Combination type prestressed concrete box beam

A concrete box girder and prestressed technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of unsuitable cast-in-place prestressed concrete box girder, high construction cost of full-house support, and difficulty in erecting full-house support, etc. The effect of stable quality, ensuring consistency and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiment; It can be clearly seen from Fig. 1 that the combined prestressed concrete box girder is composed of 2 prefabricated parts 1 with "τ" shape in cross section and 6 prefabricated parts 2 with "I" shape in cross section arranged in parallel.

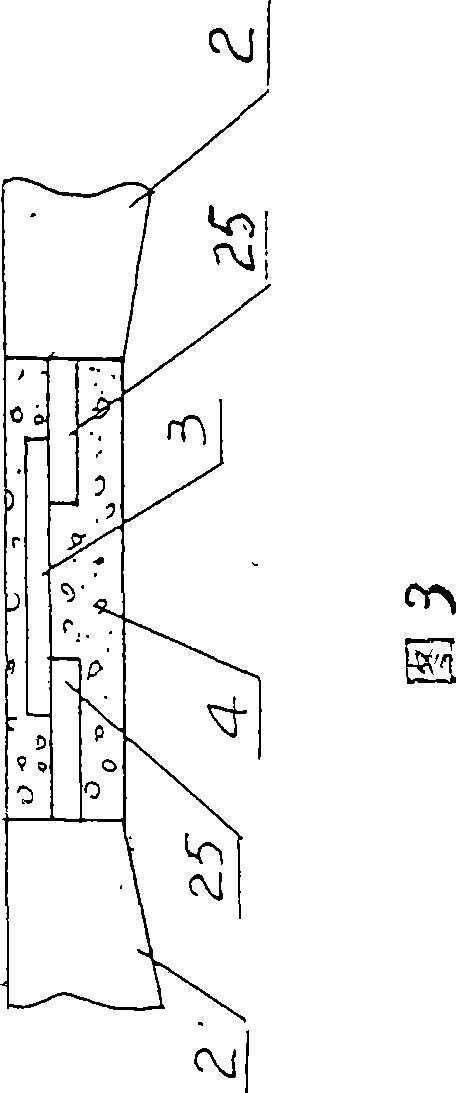

[0021] The ends of the upper top plate 11 and lower bottom plate 12 of the “τ” shaped prefabricated part 1 and the upper top plate 21 and lower bottom plate 22 of the “I” shaped prefabricated part 2 are arranged with exposed steel bars 13 (see Figure 2).

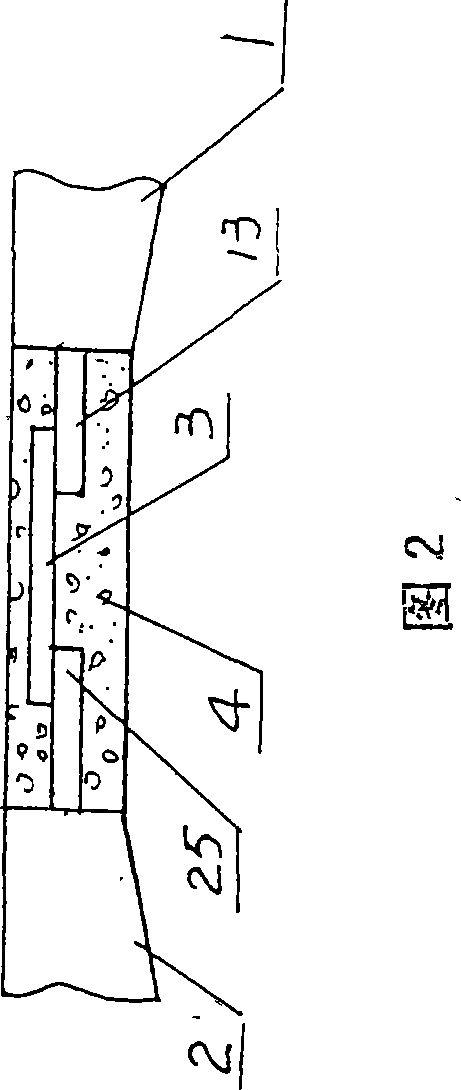

[0022] The upper top plate 21 and the lower bottom plate 22 of the "I" shape preform 2 are connected with the upper top plate 11 and the lower bottom plate 12 of the "τ" shape preform 1 / and with the upper top plate 21 and the lower bottom plate 2 of other "I" shape preforms 2 The butt ends 23 and 24 of the bottom plate 22 are arranged with exposed steel bars 25 (see FIGS. 2 and 3 ).

[0023] Arrange the upper top plate 21 ends and the lower bottom plate 22 ends of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com