Method for reducing traffic passage noise adopting sponge plate

A sponge board and channel technology, applied in noise absorption devices, buildings, etc., can solve problems such as poor noise reduction effects, achieve the effects of easy disassembly, avoid noise reflection, and reduce noise intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

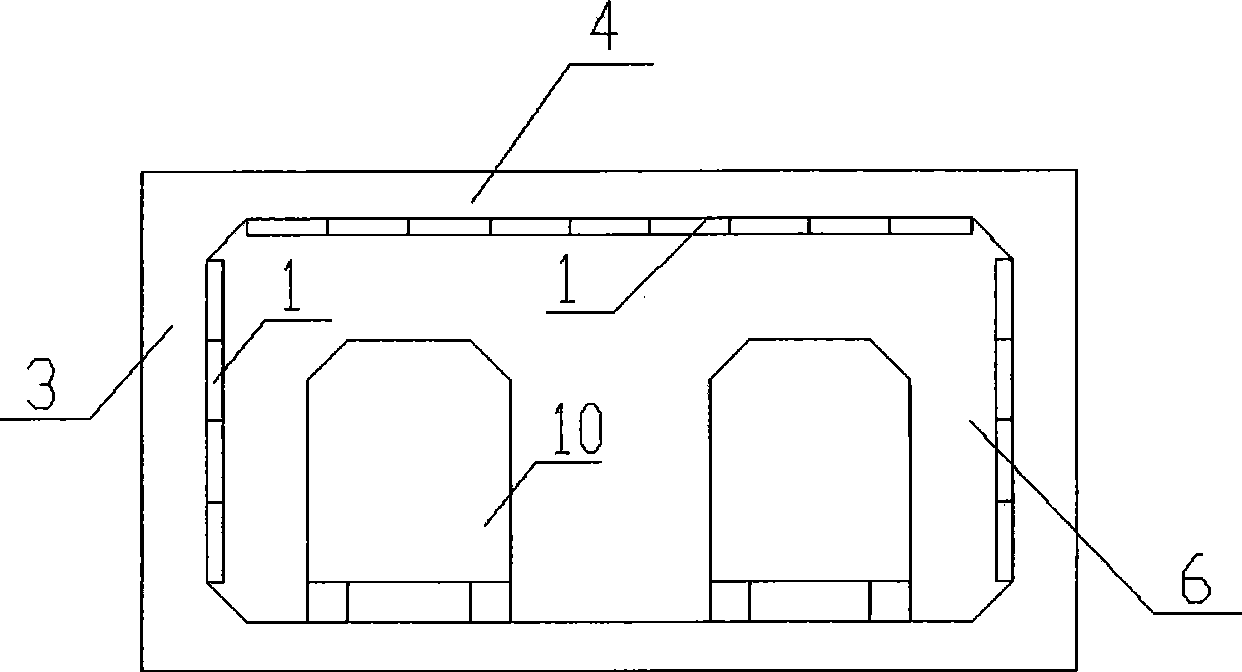

[0023] see figure 1 Install the sponge board 1 on part or all of the walls 3 and top 4 of the rectangular tunnel 6 such as motor vehicle tunnels, motor vehicle tunnels, and rail transit tunnels. The thickness of the sponge board 1 is 5 mm to 500 mm, preferably 20 mm to 200 mm. Consume the noise generated by the friction between the tires of the motor vehicle 10 and the road surface, the noise generated by the friction between the train 11 and the track, thereby reducing the noise intensity in the rectangular tunnel 6, and the sponge board 1 on the wall 3 also has a function when the motor vehicle 10 rubs against the wall 3 buffering effect. The sponge board 1 is made of flame-retardant and sound-absorbing sponge with a wavy surface. The appearance color and pattern of the sponge board 1 can be selected according to the needs of the landscape, so as to realize the integration of traffic noise reduction and landscape.

Embodiment 2

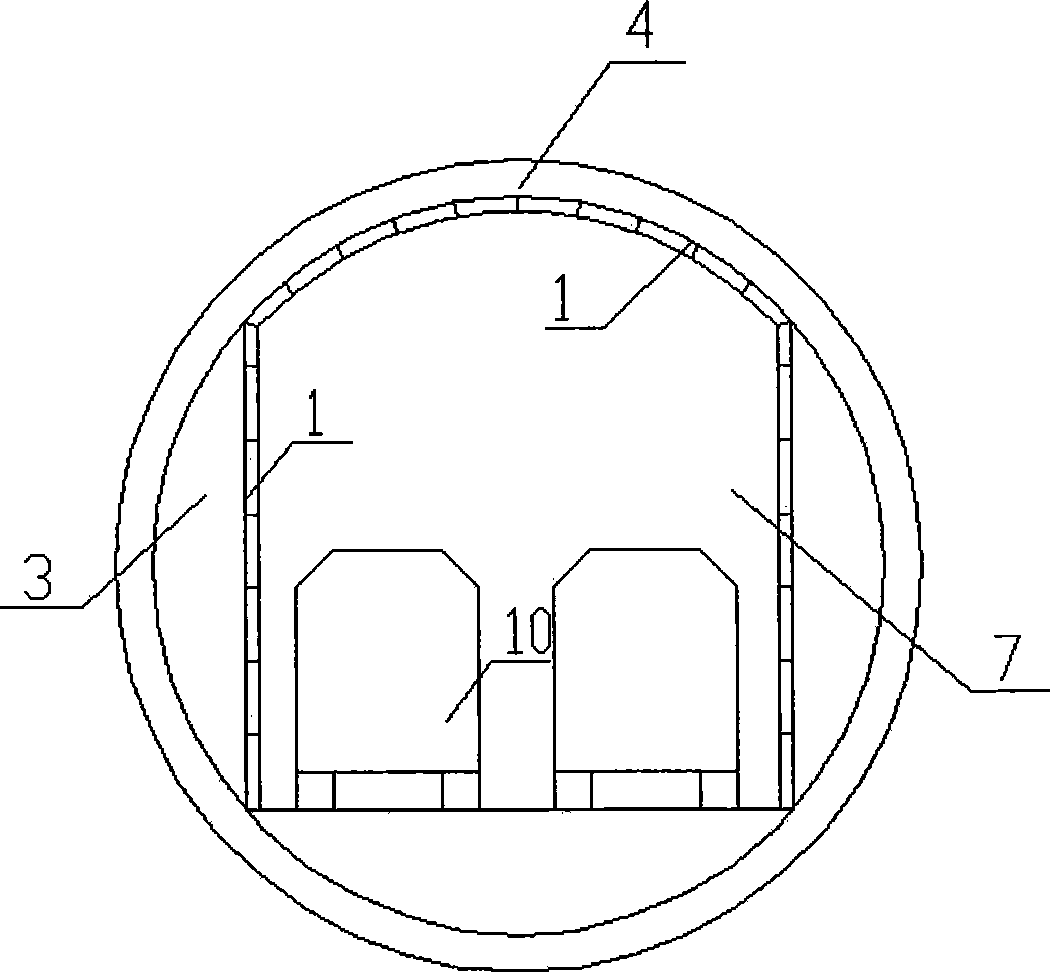

[0025] see figure 2 Install the sponge board 1 on a part or all of the wall surface 3 and the top surface 4 of the circular tunnel 7 such as a motor vehicle tunnel, a motor vehicle tunnel, and a rail transit tunnel. The thickness of the sponge board 1 is 5 mm to 500 mm, preferably 20 mm to 200 mm. and consume the noise generated by the friction between the tires of the motor vehicle 10 and the road surface, the noise generated by the friction between the train 11 and the track, thereby reducing the noise intensity in the circular tunnel 7, and the sponge board 1 on the wall 3 also has the function of the motor vehicle 10 rubbing against the wall. 3 o'clock cushioning. The sponge board 1 is made of flame-retardant and sound-absorbing sponge with a wavy surface. The appearance color and pattern of the sponge board 1 can be selected according to the needs of the landscape, so as to realize the integration of traffic noise reduction and landscape.

Embodiment 3

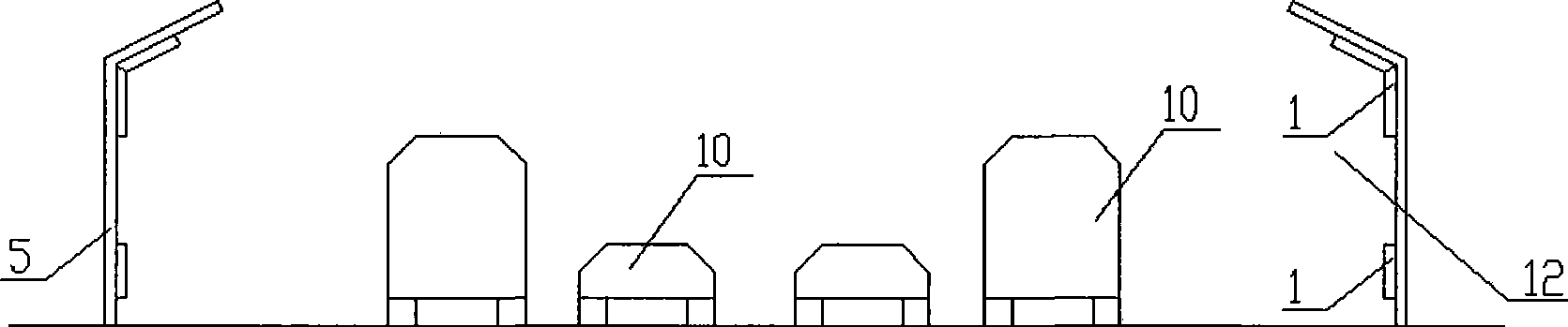

[0027] see image 3 Install a sponge board 1 on a part or all of the sound barrier 5 of the road or highway 12 near the road side, the thickness of the sponge board 1 is 5 mm to 500 mm, and the preferred value is 20 mm to 200 mm, so as to absorb and consume the noise generated by the friction between the tires of the motor vehicle 10 and the road surface, Thereby reducing the noise intensity inside and outside the road or highway 12, and the sponge board 1 also has a buffering effect when the motor vehicle 10 rubs against the sound barrier 5. The sponge board 1 is made of flame-retardant and sound-absorbing sponge with a wavy surface. The appearance color and pattern of the sponge board 1 can be selected according to the needs of the landscape, so as to realize the integration of traffic noise reduction and landscape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com