Compressor

A technology for compressors and space compression, applied in the field of compressors, which can solve problems such as reduced compressor performance, insufficient oil supply, and increased high and low pressure differences, and achieve the effects of reducing vibration, reducing pulsation, and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

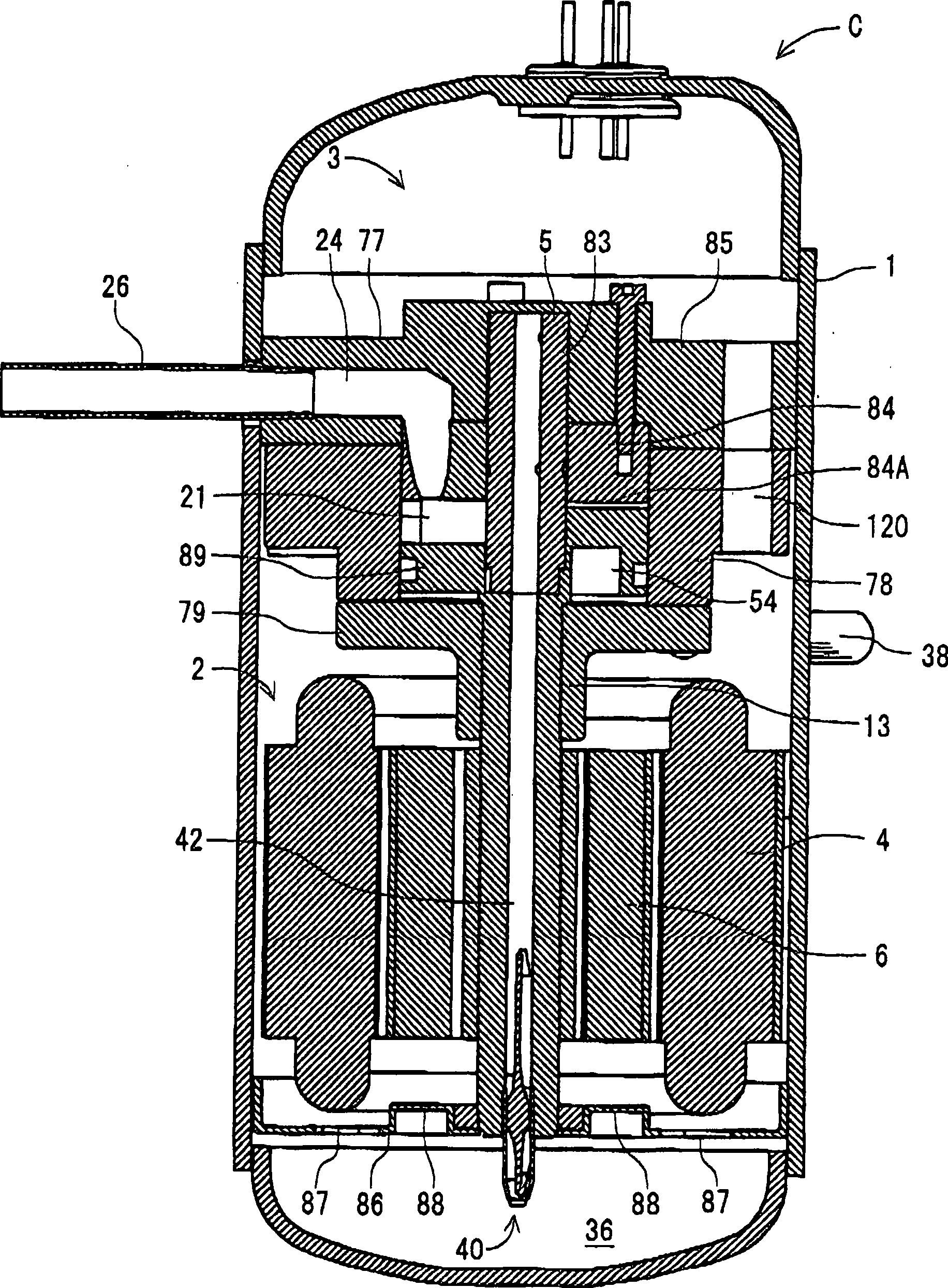

[0040] Fig. 1 shows a longitudinal sectional side view of a compressor C according to a first embodiment of the present invention, figure 2 Another longitudinal sectional side view showing the compressor C of Fig. 1, image 3 Another longitudinal sectional side view showing the compressor C of FIG. 1, Figure 4 A perspective view showing a compression element 3 of the compressor 1 in FIG. 1 .

[0041] In each figure, 1 is an airtight container, and in this airtight container 1, the compression element 3 is accommodated in the upper side, and the drive element 2 is accommodated in the lower side, respectively. That is, the compression element 3 is arranged above the driving element 2 .

[0042] The driving element 2 is a motor, and includes: a stator 4 fixed to the inner wall of the airtight container 1 and wound with a stator coil; and a rotor 6 having a rotating shaft 5 inside and at the center of the stator 4 .

[0043] The compression element 3 has: a support member 77 f...

Embodiment 2

[0074] Below, refer to Figure 5 ~ Figure 7 A second embodiment of the present invention will be described. Figure 5 ~ Figure 7 It is a vertical side view of such a compressor C, and each figure shows a different cross section. In addition, in Figure 5 ~ Figure 7 In the above figure 1~ Figure 4 Components shown with the same numbers exert the same or similar effects, and therefore explanations are omitted.

[0075] In this embodiment, the drive element 2 is accommodated on the upper side and the compression element 3 is accommodated on the lower side in the container 1 . That is, the compression element 3 is arranged below the drive element 2 .

[0076] The compression element 3 is composed of a main support member 107 fixed to the inner wall of the airtight container 1, a cylinder 108 mounted on the lower side of the main support member 107 with bolts, a compression member 109 arranged in the cylinder 108, a vane 11, and a discharge valve 12. It is composed of a sub-s...

Embodiment 3

[0100] the following, Figure 8 ~ Figure 10 represents a compressor C of a third embodiment of the present invention, Figure 8 ~ Figure 10 It is a vertical side view of the compressor C of the third embodiment, and each figure shows a different cross section. In addition, in Figure 8 ~ Figure 10 Attached to the above Figure 1 ~ Figure 7 Components shown with the same numbers have the same or similar effects, and therefore explanations are omitted.

[0101] At this time, the drive element 2 is accommodated on the lower side and the compression element 3 is accommodated on the upper side in the airtight container 1, and the compression space 21 of the compression element 3 is used as the lower surface side of the drive element 2 side of the compression member 109, and the lower surface of the compression member 109 is 113 is formed in a continuously inclined shape from the top dead center to the bottom dead center.

[0102] In addition, a slit 16 is formed in the main sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com