Suspended bed type air antivibration sleeve

A shock-proof cover, hammock-type technology, applied in the direction of containers to prevent mechanical damage, packaging of fragile items, containers, etc., can solve the problems of loss of buffer protection, limited shock absorption capacity of small airbags, inability to achieve buffer shock absorption, etc., to achieve good buffer protection. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

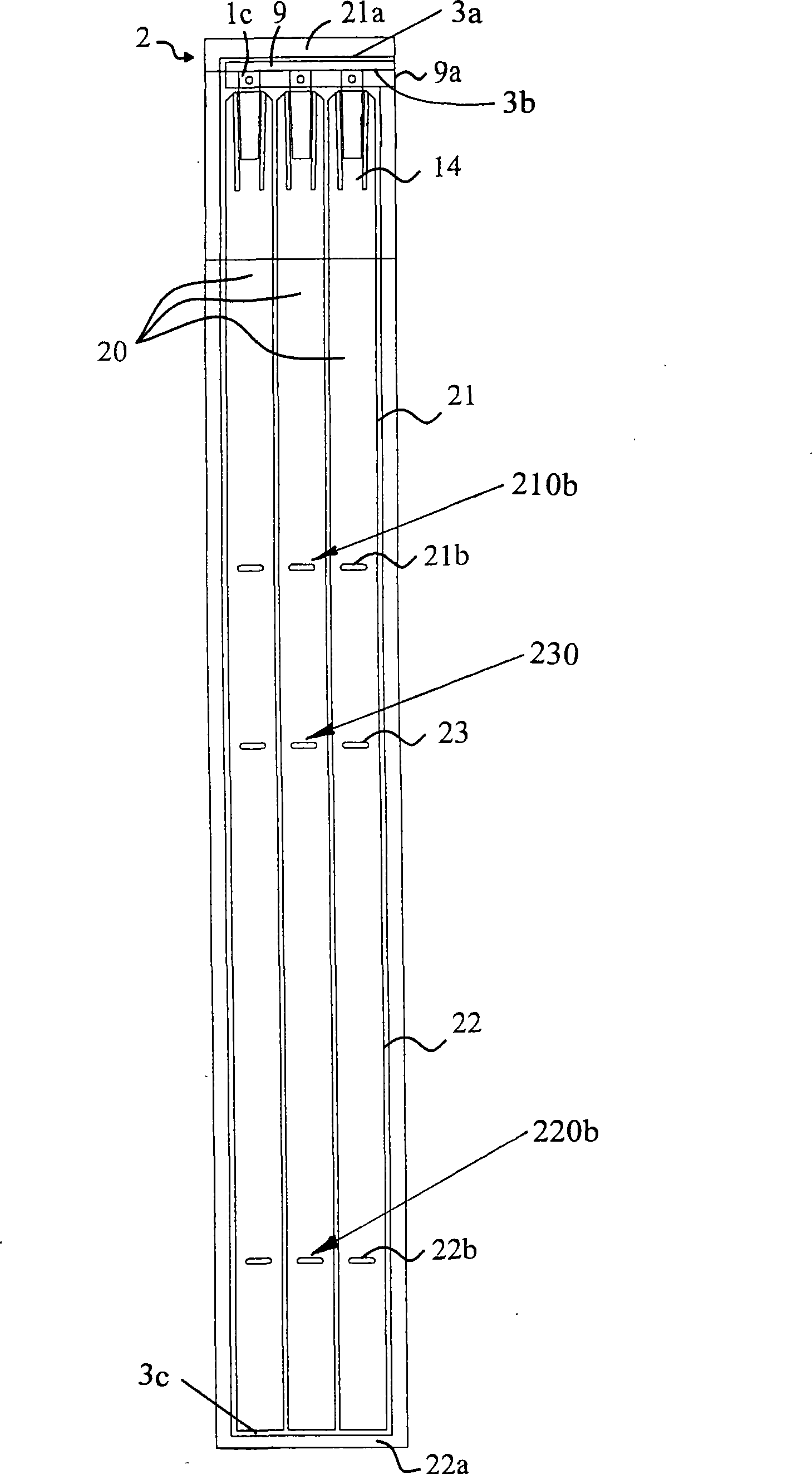

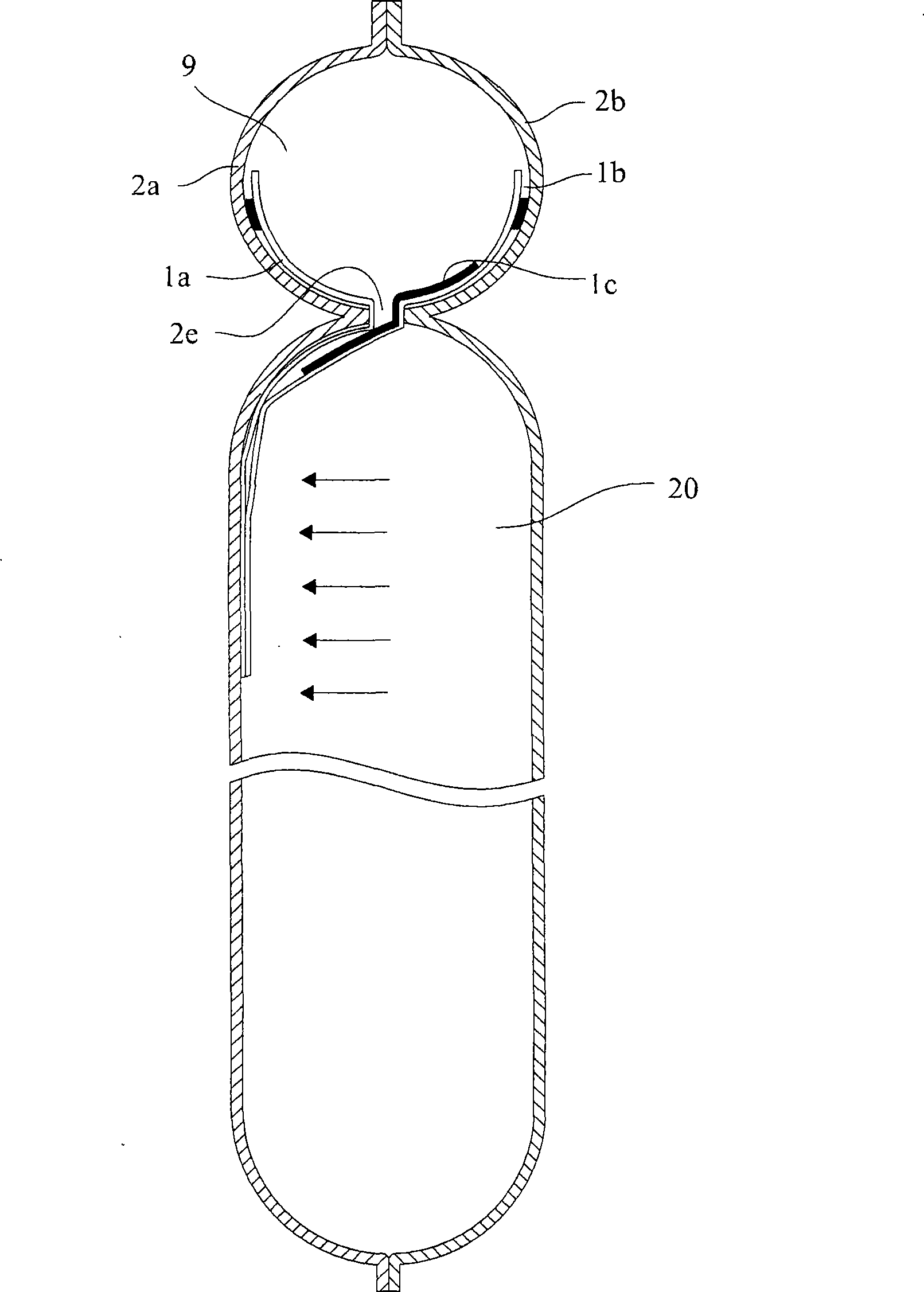

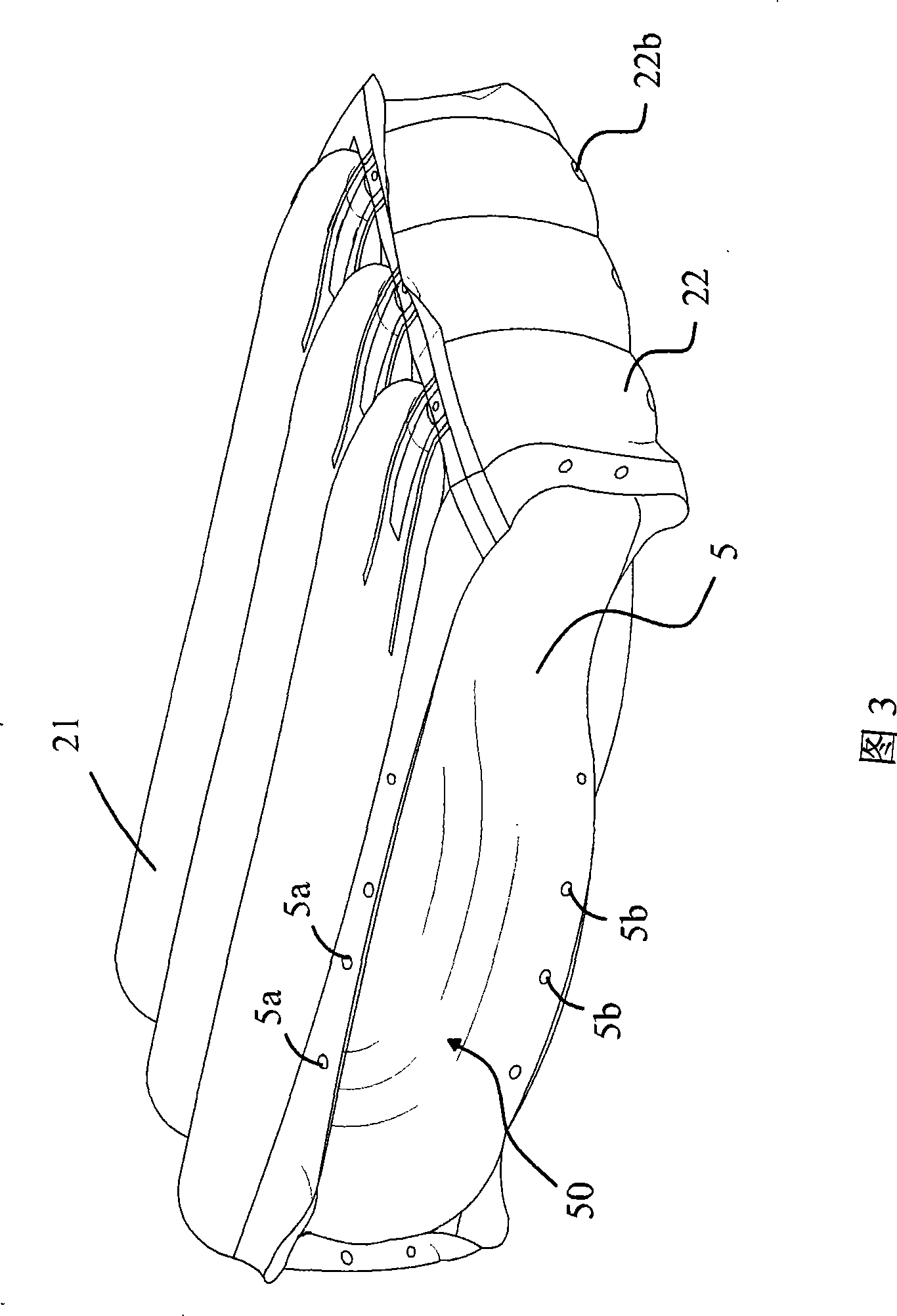

[0030] figure 1 , figure 2 ,image 3, Figure 4A , Figure 4B with Figure 4C Shown is a hammock type air shock boot according to a first embodiment of the present invention.

[0031] The hammock type air shockproof cover of the present invention is used to cover articles and provide buffer protection for the articles, which includes: air column sheet 2 and buffer sheet 5 .

[0032] Described air column sheet 2 comprises two outer films 2a, 2b stacked up and down, and two outer films are made of polyethylene (polyethylene, PE), and the peripheries of two outer films are bonded by heat-sealing lines so that the air column sheet has The first heat-sealed edge 21a, the second heat-sealed edge 22a, the joint edge 21c and the bottom side 21d. The first heat-sealing line 3b is arranged on the top of the air column sheet and lower than the upper peripheral heat-sealing line 3a, thus forming a possible gap between the upper peripheral heat-sealing line 3a and the first heat-seali...

Embodiment 2

[0043] Figure 5 with Image 6 It is a cross-sectional view and a schematic diagram of a covered article according to the second embodiment of the present invention. See Figure 5 , the difference from the first embodiment is that in this implementation, the bottom side 21c on the first buffer wall 21 and the bottom side on the second buffer wall 22 are not heat-sealed, so that the accommodating space 6 is an open space. When the buffer sheet 5 wraps the article 100, the buffer sheet is pressed down under force to slow down the shaking of the article 100, thereby achieving the function of buffering and shock absorption.

[0044] exist Image 6 Among them, after the buffer sheet 5 is folded in half, its left and right sides are bonded to form two left and right joints 51, so when the object shakes violently and the buffer sheet 5 shakes left and right, the buffer sheet 5 can first slow down the shaking of the object 100, and then The article 100 is buffered and protected by...

Embodiment 3

[0046] Figure 7 with Figure 8 The third embodiment of the present invention. Wherein, the first buffer wall 21 is provided with a plurality of first node interval lines 210b, and the second buffer wall 22 is also provided with a plurality of second node interval lines 220b. Respectively bend the gas column along the bending line 230, two first node interval lines 210b, and two second node interval lines 220b, and then bond the first heat-sealing edge 21a and the second heat-sealing edge 22a with heat-sealing means, so that the first An accommodating space 6 is enclosed between the buffer wall 21 and the second buffer wall 22 , Figure 8 Among them, the accommodating space 6 is roughly hexagonal, and the length of each side changes with the distance between the spacing lines. When changing the number or position of the interval lines on the first buffer wall 21, or changing the number or position of the interval lines on the second buffer wall 22, the accommodating space 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com