Right and left ear terminal grain-holding claw conveying chain guide device

A technology of conveying chain and guide rail device, applied in cutters, agricultural machinery and implements, applications, etc., can solve problems such as troublesome use, shortened service life, easy rusting of bolts, etc., to improve the efficiency of disassembly and assembly, and ensure service life. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

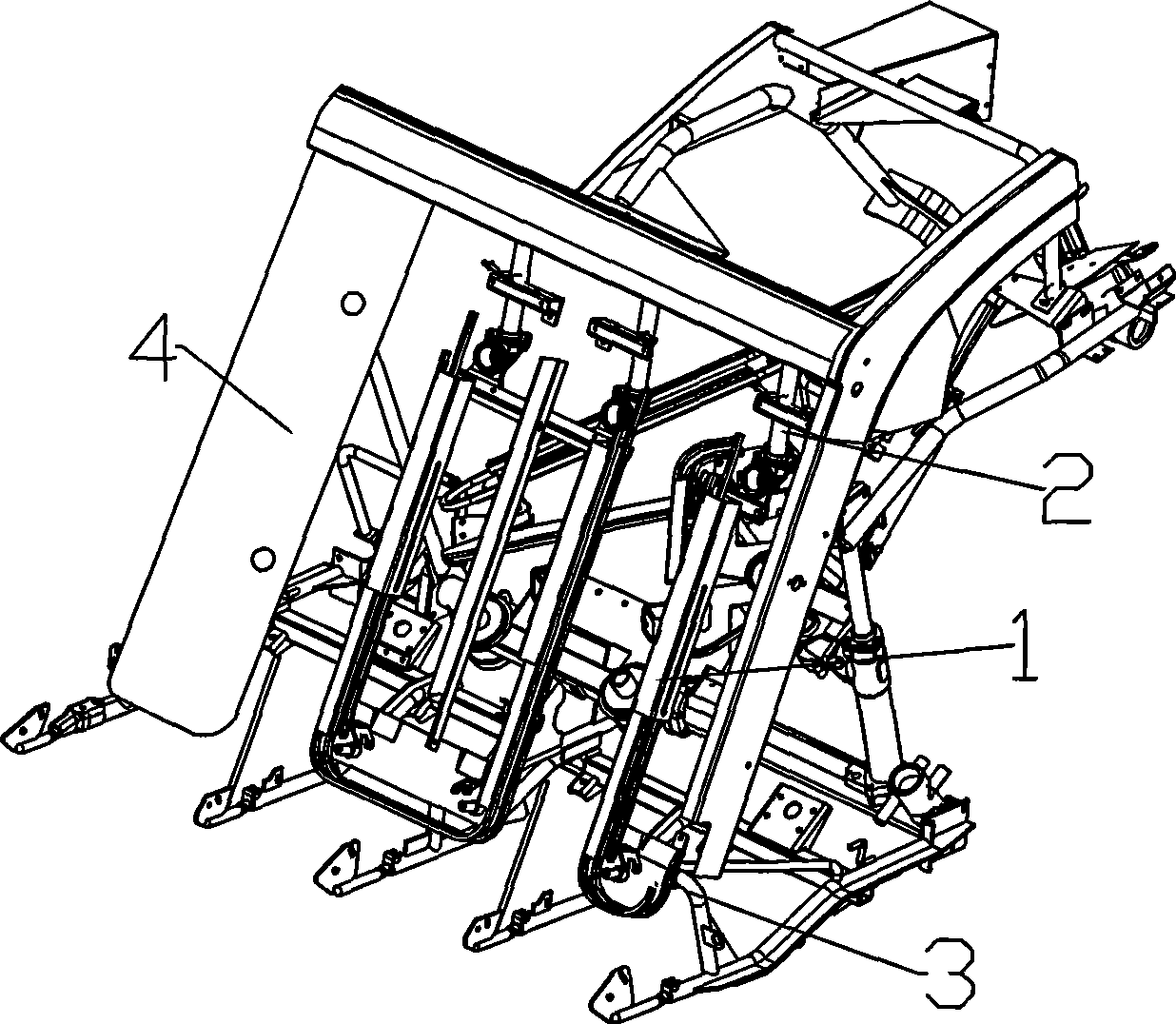

[0019] Below in conjunction with the accompanying drawings, the present invention will further describe the conveyor chain guide rail device for the left and right fringe ends:

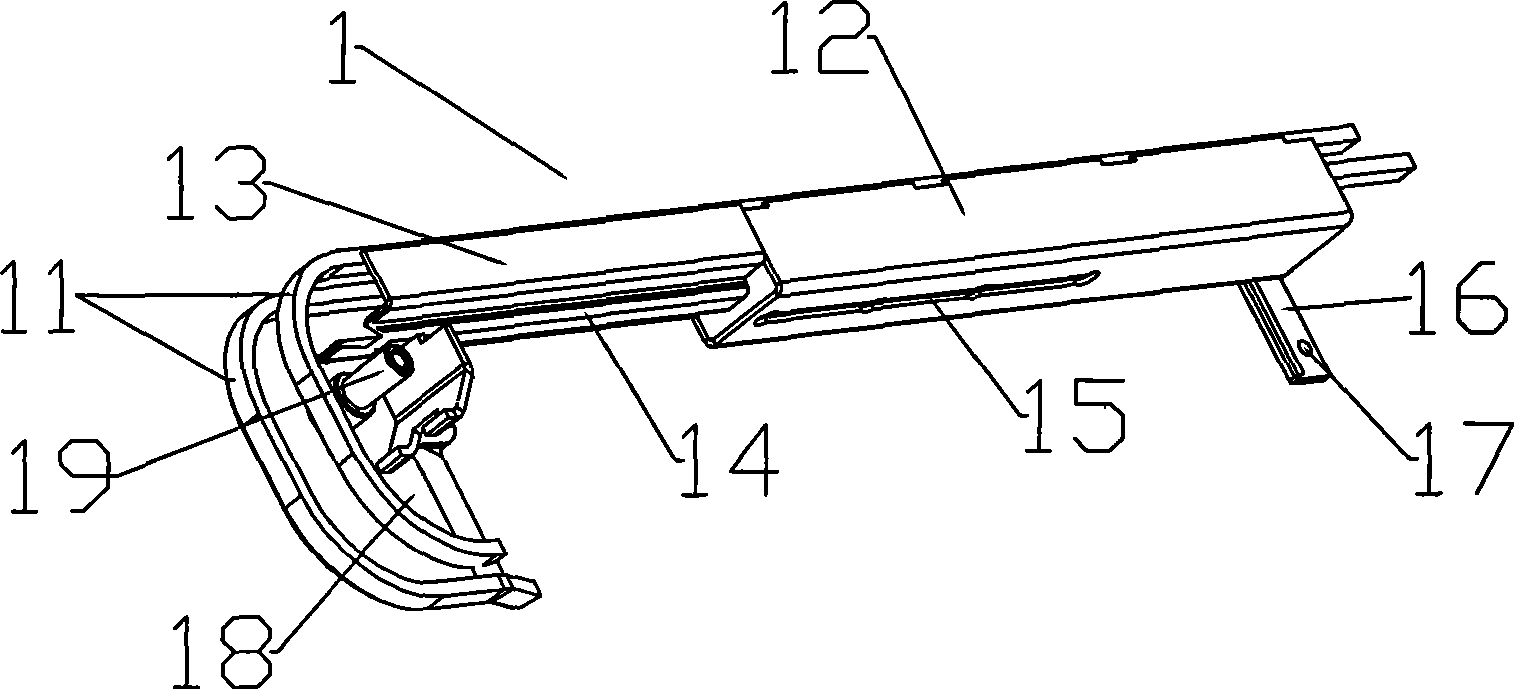

[0020] Such as figure 1 As shown, the conveying device of the present invention includes a conveying guide rail 1 arranged on the left and right sides of the front of the harvester and inclined backward, and the conveying guide rail 1 includes two square rod metal bodies bent into an "L" shape. 11. Two "L"-shaped solid square rod metal bodies 11 are stacked at intervals. A metal plate bent into a groove is fixed on the inclined section of the two square rod metal bodies. The opening of the groove faces the two "L" after stacking. Type solid square bar metal body, the metal plate bent into grooves is welded and fixed on the square bar metal body 11. Groove is divided into upper and lower two parts, and the bottom of upper part groove 12 is provided with the bar-shaped through groove 15 that is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com