Method for preparing lithium ion battery anode material lithium iron phosphate

A technology for lithium iron phosphate and lithium ion batteries, which is applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc. It can solve the problems affecting the performance of positive electrode materials and batteries, the inability to guarantee the complete reaction, and the reduction in the capacity of lithium iron phosphate. problems, to achieve the effect of easy industrial production, low cost, and less consumption of reducing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take by weighing phosphoric acid and ferrous sulfate according to molar ratio P:Fe=1:1, in N 2In the atmosphere, dissolve phosphoric acid and ferrous sulfate in distilled water, adjust the pH value with hydrochloric acid to make it 2.5-4, then add a small amount of hydroxylamine hydrochloride until the insoluble matter is dissolved by visual observation, then slowly add ammonia water and keep stirring until the pH When the value is 9, the solid phase material is obtained by filtration, washed and then dried, and the obtained material is the ferrous ammonium phosphate precursor. The whole preparation process of ferrous ammonium phosphate precursor is in N 2 carried out under the protection of the atmosphere. Sampling was carried out to analyze the content of P and Fe in the ferrous ammonium phosphate precursor.

[0028] (2) Combine ferrous ammonium phosphate precursor with Li 2 CO 3 , sucrose mixed (if the sampling analysis shows that P:Fe2 CO 3 The ratio of mol...

Embodiment 2

[0034] (1) the ferrous ammonium phosphate precursor obtained in step (1) in embodiment one and Li 2 CO 3 , diammonium hydrogen phosphate, TiCl 4 Mixed with glucose, ferrous ammonium phosphate precursor and Li 2 CO 3 、TiCl 4 The molar ratio with diammonium hydrogen phosphate is determined by making the final product Li:Fe:Ti:P=1:0.95:0.05:1, and the amount of glucose added is determined by the carbon content of 5wt% in the final product lithium ferrous phosphate after roasting. With distilled water as the dispersion medium, in N 2 Ball milling in atmosphere for 2 to 5 hours. N 2 Dry in atmosphere.

[0035] (2) Carry out the pre-baking and roasting process in the same method as in Example 1 to obtain carbon-coated lithium ferrous phosphate (doped with titanium). The fabrication and electrochemical performance testing of practical batteries and button batteries were carried out in the same manner as in Example 1.

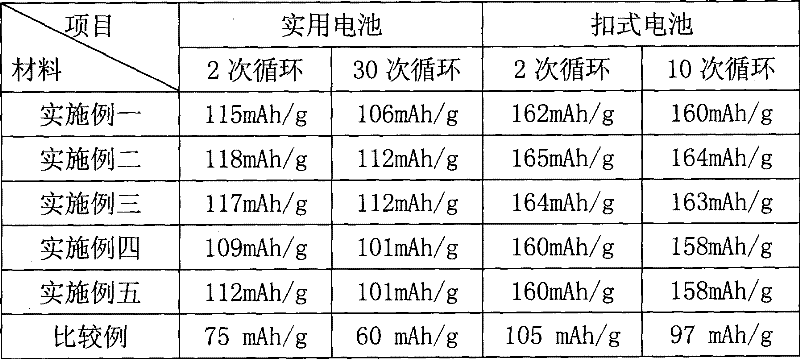

[0036] The electrochemical properties of the materials a...

Embodiment 3

[0038] (1) Take by weighing phosphoric acid, ferrous chloride and magnesium chloride by molar ratio P:Fe:Mg=1:0.95:0.05, in N 2 In the atmosphere, dissolve phosphoric acid, ferrous ammonium sulfate and magnesium chloride in distilled water, adjust the pH value to 2.5-4 with hydrochloric acid, and then add a small amount of ascorbic acid until the insoluble matter is dissolved by visual observation. Add ammonia water slowly and keep stirring until the pH value is 8. The solid phase material is obtained by filtration, the solid phase material is washed and then dried, and the obtained material is the ferrous ammonium phosphate precursor. This preparation process of ferrous ammonium phosphate precursor is in N 2 carried out under the protection of the atmosphere. Sampling was carried out to analyze the content of P and Fe in the ferrous ammonium phosphate precursor.

[0039] (2) Combine the obtained ferrous ammonium phosphate precursor with Li 2 CO 3 Mix with dextrin (if the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com