Mask target and method for forming the same

An alignment mark and groove technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of difficult acquisition of alignment signals, difficult alignment, etc., to achieve easy optical signals, and to solve the problem of decreased alignment accuracy or inability to achieve alignment. alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A new type of alignment mark of the contact window layer according to the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

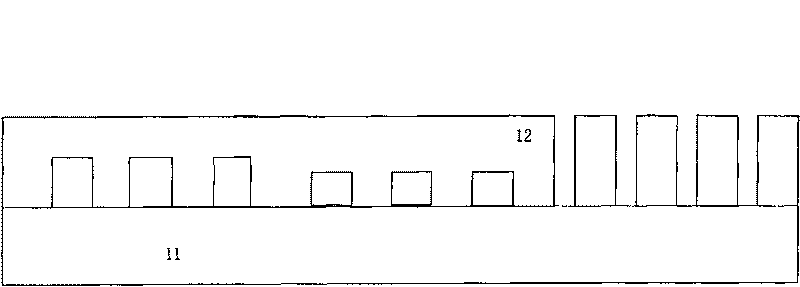

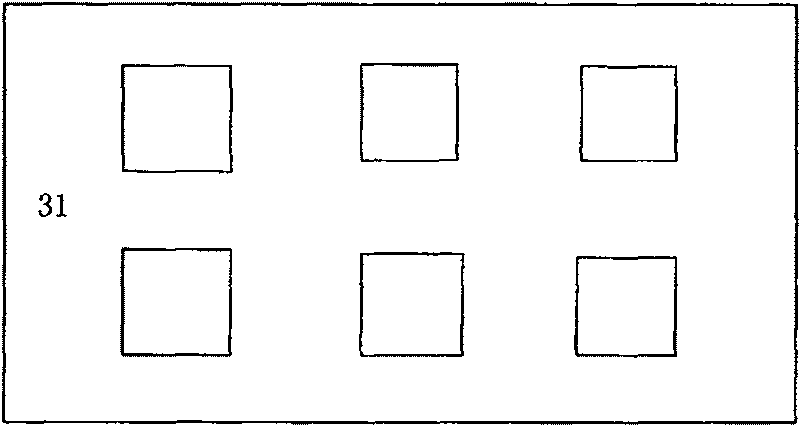

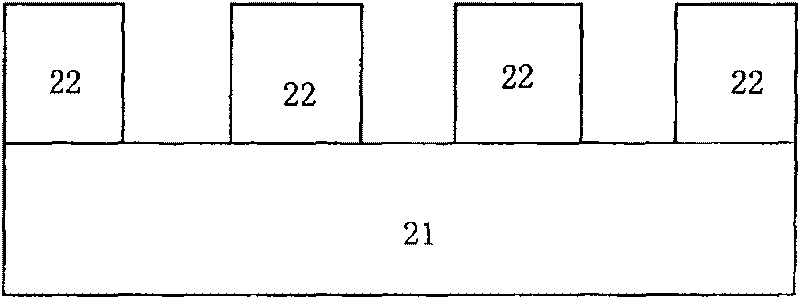

[0022] Figure 2A and 2B For the first step of the alignment mark in a preferred embodiment of the present invention, the field oxide layer 22 on the single crystal silicon substrate 21 is photolithographically or etched using the active layer mask 31, and the alignment mark is placed on the scribe line area begins to etch, forming a trench, shaped like Figure 2B As shown, in this embodiment, the thickness of the field oxide layer 22 is 1 μm. Of course, the thickness of the field oxide layer, the number and shape of trenches can be arbitrary, and are not limited by this embodiment.

[0023] Figure 3A and 3B For the second step of the alignment mark of a preferred embodiment of the present invention, first add a gate polysilicon layer 23 on the field oxide layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com