Preparation of glass coating liquid having ultraviolet shielding function

A technology of external shielding and coating solution, which is applied in the field of preparation of glass coating solution, can solve the problem of high cost and achieve good light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention adopts a process method for preparing a glass coating solution with ultraviolet shielding function, and has the following process steps:

[0024] (1) Measure 41ml of ethyl orthosilicate and dissolve it in 32ml of ethanol.

[0025] (2) Measure 27ml of deionized water and adjust the pH to 2 with hydrochloric acid.

[0026] (3) Weigh 0.0856g of 2-methyl-5-nitroimidazole-1-ethanol, add it to the aqueous solution prepared in step (2), and heat to boiling until 2-methyl-5-nitroimidazole- Stop heating after 1-ethanol is dissolved, and add 1.7 g of glacial acetic acid after natural cooling.

[0027] (4) The ethyl orthosilicate ethanol solution prepared in step (1) is heated and stirred at 50° C., while the solution prepared in step (3) is slowly added dropwise.

[0028] (5) Heat and stir the mixture prepared in step (4) at 50°C for 2 hours.

[0029] (6) The sol prepared in step (5) is aged for 24-28 hours.

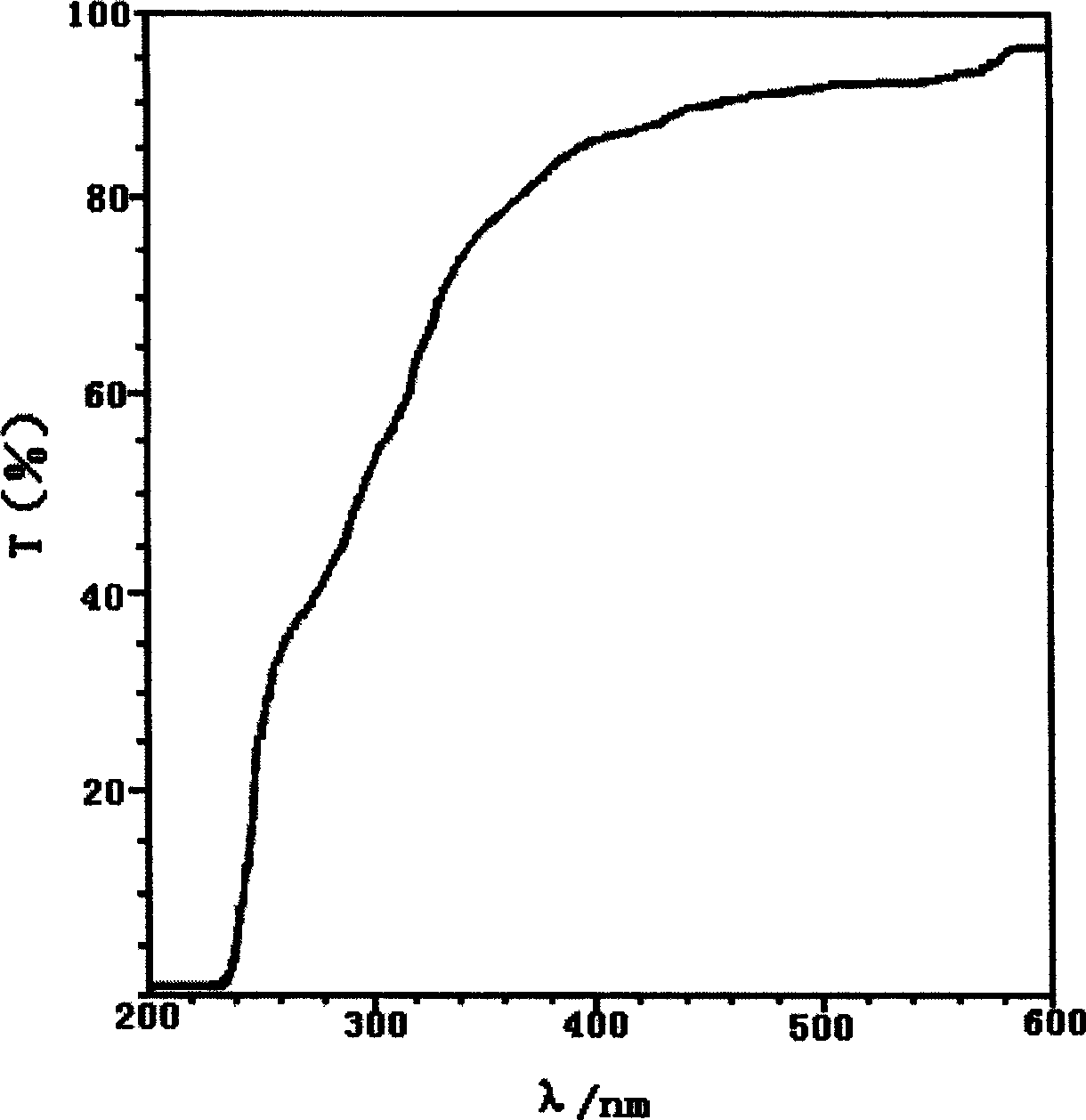

[0030] The ultraviolet transmission spectrum of the ...

Embodiment 2

[0034] The present invention adopts a process method for preparing a glass coating solution with ultraviolet shielding function, and has the following process steps:

[0035] (1) Measure 41ml of ethyl orthosilicate and dissolve it in 32ml of ethanol.

[0036] (2) Measure 27ml of deionized water and adjust the pH to 2 with hydrochloric acid.

[0037](3) Weigh 0.0428g of 2-methyl-5-nitroimidazole-1-ethanol, add it to the aqueous solution prepared in step (2), and heat to boiling until 2-methyl-5-nitroimidazole- Stop heating after the 1-ethanol is dissolved, and add 1.7 g of glacial acetic acid after cooling.

[0038] (4) The ethyl orthosilicate ethanol solution prepared in step (1) is heated and stirred at 50° C., while the solution prepared in step (3) is slowly added dropwise.

[0039] (5) Heat and stir the mixture prepared in step (4) at 50°C for 2 hours.

[0040] (6) The sol prepared in step (5) is aged for 24-28 hours.

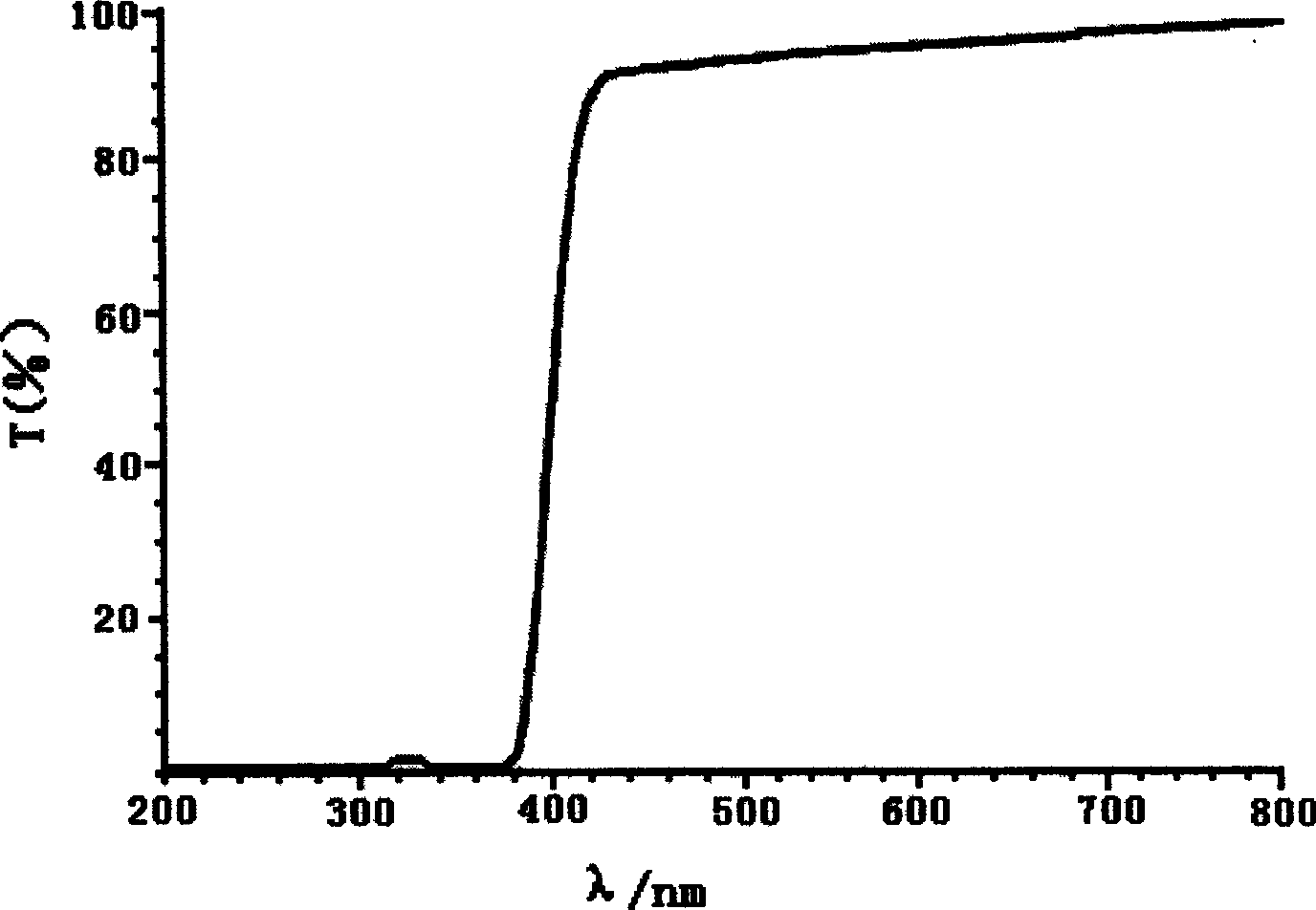

[0041] The ultraviolet transmission spectrum of the glass...

Embodiment 3

[0045] The present invention adopts a process method for preparing a glass coating solution with ultraviolet shielding function, and has the following process steps:

[0046] (1) Measure 41ml of ethyl orthosilicate and dissolve it in 32ml of ethanol.

[0047] (2) Measure 27ml of deionized water and adjust the pH to 2 with hydrochloric acid.

[0048] (3) Weigh 0.1284g of 2-methyl-5-nitroimidazole-1-ethanol, add it to the aqueous solution prepared in step (2), and heat to boiling until 2-methyl-5-nitroimidazole-1 -Stop heating after the ethanol is dissolved, and add 1.7 g of glacial acetic acid after cooling.

[0049] (4) The ethyl orthosilicate ethanol solution prepared in step (1) is heated and stirred at 50° C., while the solution prepared in step (3) is slowly added dropwise.

[0050] (5) Continue heating and stirring the mixed solution prepared in step (4) at 50°C for 2 hours.

[0051] (6) The solution prepared in step (5) is aged for 24 to 28 hours.

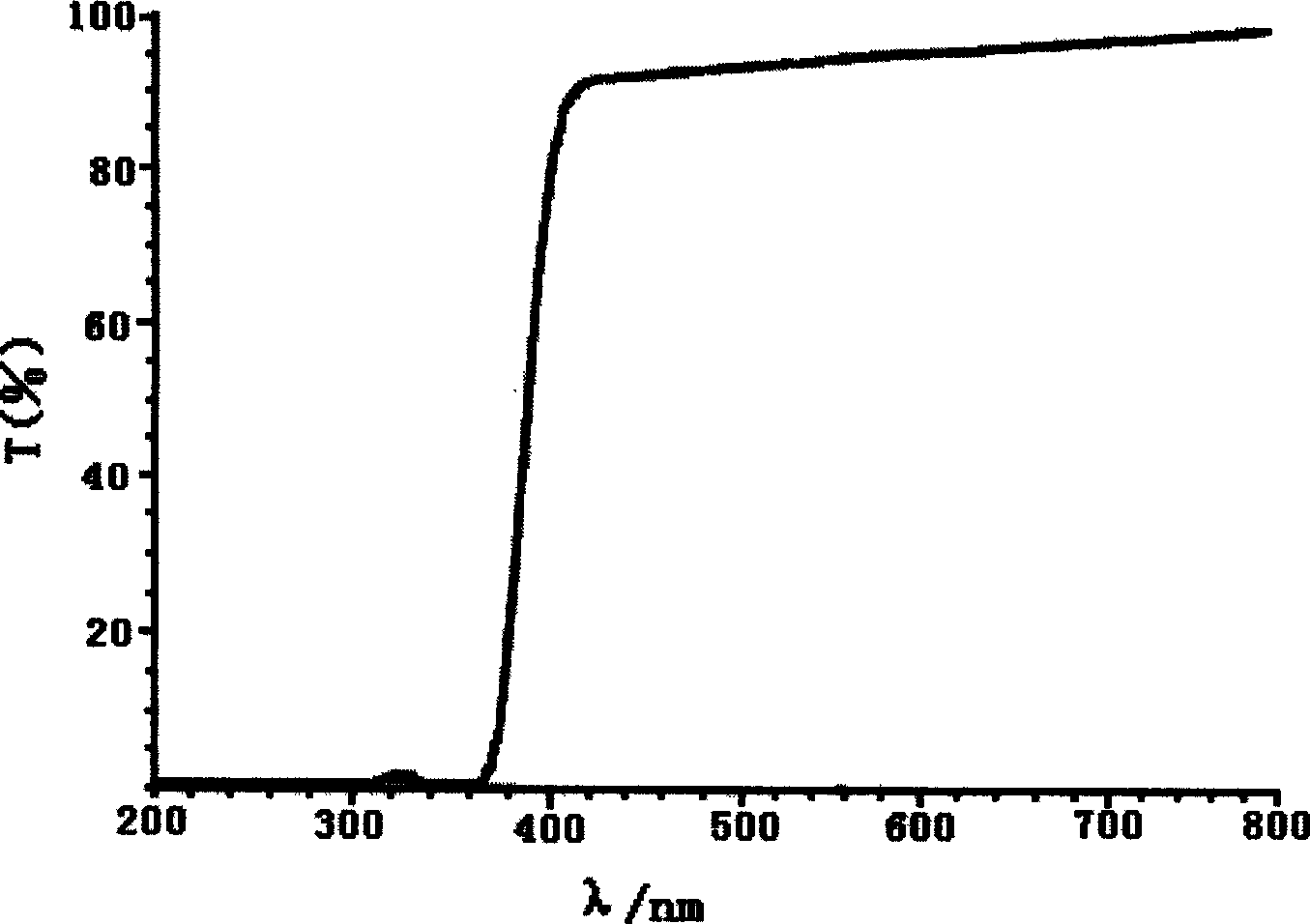

[0052] The ultraviolet tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com