Novel rubber and thermoplastic multi-component systems rubber and thermoplastic composite moulded pieces made therefrom method for production and use thereof

A thermoplastic, multi-component technology for excellent sealing and/or vibration damping in multi-component systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

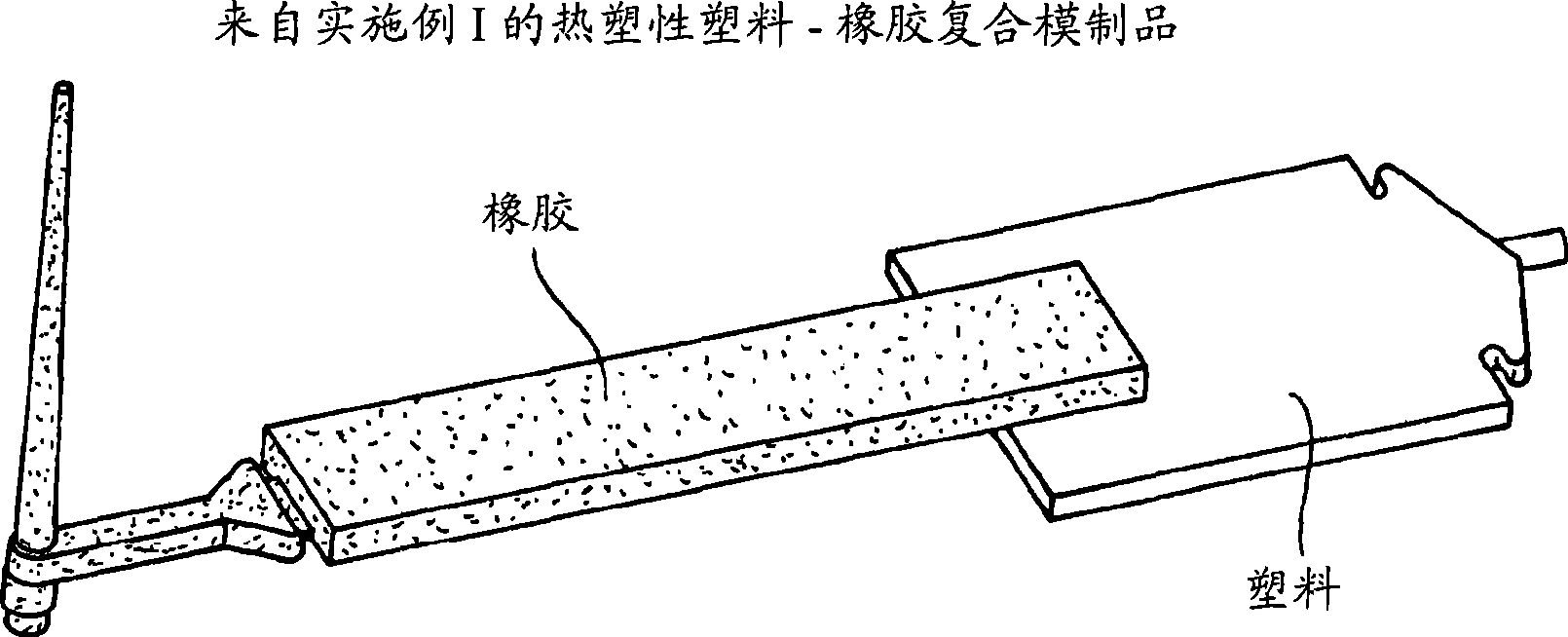

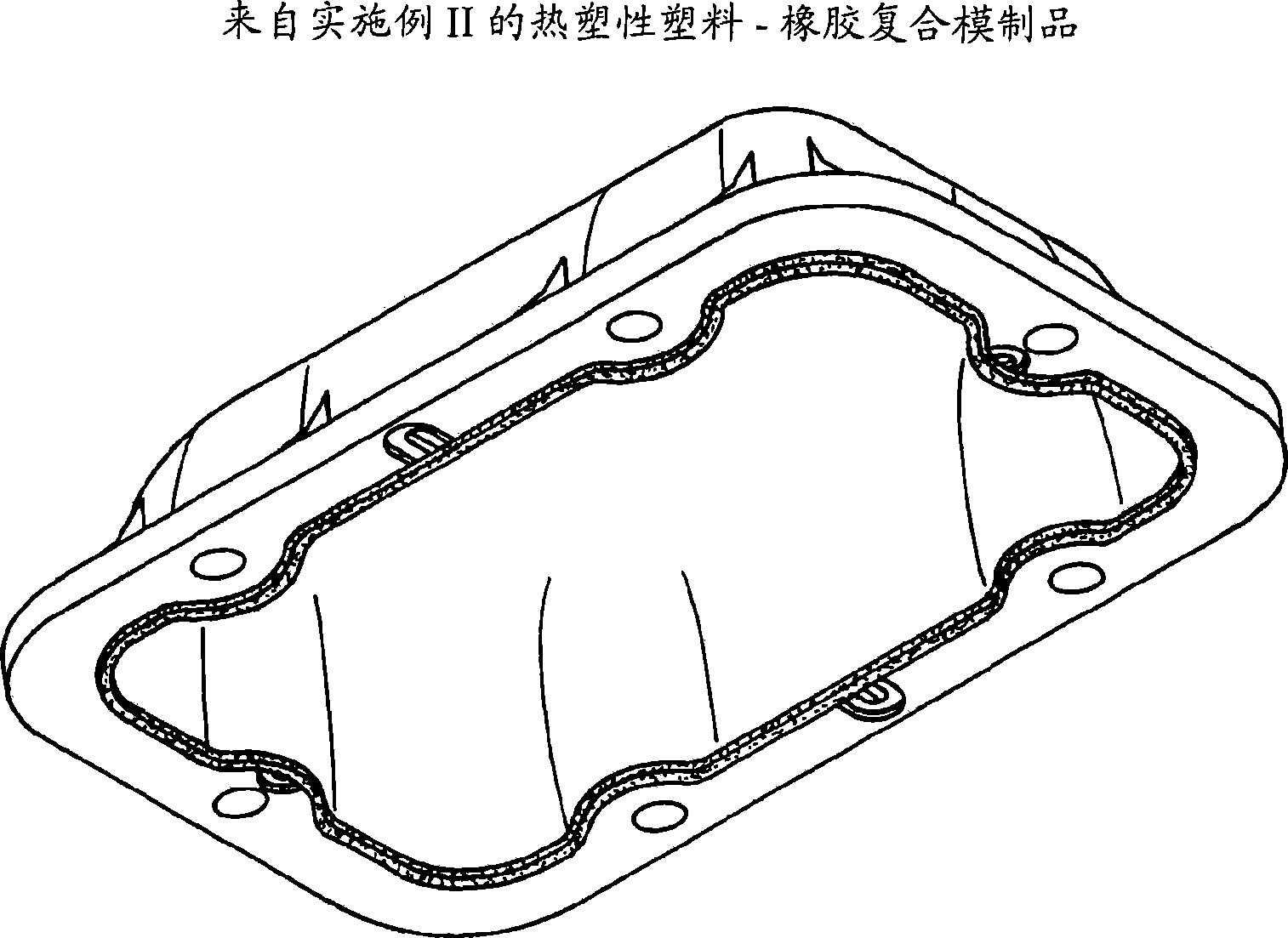

Examples

example 1-37

[0181] Preparation and Study of Composite Elastomer Material (Rubber Component 2)

[0182] The following substances were used in the examples:

[0183] 18D Prills zinc salts of 4- and 5-methyl-2-mercaptobenzimidazoles have a density at 25°C of

[0184] 1.25g / cm 3 ;Lanxess Deutschland GmbH

[0185] EPG 5450 Ethylene-propylene-ENB terpolymer (EPDM) with 52% ethylene

[0186] And the Mooney viscosity (ML1+4@125°C) is 46; Lanxess

[0187] Deutschland GmbH

[0188] EPT 2450 ethylene-propylene-ENB terpolymer (EPDM) with an ethylene content of 59% and

[0189] And the Mooney viscosity (ML1+8@100℃) is 35; Lanxess

[0190] Deutschland GmbH

[0191] N 550 carbon black; Fast Extrusion Furnace (FEF) from Degussa AG

[0192] No 7 Triallyl Isocyanurate from DuPont

[0193] TM 8-10ST Stabilized C 8 -C 19 Linear alcohol trimellitate, density 0.97...

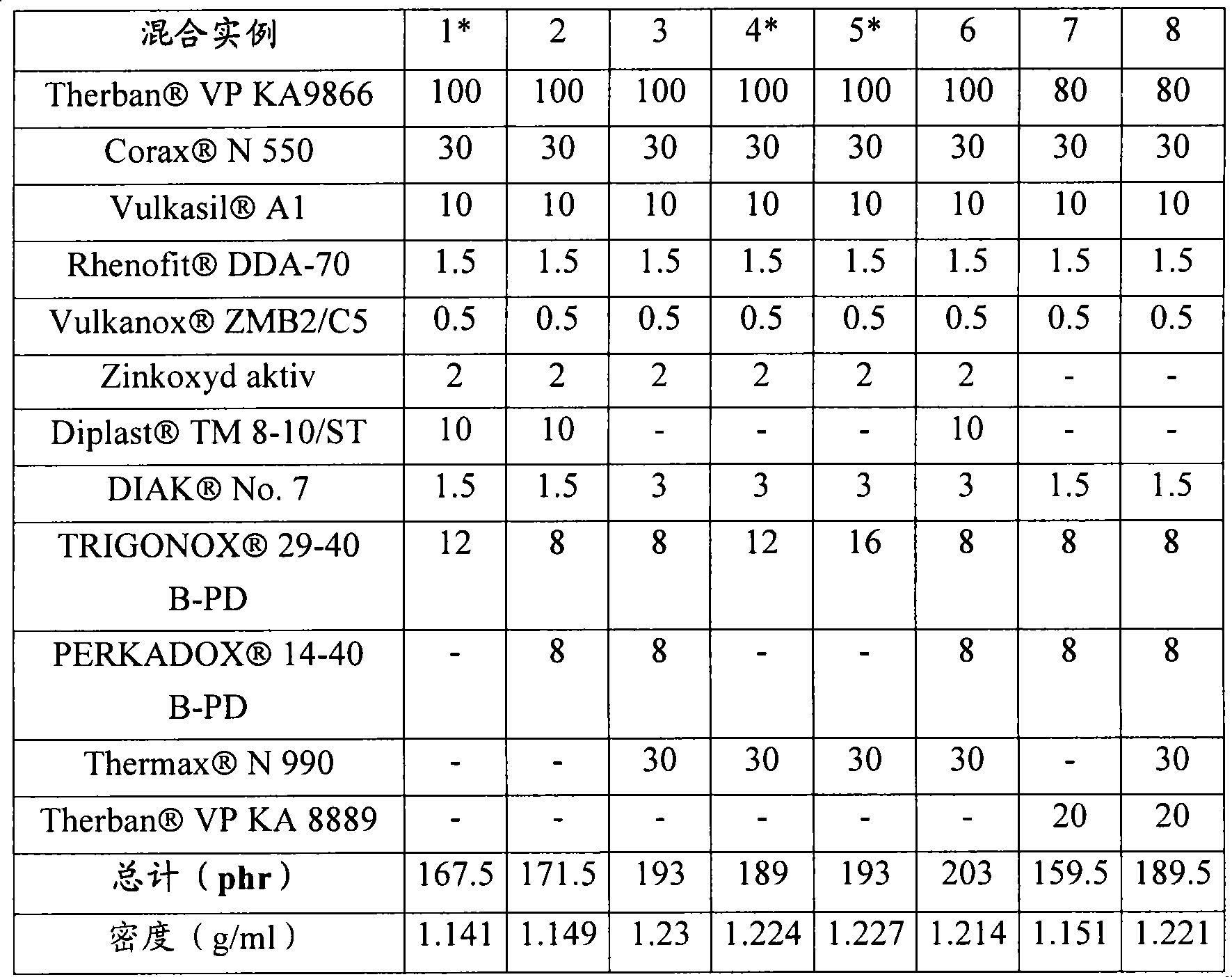

example 1-8

[0242] Rubber compounds marked with "*"1 * 、4 * and 5 * having a composition whose combined thermoplastic components would produce a comparative example for the purposes of the present invention, whereas, in contrast, Mixtures 2, 3, 6, 7 and 8 had compositions whose combined thermoplastic components would produce a comparative example useful for the purposes of the present invention Create instances of purpose.

[0243] Table 2: Composition of Elastomer Blends 1-8:

[0244]

[0245] The properties described in Table 3 were determined for mixtures 1-8.

[0246] Mooney viscosity is determined according to DIN D 1646 at 100°C.

[0247] Table 3: Determination of Mooney viscosities of mixtures 1-8 on test specimens according to DIN D 1646

[0248] example 1 * 2 3 4 * 5 * 6 7 8 ML1+4@100℃ MU 47 46 75 79 77 54 73 88

[0249] The curing behavior of mixtures 1-8 was then investigated (Table 4) using a Monsanto MDR 2000 rheometer with a tes...

example 9-19

[0267] Mixtures 9-19 having the compositions described in Table 7 were prepared by the process described. Compounds marked with * in Table 7 are examples whose combination of thermoplastic components would yield comparative examples for the purposes of this application, while unmarked mixes have compositions whose appropriate combination of thermoplastic components would yield comparative examples for the purposes of this application. Example of the invention.

[0268] Table 7: Composition of Mixtures 9-19

[0269]

[0270] The Mooney viscosities (ML1+4@100°C) stated in Table 8 were determined according to DIN D 1646 for elastomer mixtures 9-19.

[0271] Table 8A: Mooney Viscosities of Elastomer Blends 9-19

[0272] example 9 * 10 * 11 * 12 * 13 * 14 15 16 17 18 19 ML1+4@100℃ 121 78 121 80 82 112 75 114 75 81 81

[0273] The curing behavior of mixtures 9-19 was then investigated using a Monsanto MDR 2000 rheometer at test tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com