Paper containing preaggregated filler and process for producing the same

A manufacturing method and technology for base paper, applied in the directions of non-fiber pulp addition, inorganic compound addition, paper, etc., can solve the problems of insufficient paper strength and unsatisfactory quality, and achieve improved paper strength, good printing quality and smoothness. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

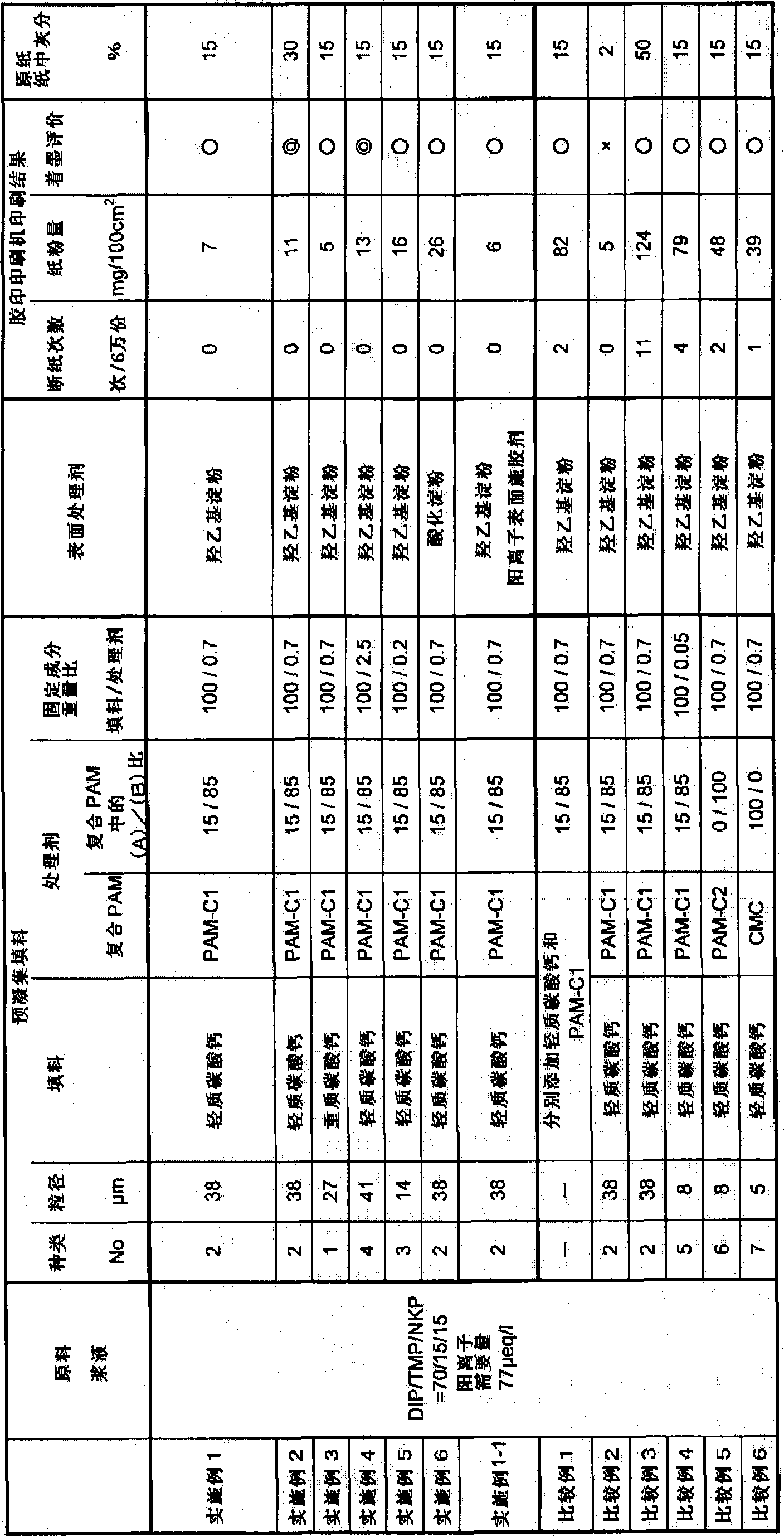

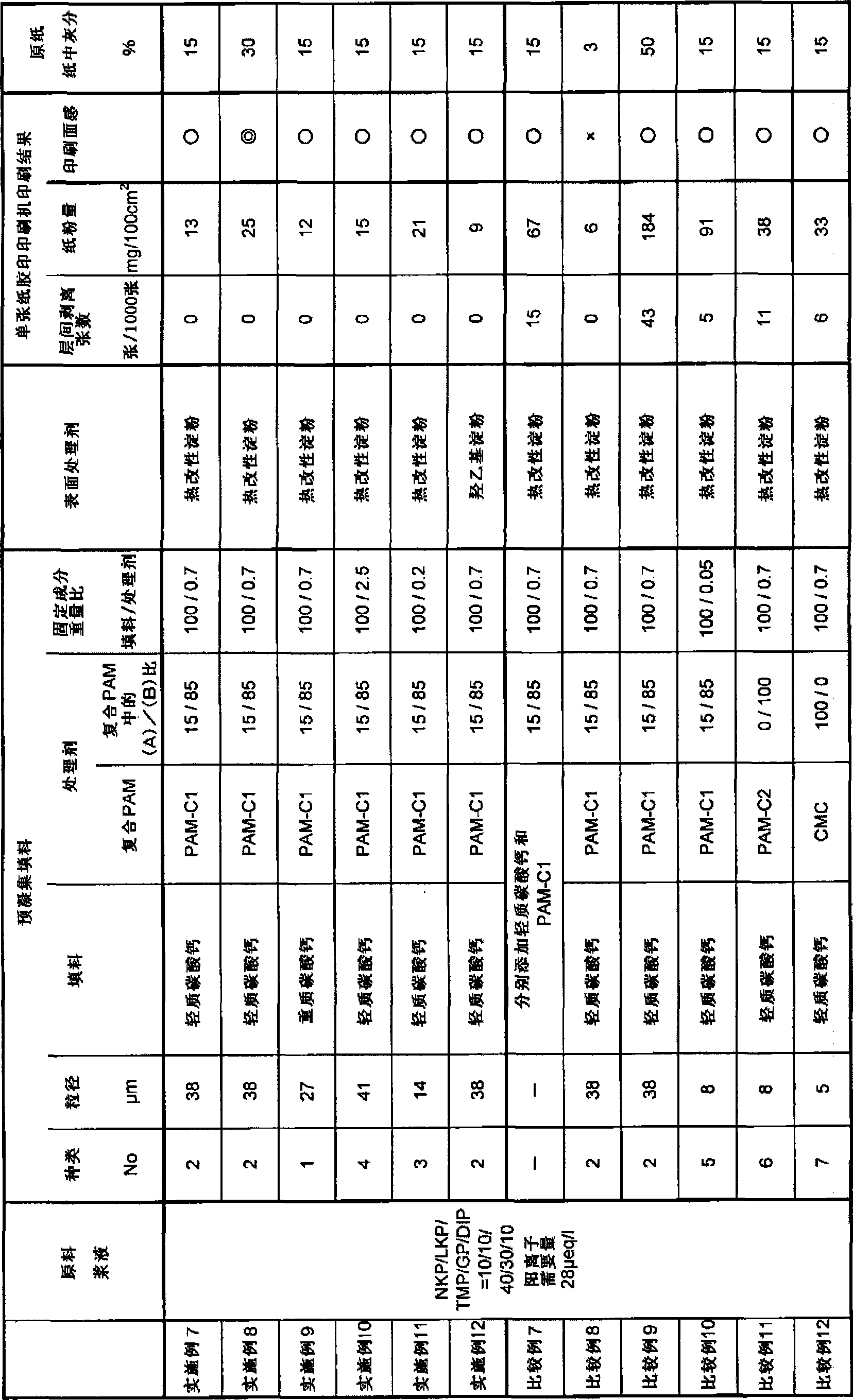

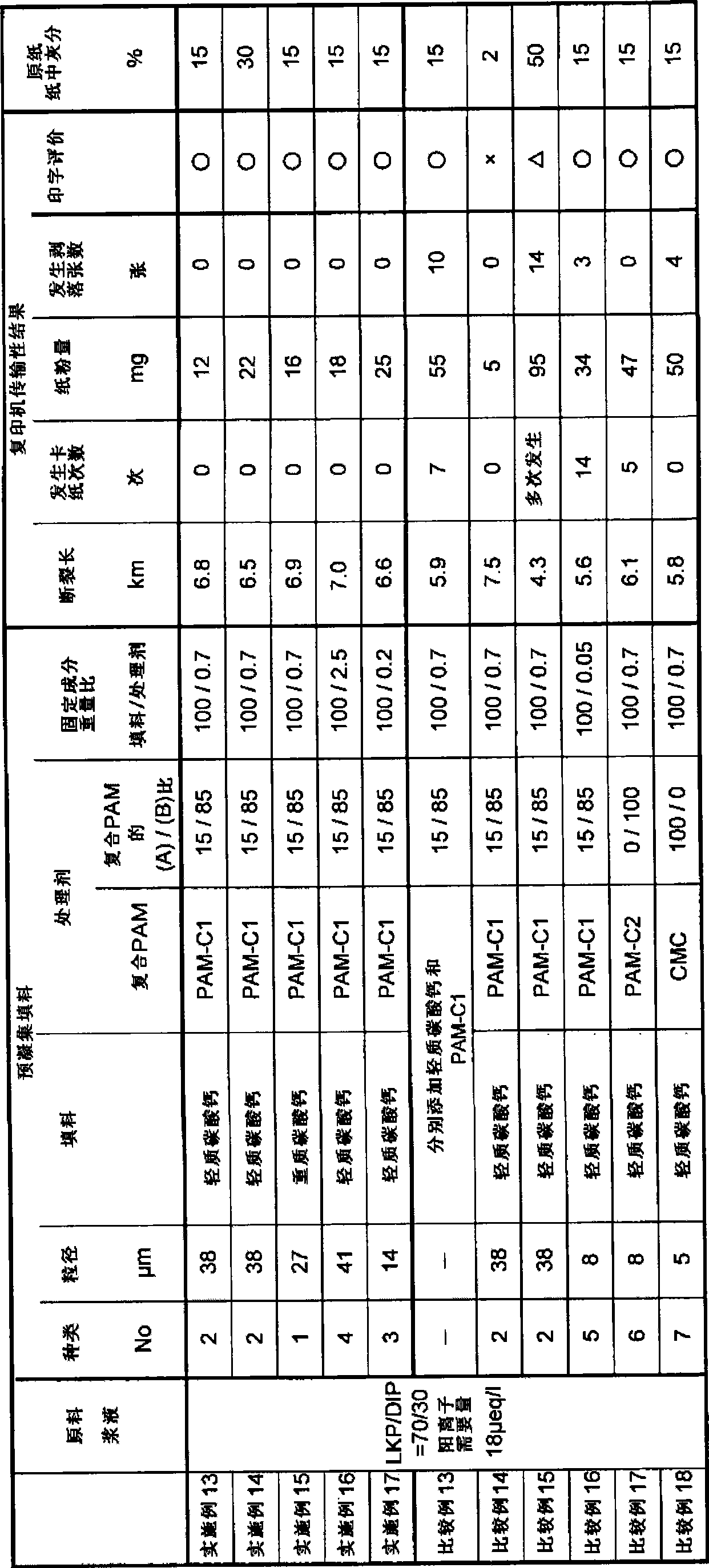

Embodiment 1

[0160] Use a headbox to add the above-mentioned pre-aggregated filler 2 to the slurry of the raw material pulp, use the obtained paper stock for papermaking, and apply hydroxyethyl starch as a surface treatment agent to obtain a paper for offset printing with a filler rate of 15%. Neutral newsprint.

Embodiment 2

[0162] Use a headbox to add the above-mentioned pre-agglomerated filler 2 to the slurry of the raw material pulp, use the obtained paper stock for papermaking, and apply hydroxyethyl starch as a surface treatment agent to obtain a paper for offset printing with a filler rate of 30%. Neutral newsprint.

Embodiment 3

[0164] Use a headbox to add the above-mentioned pre-aggregated filler 1 to the slurry of the raw material pulp, use the obtained paper stock for papermaking, and apply hydroxyethyl starch as a surface treatment agent to obtain a paper for offset printing with a filler rate of 15%. Neutral newsprint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com