Method for preparing carbon aerogel desulfurizing agent

A technology of carbon aerogel and desulfurizer, which is applied in the direction of chemical instruments and methods, selection of absorbent solid gas purification, and other chemical processes, which can solve the problems of low efficiency, reduced specific surface area and pore volume, and undiscovered question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

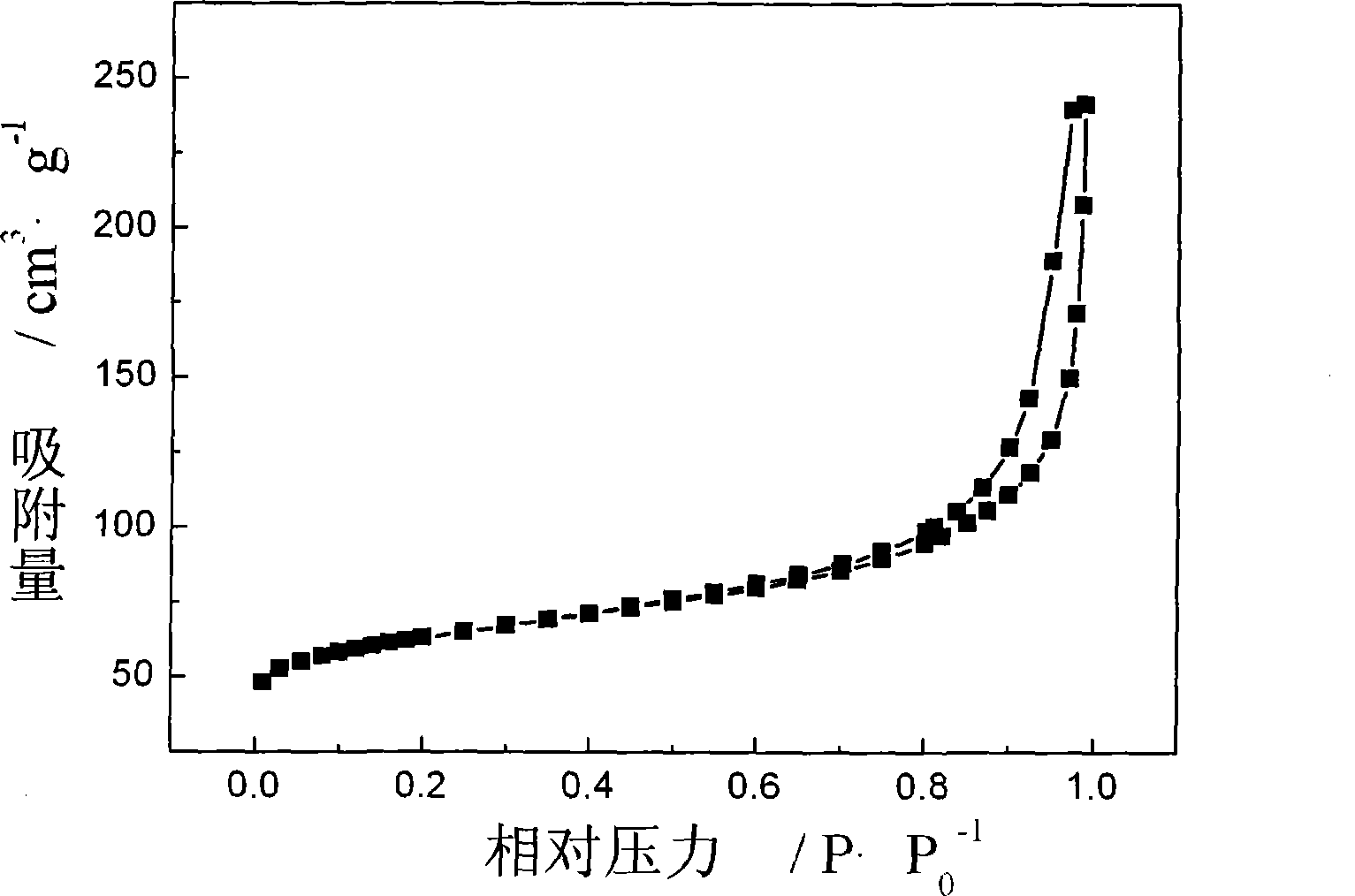

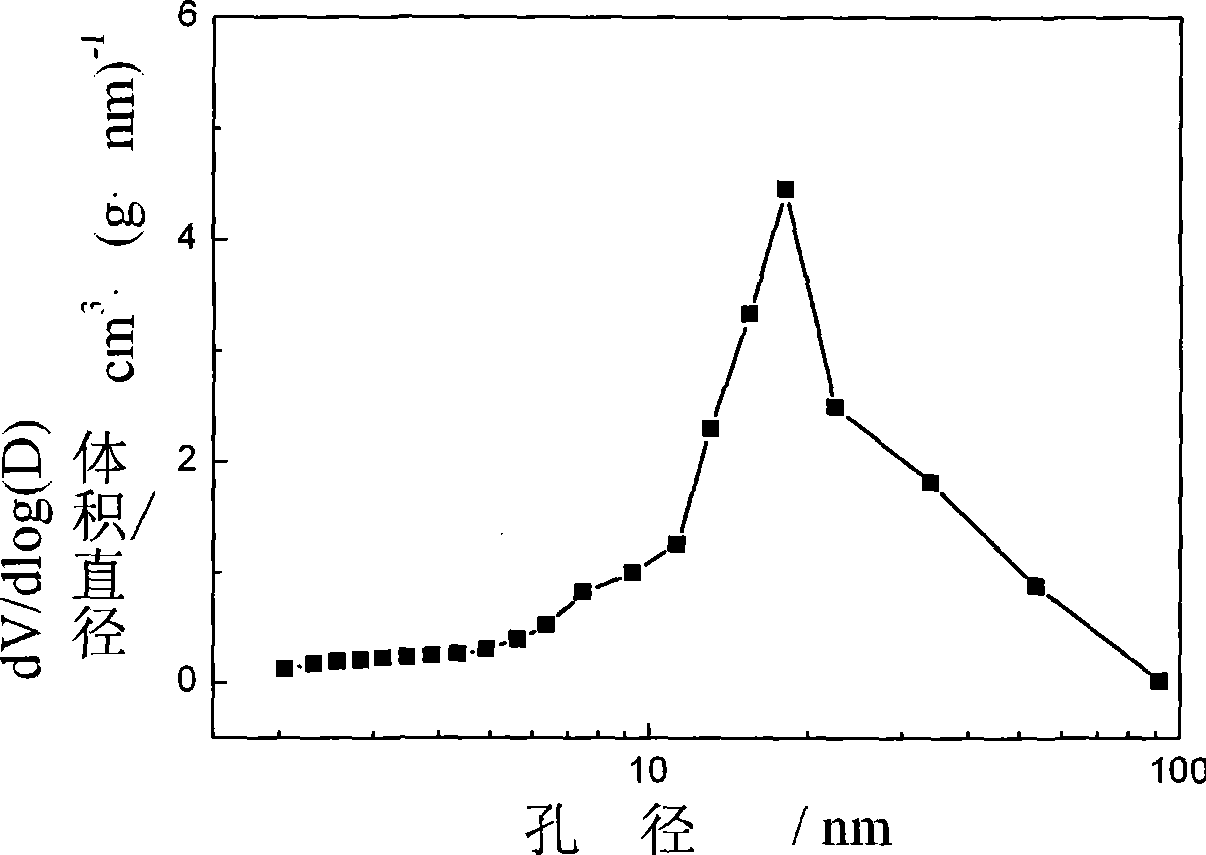

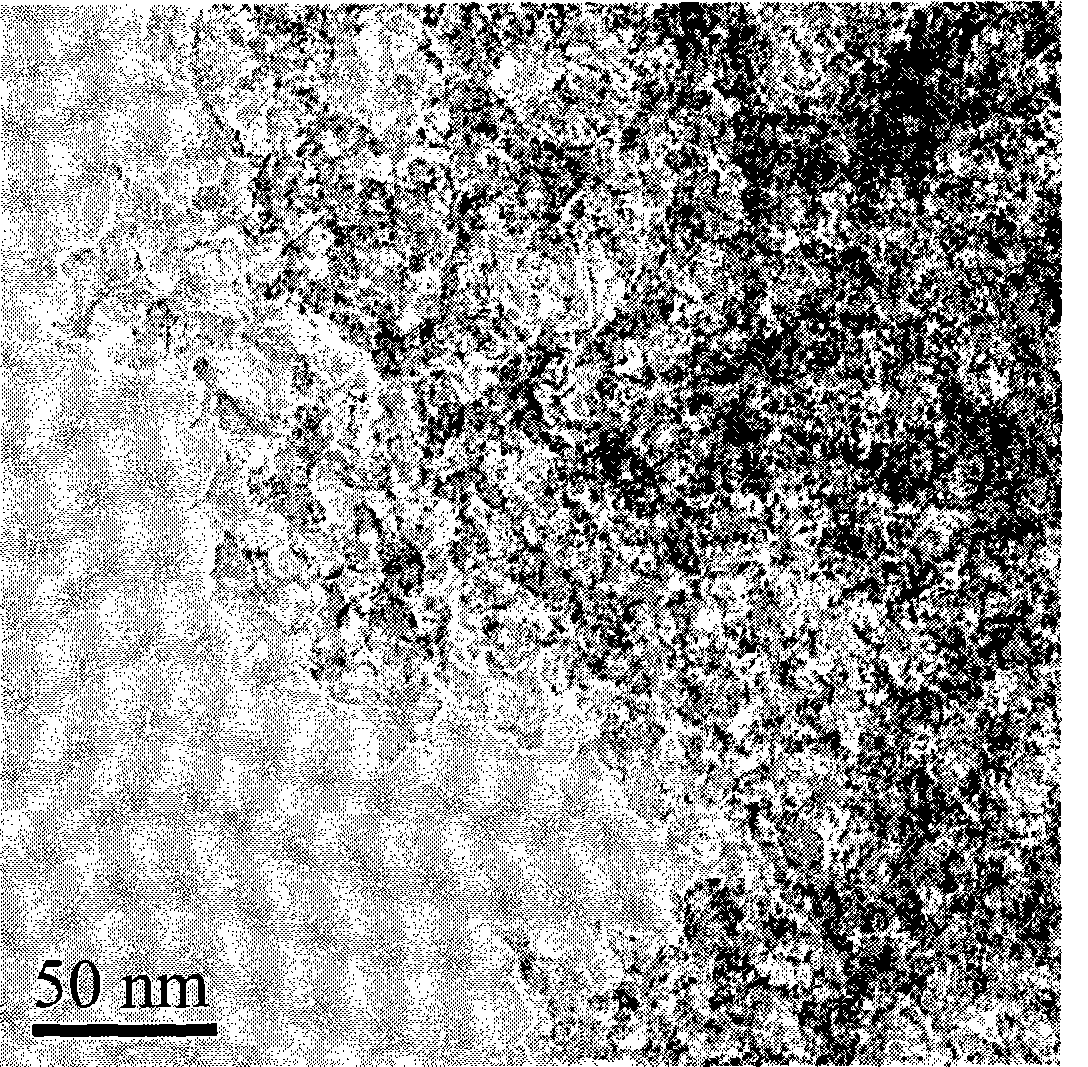

[0027] Phenol, formaldehyde, melamine, and commercial grade silica sol were mixed in a molar ratio of 1:2:0.4:4 to prepare a precursor solution, with a solid content of 40g / 100ml. Add 0.1mol / L NaOH to adjust the pH value to 9, carry out sol-gel reaction at 85°C, and continue aging for 4 days to obtain a composite hydrogel. Replace with absolute ethanol, and then dry in a mixed solution of absolute ethanol and petroleum ether at 250°C and 10MPa in a supercritical state for 4h. Then, under the protection of inert gas, it was carbonized at 800°C for 3h. Then soak it in HF acid solution to remove the inorganic template agent, adjust its pH value to neutral with deionized water, and dry under normal pressure to obtain carbon airgel. Finally, the carbon airgel was mixed with 8% Na 2 CO 3 The solution was impregnated with an equal volume, and dried at 130°C for 24 hours to obtain a carbon airgel desulfurizer. Its BET specific surface area is 650m 2 / g, the pore volume is 2.3cm ...

Embodiment 2

[0029] Phenol, formaldehyde, melamine, and commercial grade silica sol were mixed in a molar ratio of 1:2:0.8:4 to prepare a precursor solution, with a solid content of 40g / 100ml. Add 0.1mol / L NaOH to adjust the pH value to 9, carry out sol-gel reaction at 85°C, and continue aging for 4 days to obtain a composite hydrogel. Replace with absolute ethanol, and then dry in a mixed solution of absolute ethanol and petroleum ether at 250°C and 10MPa in a supercritical state for 4h. Then, under the protection of inert gas, it was carbonized at 800°C for 3h. Then soak it in HF acid solution to remove the inorganic template agent, adjust its pH value to neutral with deionized water, and dry under normal pressure to obtain carbon airgel. Finally, the carbon airgel was mixed with 8% Na 2 CO 3 The solution was impregnated with an equal volume, and dried at 130°C for 24 hours to obtain a carbon airgel desulfurizer. Its BET specific surface area is 756m 2 / g, the pore volume is 3.1cm ...

Embodiment 3

[0031]Phenol, formaldehyde, melamine, and commercial grade silica sol were mixed in a molar ratio of 1:2:1.2:4 to prepare a precursor solution, with a solid content of 40g / 100ml. Add 0.1mol / L NaOH to adjust the pH value to 9, carry out sol-gel reaction at 85°C, and continue aging for 4 days to obtain a composite hydrogel. Replace with absolute ethanol, and then dry in a mixed solution of absolute ethanol and petroleum ether at 250°C and 10MPa in a supercritical state for 4h. Then, under the protection of inert gas, it was carbonized at 800°C for 3h. Then soak it in HF acid solution to remove the inorganic template agent, adjust its pH value to neutral with deionized water, and dry under normal pressure to obtain carbon airgel. Finally, the carbon airgel was mixed with 8% Na 2 CO 3 The solution was impregnated with an equal volume, and dried at 130°C for 24 hours to obtain a carbon airgel desulfurizer. Its BET specific surface area is 844m 2 / g, the pore volume is 3.9cm 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com