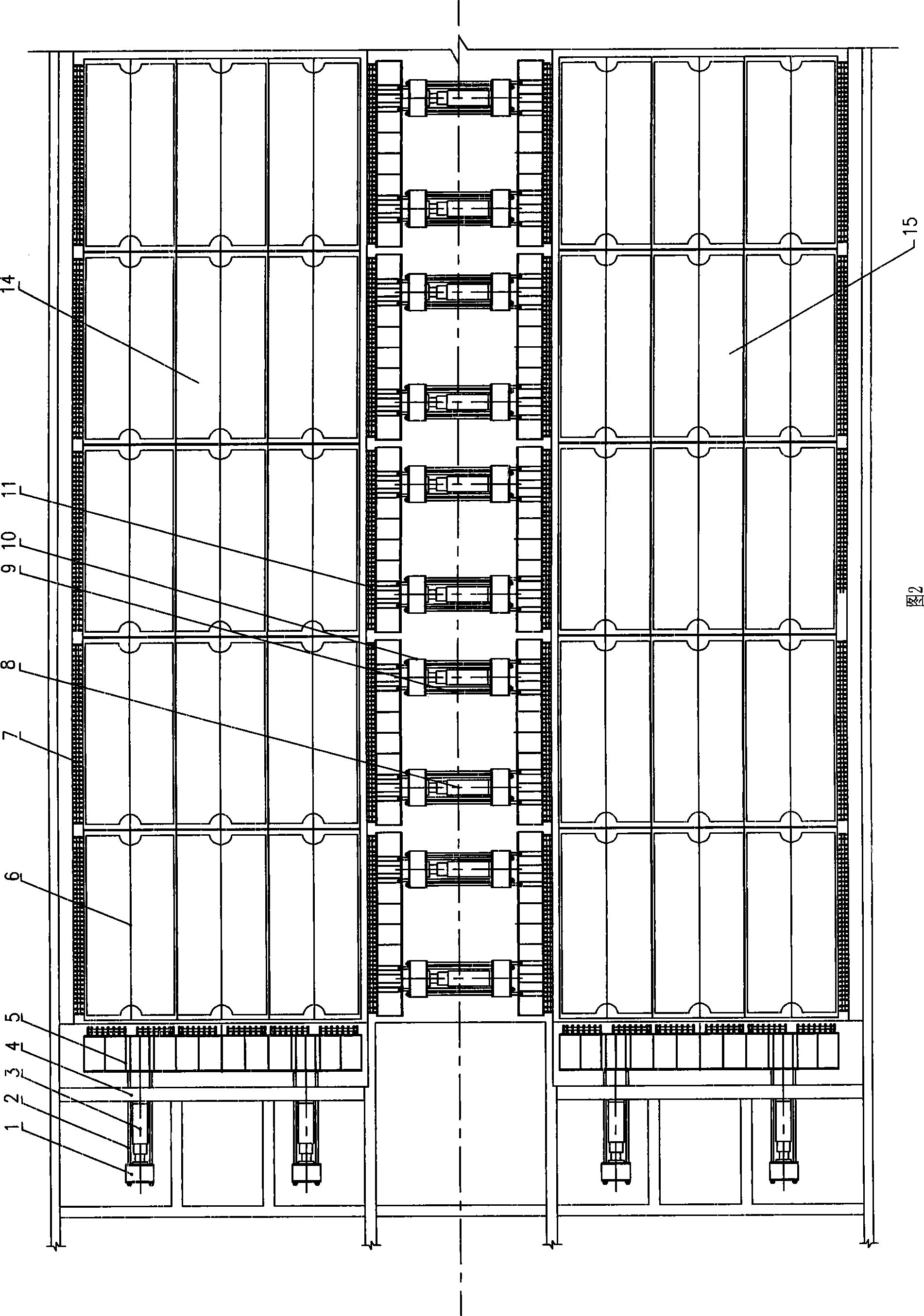

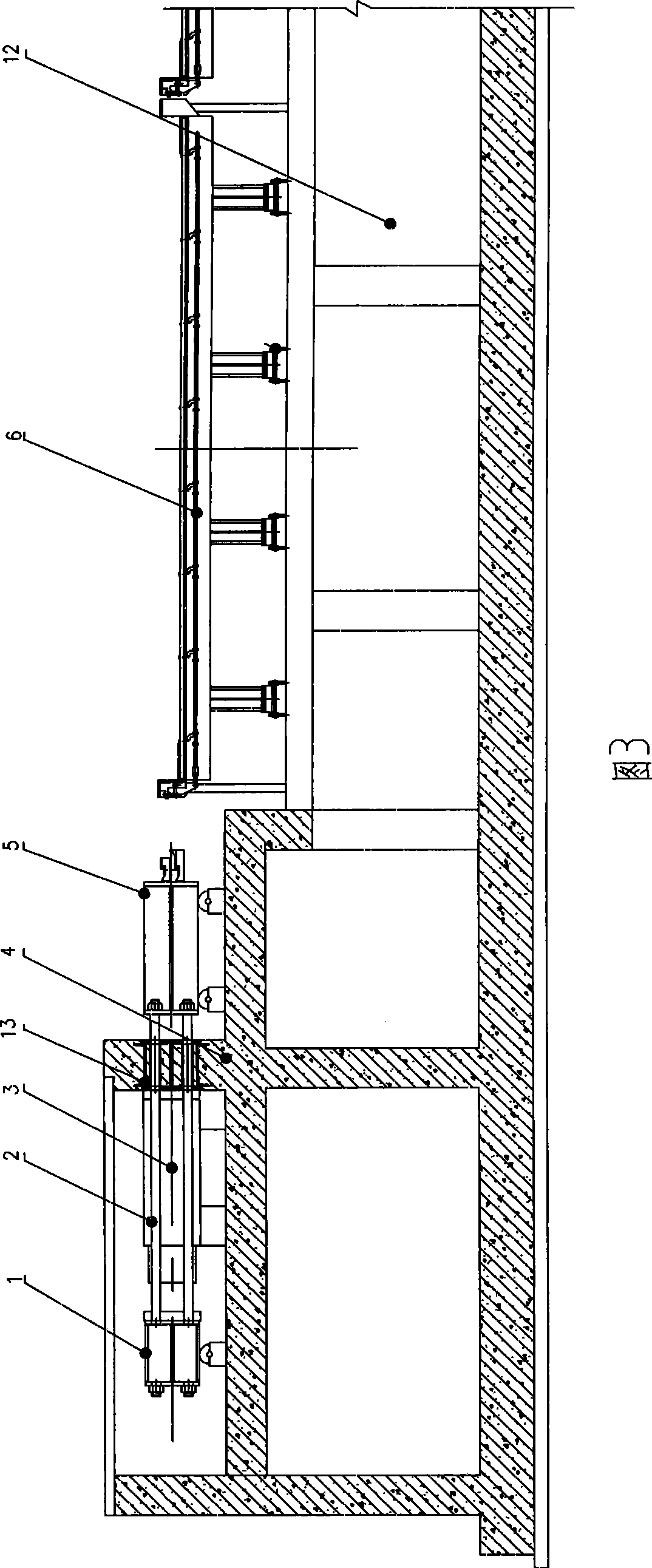

[0016] Embodiment: the two-way pretensioned track slab long-face pedestal production line shown in Figure 1--3 includes two symmetrically arranged production areas 14, 15, and steel models 6 for producing track slabs are arranged in the production areas 14, 15 The four sides of each production area 14 and 15 are respectively provided with transverse tension end beams 11 and longitudinal tension end beams 5 for fixing steel wires, and horizontal tension beams corresponding to the positions of the steel model 6 are set between the adjacent sides of the two production areas 14 and 15. As for the tensioning mechanism, a pair of longitudinal tensioning mechanisms corresponding to the positions of the steel model 6 are arranged on one or both sides of the two production areas 14 and 15.

[0017] Horizontal layout of the production line:

[0018] As shown in Figure 2 (due to the symmetry of the view, the symmetrical half of the view is omitted to facilitate a clearer reaction structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com