Earthing fault detection and control method for electromagnetic stirring system

An electromagnetic stirring and grounding fault technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of accidental power failure of non-faulty electric stirring, reduce the yield of continuous casting slabs, and cannot quickly and accurately judge faulty electric stirring grounding Equivalence issues, to achieve accurate judgment, reduce impact, and ensure continuous and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

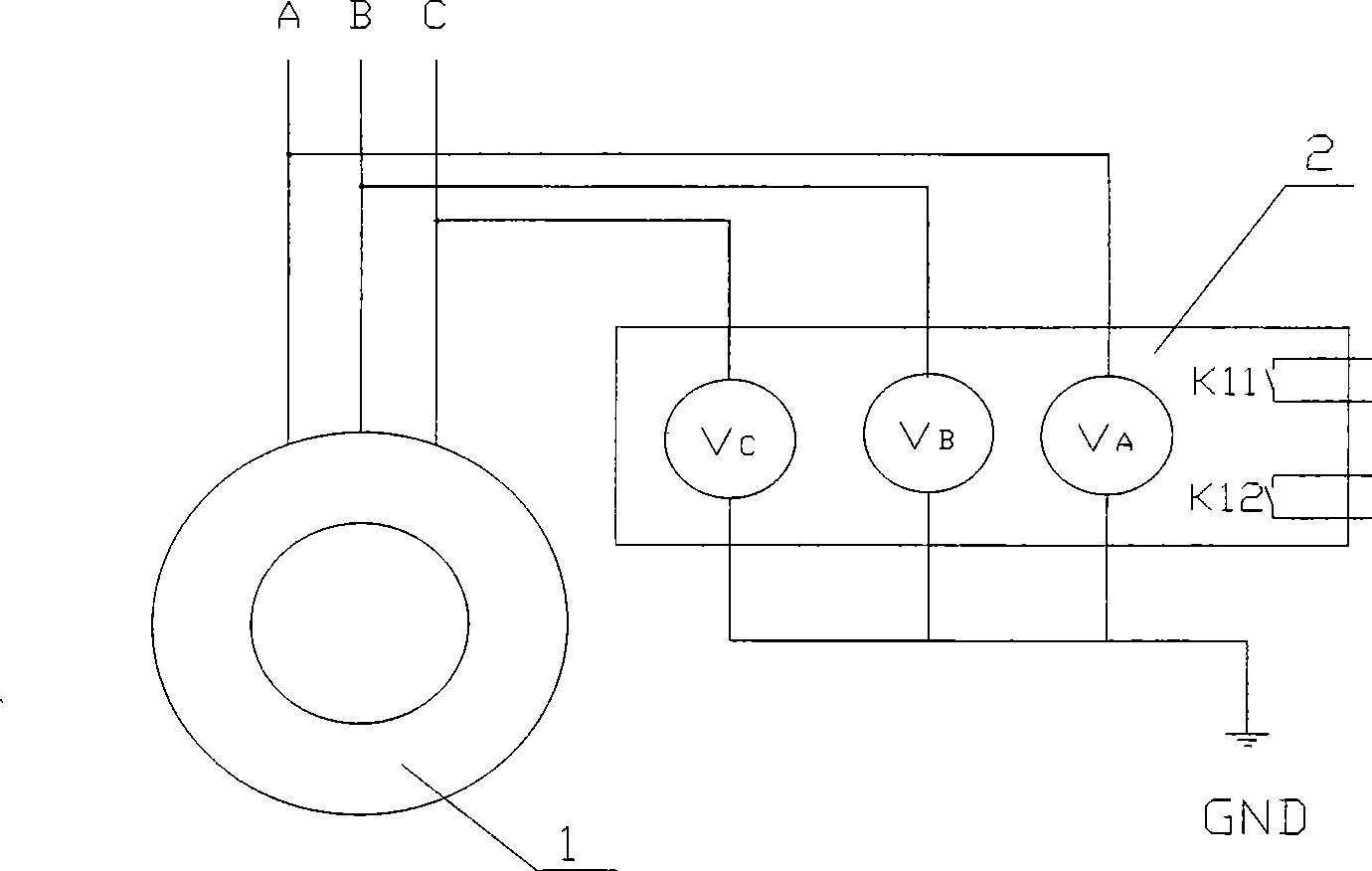

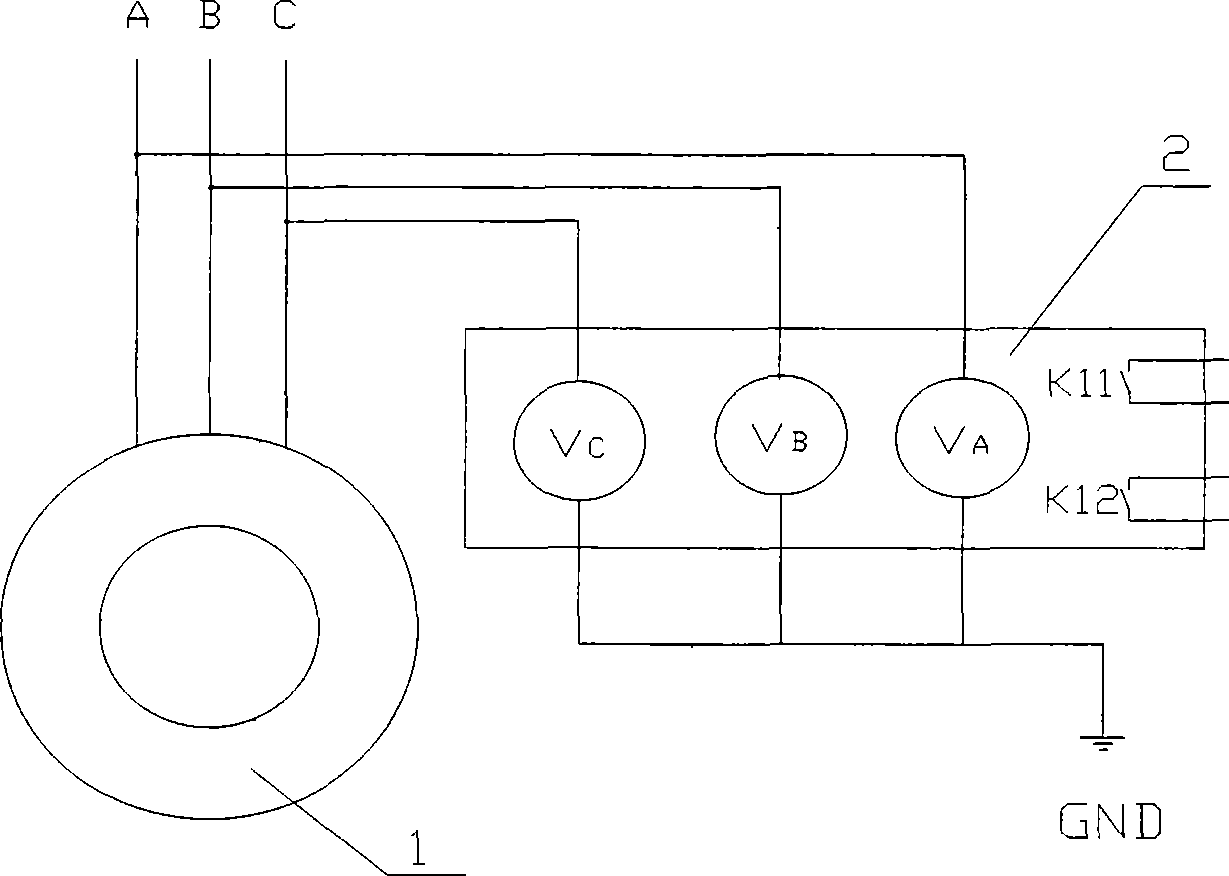

[0015] Such as figure 1 As shown, for a certain circuit of the multi-circuit and multi-machine electromagnetic stirring system, the A, B, and C three-phase cables of the electromagnetic stirring coil 1 are connected in series with the intelligent instrument 2 at the outlet end of the inverter cabinet of the electromagnetic stirrer. Smart Meter 2 is a general-purpose meter for voltage measurement, which includes V A , V B , V C The three voltmeters correspond to the real-time detection of A, B, and C three-phase voltage values. The first relay switches K11 and K12 are respectively connected to different input points of the PLC control module of the electromagnetic stirring system, and the second relay switch K12 controls the alarm signal light and the buzzer through the PLC of the electromagnetic stirring system. When one of the phases of the electric stirring equipment in a certain circuit is grounded, the ground-to-ground voltage value will be greatly reduced, and the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com