Head driving device and head driving method for ink jet printer, and ink jet printer

A technology of inkjet printers and drive devices, which is applied in printing and other fields, and can solve problems such as excessive heat dissipation plates and inability to drive pulse output circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

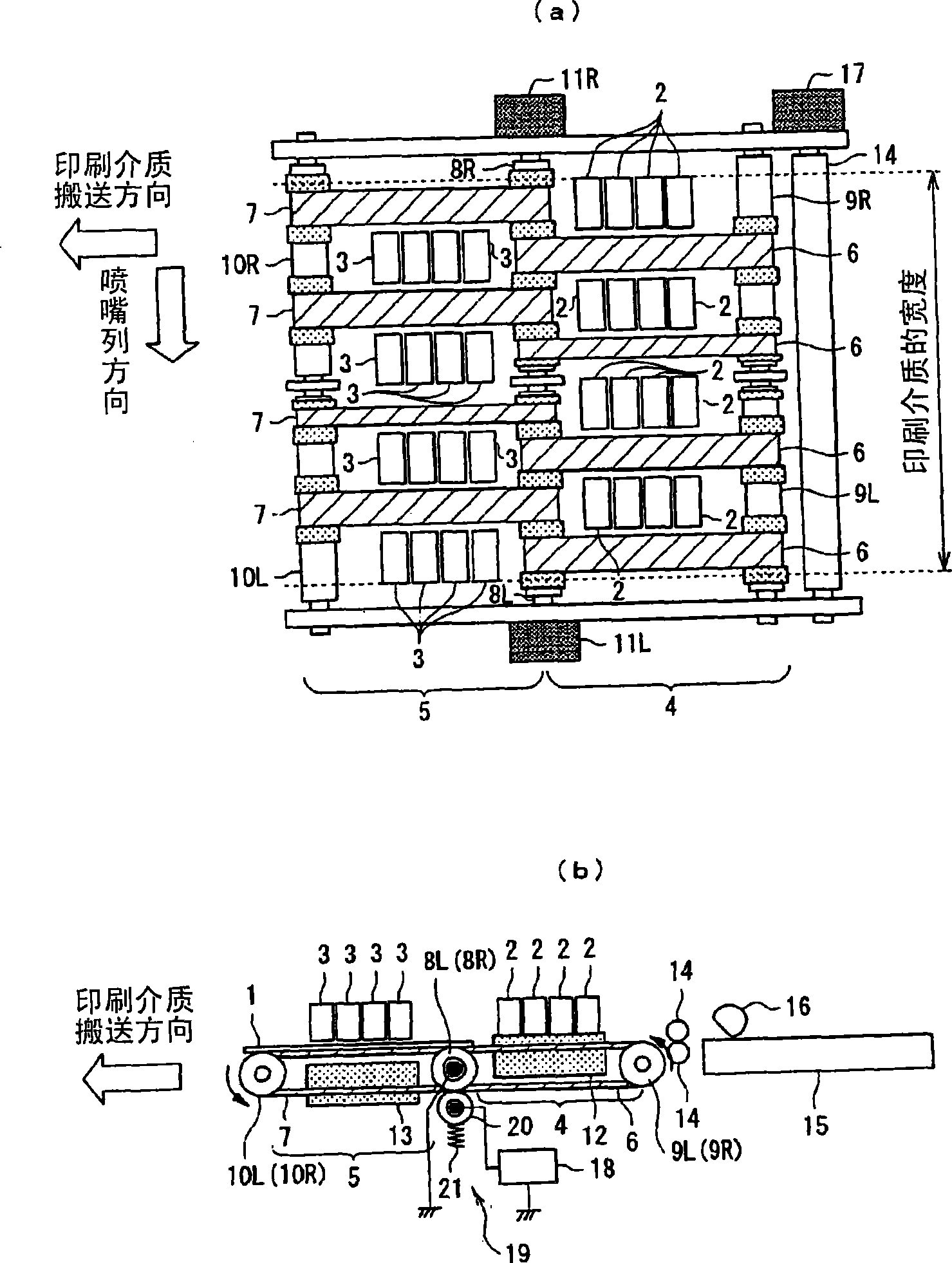

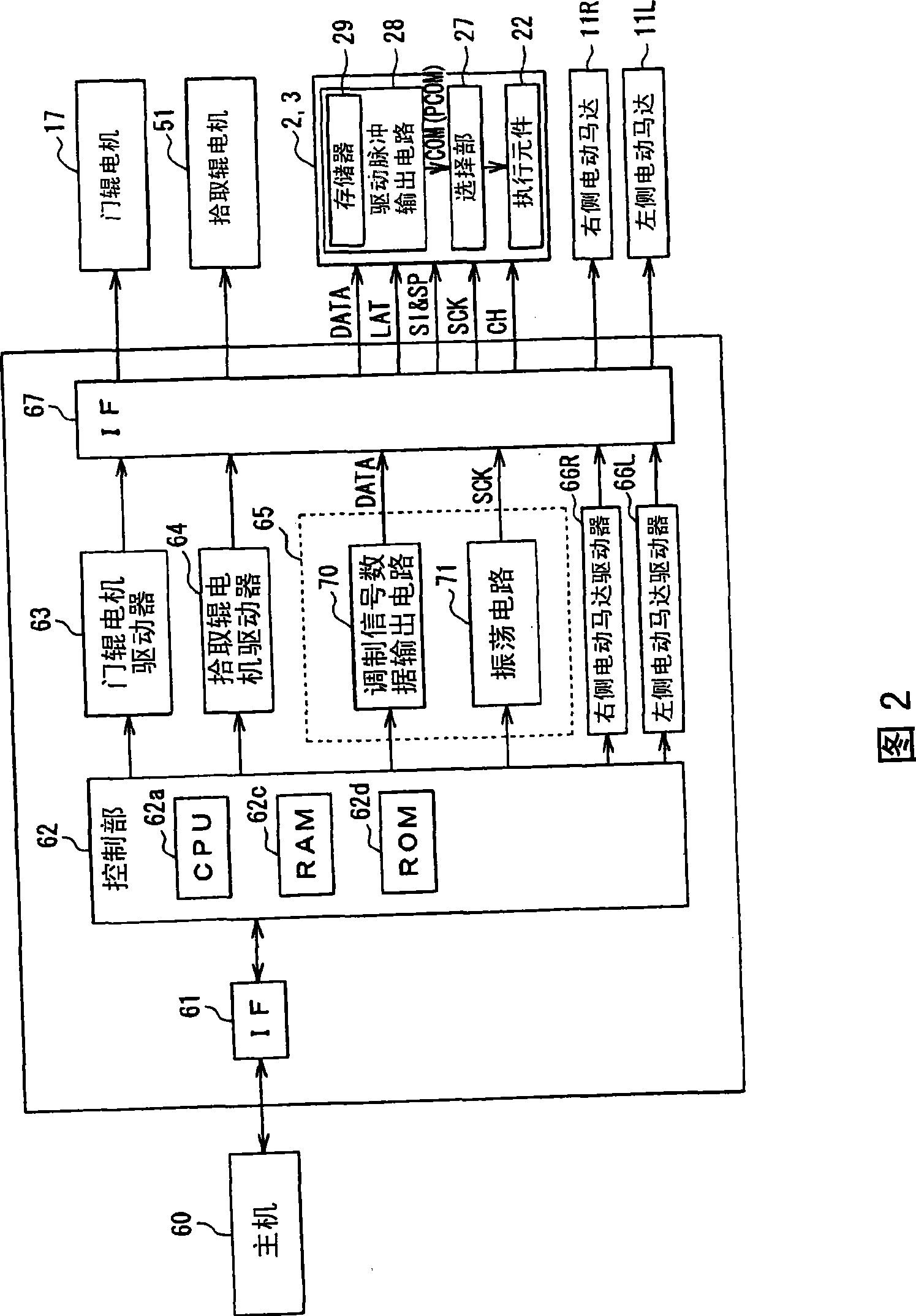

[0027] Next, a first embodiment of the inkjet printer of the present invention will be described with reference to the drawings.

[0028] figure 1 is a schematic configuration diagram of an inkjet printer according to this embodiment, figure 1 a is its top view, figure 1 b is the front view. figure 1 In the figure, the printing medium 1 is conveyed from the right side to the left side of the figure along the direction of the arrow in the figure, showing a line head type inkjet printer that prints on the printing area during its conveyance. However, the inkjet head of this embodiment is not installed at only one location, but is installed at two locations.

[0029] The symbol 2 in the figure is the first inkjet head that is arranged on the upstream side of the conveying direction of the printing medium 1, and the symbol 3 is the second inkjet head that is similarly arranged on the downstream side. The second conveyance part 5 is provided below the second inkjet head 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com