Bleeder valve for pressurised furnace

A relief valve and valve seat technology, applied in the field of relief valves, can solve problems such as reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

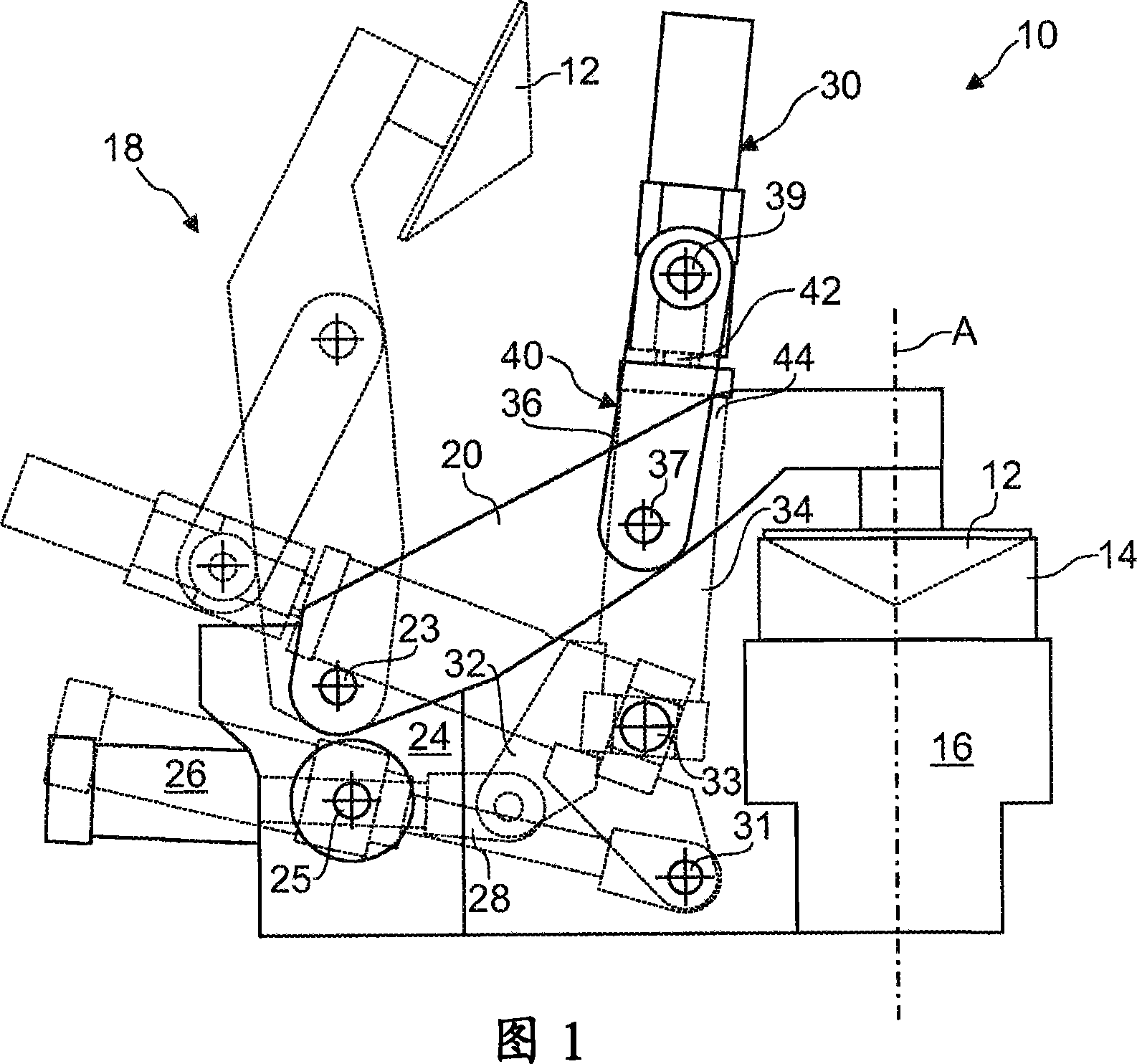

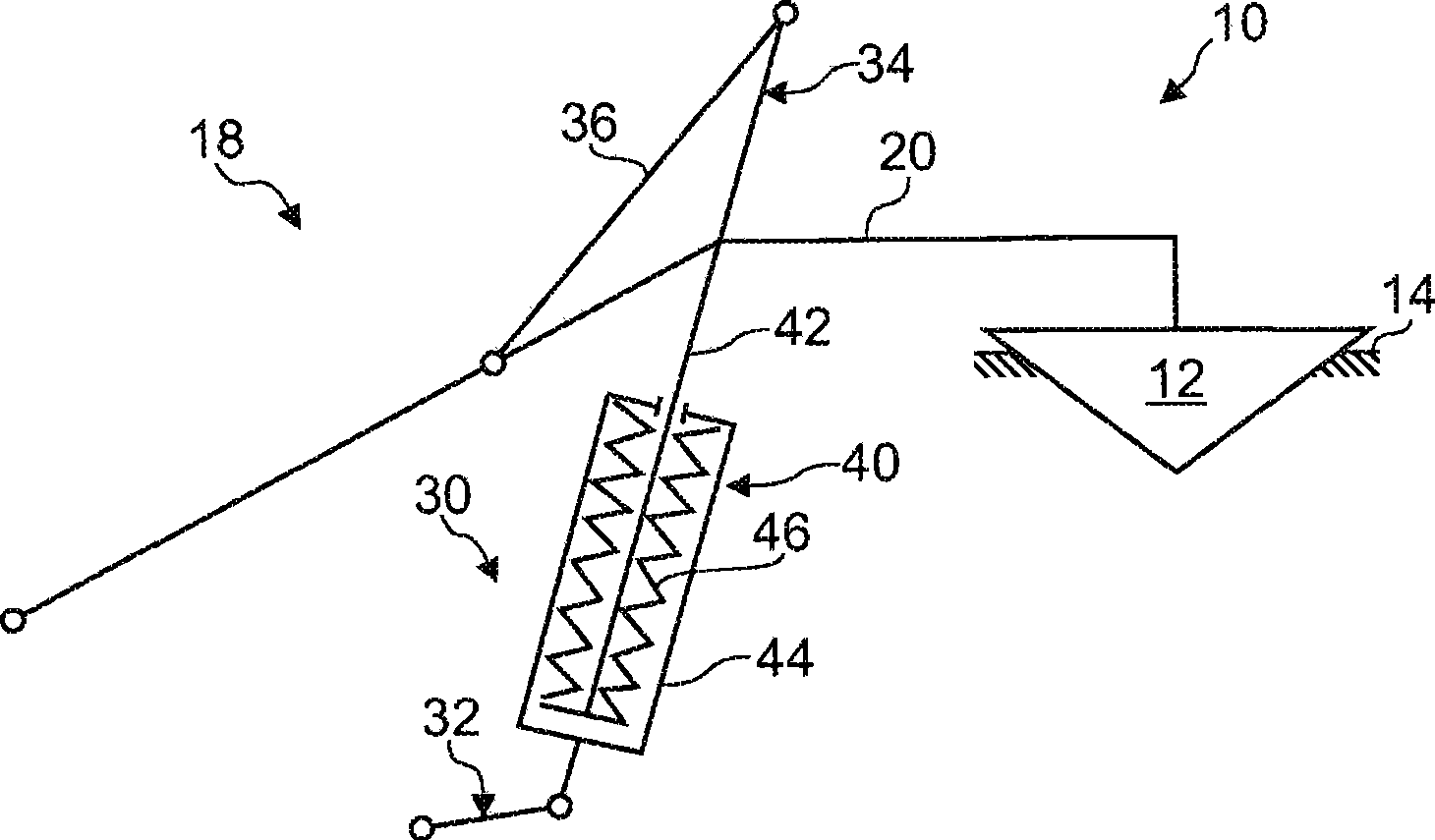

[0026] Figure 1 shows a relief valve (generally indicated by reference numeral 10) which is conventionally provided at the throat of a pressurized shaft furnace such as a blast furnace (not shown). The relief valve 10 includes a closure member 12 and a fixed valve seat 14 mounted coaxially on a discharge conduit 16 having a typical internal diameter of 400 mm to 1000 mm and communicating with the furnace throat. The relief valve 10 also includes an actuating mechanism (generally indicated by reference numeral 18) for switching between a closed position (shown in solid lines in FIG. 1 ) and an open position (shown in dashed lines in FIG. 1 ). Move the closing member 12 between.

[0027]The actuating mechanism 18 comprises a support arm 20 on a first end of which the closure member 12 is mounted by a ball and socket connection. A second end of the support arm 20 is pivotally connected to a fixed frame 24 by a shaft 23 for pivoting the shutter 12 between an open position and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com