5-shaft linkage numerical control bonding machine and welding process control method thereof

A five-axis linkage, welding machine technology, applied in digital control, welding equipment, welding equipment and other directions, can solve problems such as difficulty, affecting welding quality, impossible to complete, etc., to achieve improved machine tool space utilization, versatility and adaptability , the effect of optimizing the welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

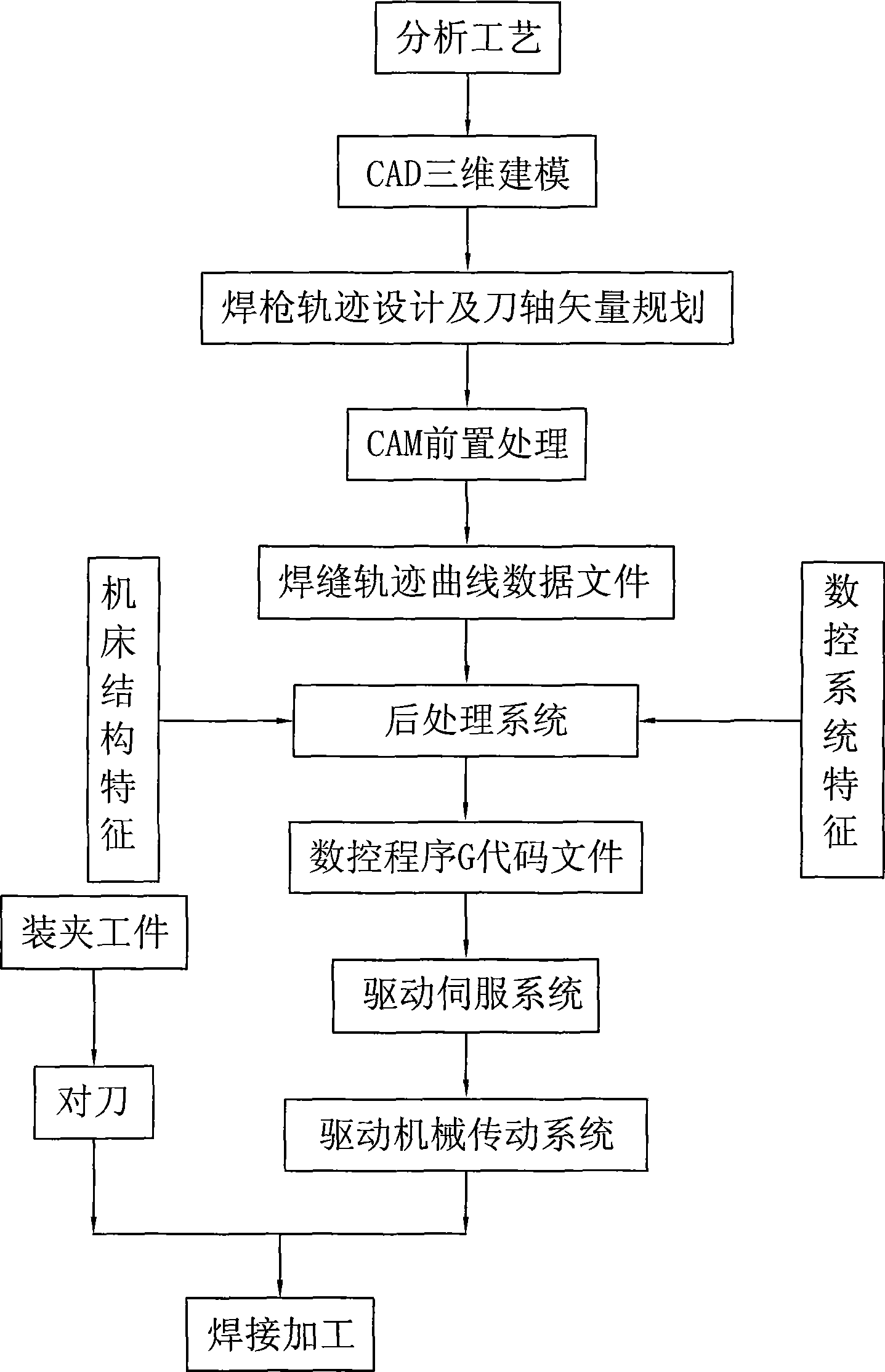

[0030] figure 1It is the welding process flow chart of the present invention. The five-axis linkage CNC welding machine described in the present invention includes a control system, a servo system, a detection system and a machine tool drive system. When a certain workpiece needs to be welded, it is necessary to use CAD / CAM The software performs operations such as modeling of the welding workpiece, planning of the welding process, design of the motion process, and definition of the process flow to output the weld trajectory data file of the workpiece, and then input the weld trajectory data file into the control system. The control system is used for calculation, management and control of CNC machine tools, including post-processing software and CNC system. The post-processing system reads the welding seam trajectory data file and applies s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com