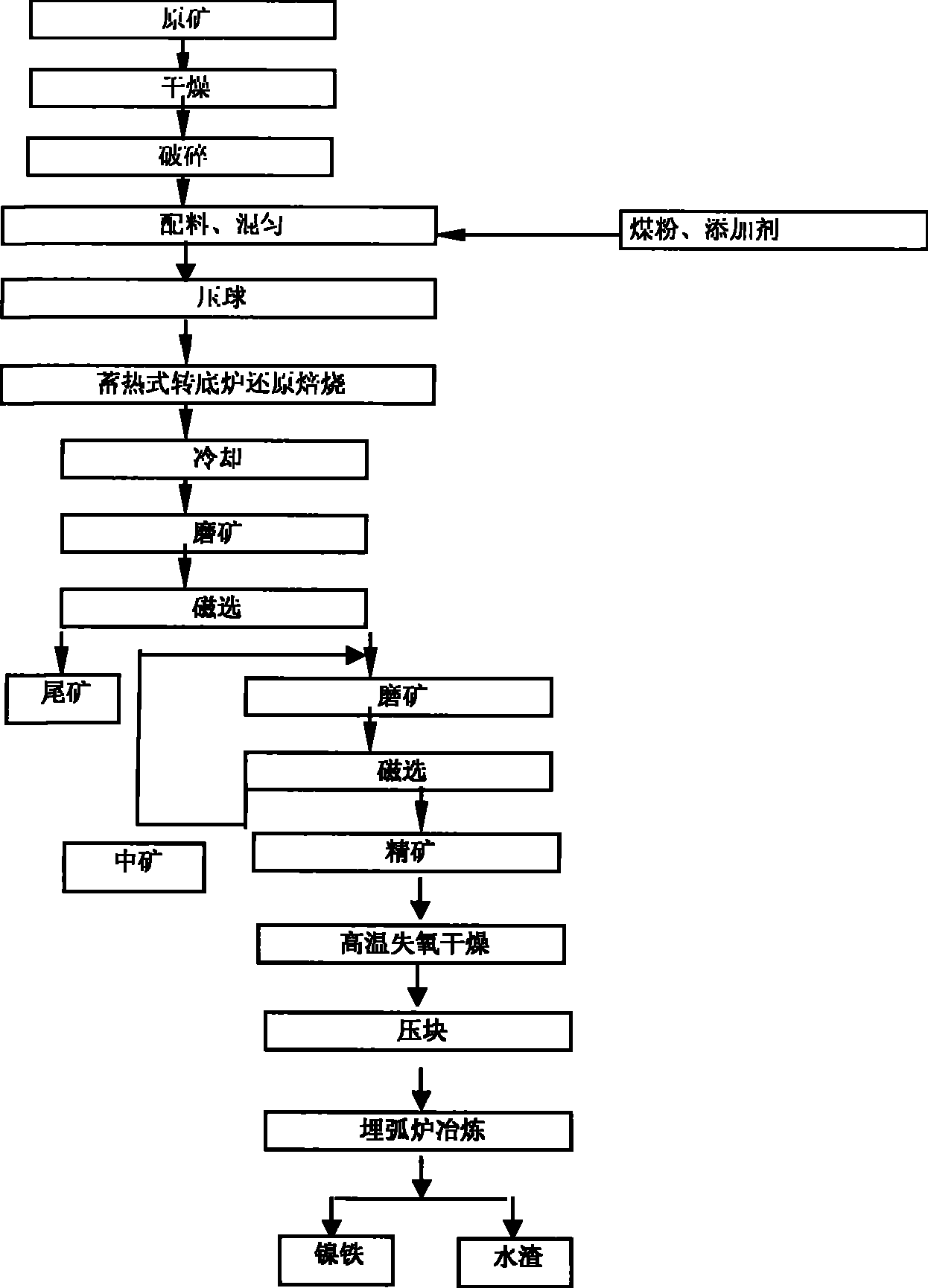

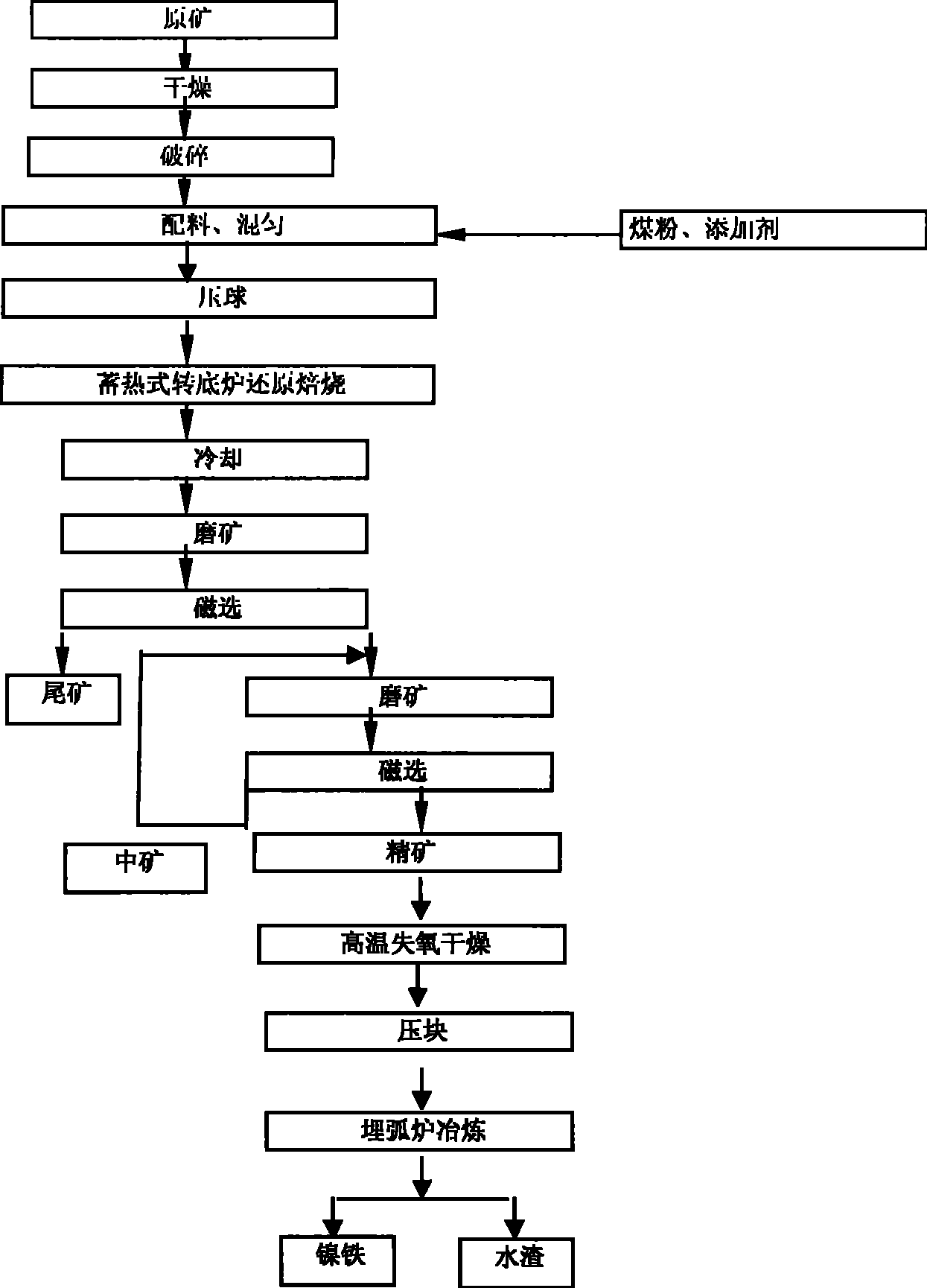

Heat accumulation type rotary hearth furnace-wet separation-buried arc furnace nickel ore smelting method

An electric furnace smelting and heat storage technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems of complex process, low efficiency, waste, etc., and achieve the effect of simple process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0030] Raw material preparation:

[0031] Coal: all kinds of bituminous coal and anthracite;

[0032] Laterite nickel ore: various grades of laterite nickel ore;

[0033] Binder: inorganic binder or organic binder.

[0034] The above-mentioned raw materials are proportioned according to the following parts by weight: coal: 5-10 parts; dust: 80-90 parts; binder: 2-5 parts.

[0035] Refining method:

[0036] Mix the above three raw materials evenly in proportion, make pellets, dry them and put them into the regenerative rotary hearth furnace. The calorific value of the fuel used in the rotary hearth furnace is 750kcal / Nm3~9000kcal / Nm3. Heating to 1100°C-1250°C in a rotary hearth furnace, keeping it for 10-40 minutes, and directly reducing to metallized pellets with a metallization rate of 70%-90%.

[0037] The metallized pellets at 800℃~1000℃ discharged from the rotary hearth furnace through the discharge device are directly sent into the water, and after cooling, they are g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com