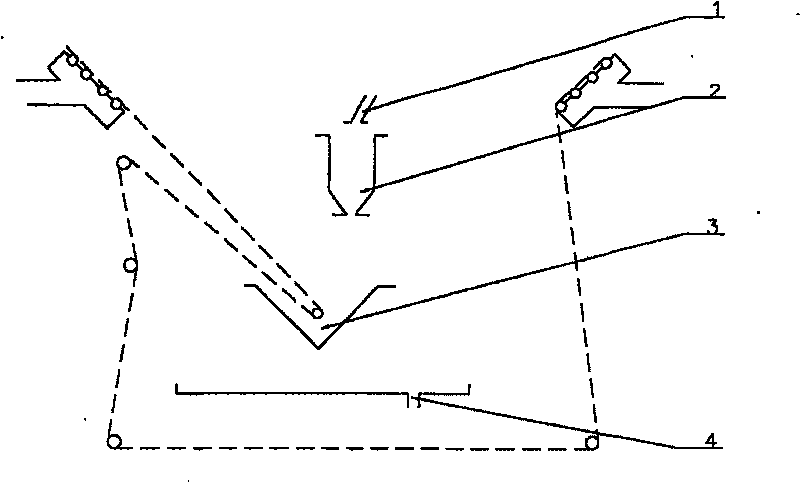

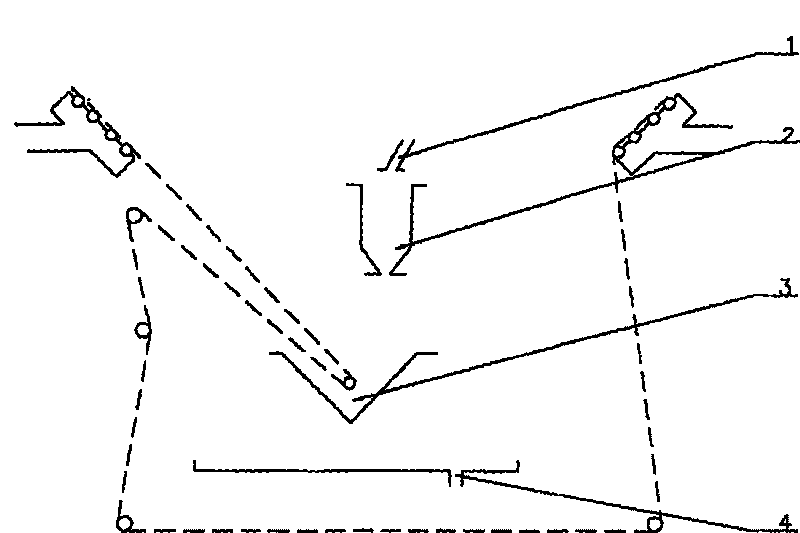

Bead planting technique used for high-strength reflecting film production

A technology of reflective film and bead planting, which is applied in the direction of optics, optical components, and devices for coating liquid on the surface, etc. It can solve the problems of overlapping floating beads on the surface of bead planting, achieve enhanced retroreflective performance, increase density, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] Select glass microspheres with a particle size of 60 microns to 90 microns and a refractive index Nd=1.93, conduct destaticizing treatment on qualified glass microspheres, and then put them into an oven to preheat the glass microspheres to 85~90°C, and then put them Into the high-position bead tank, the glass beads are added at a constant speed, and then fall from the high-position bead tank into the bead planting tank, and the glass beads are negatively charged by the electrostatic device in the bead planting tank.

[0021] A 50-micron thick polyethylene terephthalate (BOPET) film is selected as the bead-planting base film, and a 25-micron-thick peelable adhesive layer is coated on the BOPET film to form a bead-planting film, which is then dried in a drying tunnel. , There is static electricity on the film-moving roller of the drying tunnel, and the bead-planting film is positively charged when it passes through the film-moving roller. When the bead planting film passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com