Intelligent tension-adjusting gear

A tension adjusting device and intelligent technology, applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problem of inconvenient operation, manual wire taking, wire feeding and tightening, and the surface roughness and dimensional accuracy of the workpiece are very high. It is difficult to achieve an ideal range and other problems to achieve the effect of ensuring accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

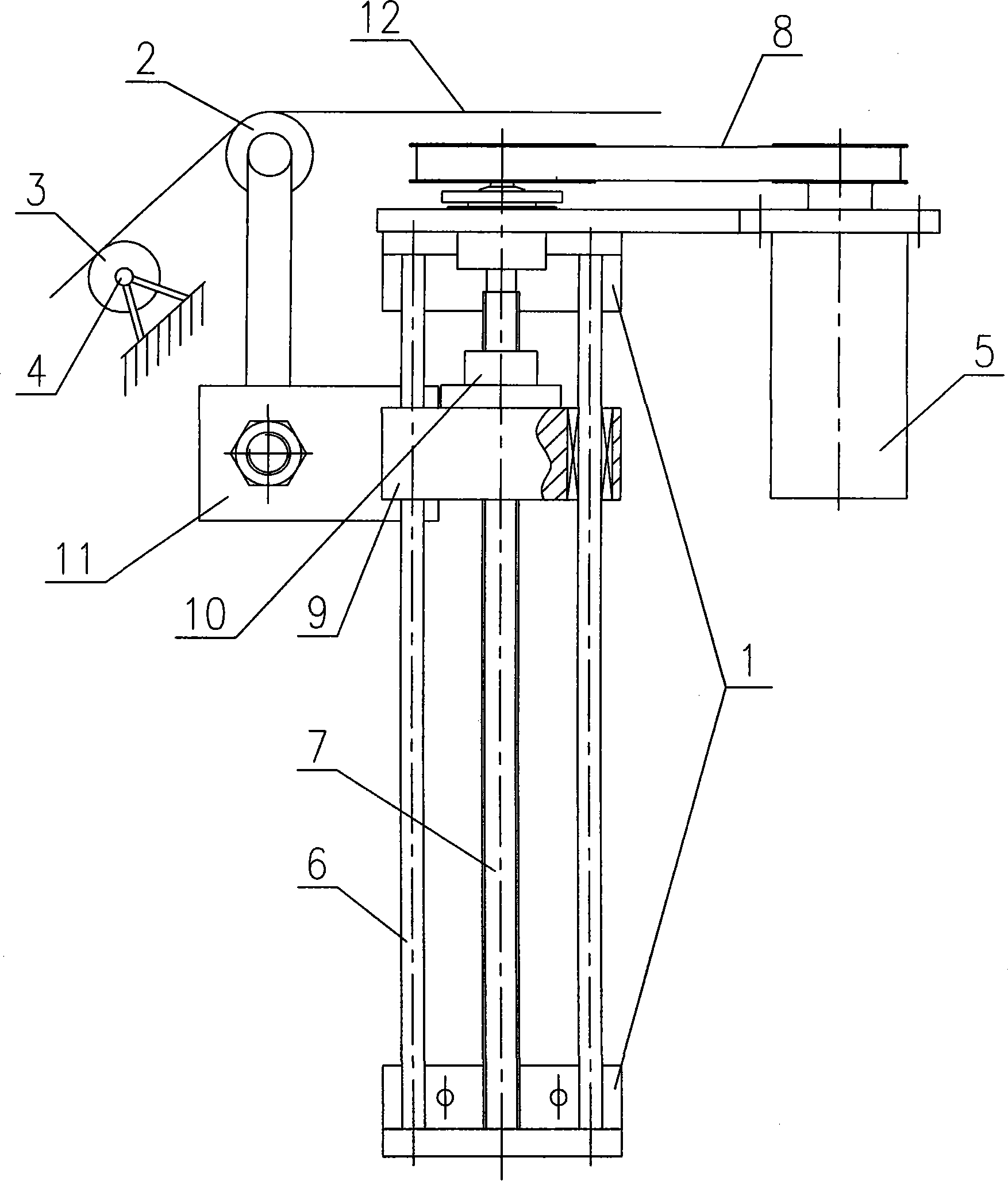

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

[0008] Depend on figure 1 As shown, the intelligent tension adjustment device includes a support 1, a guide wheel 2, a tension detection wheel 3, a pressure sensor 4 as a tension detection wheel mandrel, a single-chip microcomputer (not shown), and a servo motor installed on the support 1 5 and two parallel guide posts 6, and a ball screw nut pair, wherein the ball screw 7 is mounted on the support 1 and parallel to the two guide posts 6, the servo motor 5 and the ball screw 7 are connected through a synchronous pulley mechanism 8, A sliding seat 9 is fixedly connected with the nut 10 and is slidably mounted on two guide columns 6 through a linear bearing, the guide wheel 2 is connected with the sliding seat 8 through a connecting block 11, and the single-chip microcomputer is respectively connected with the pressure sensor 4 and the servo motor 5 ;

[0009] When in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com