Push button switch

A switch and shell technology, applied in the field of buckle switches, can solve the problems of unstable contact state of peripheral fixed contacts, difficulty in ensuring contact pressure, and reduced switch performance, and achieve the effect of superior switch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The best mode for implementing the snap switch of the present invention will be described with reference to the drawings.

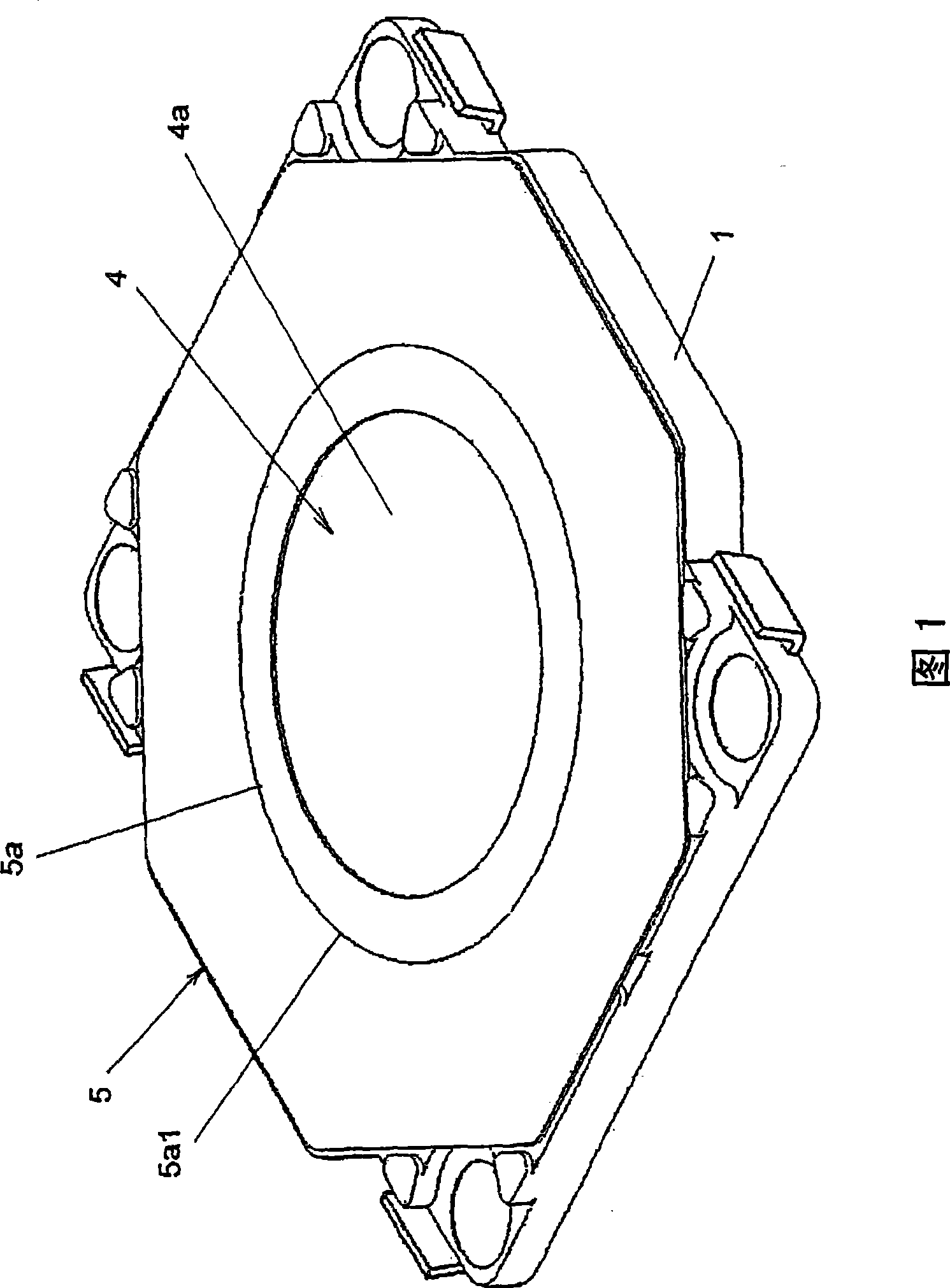

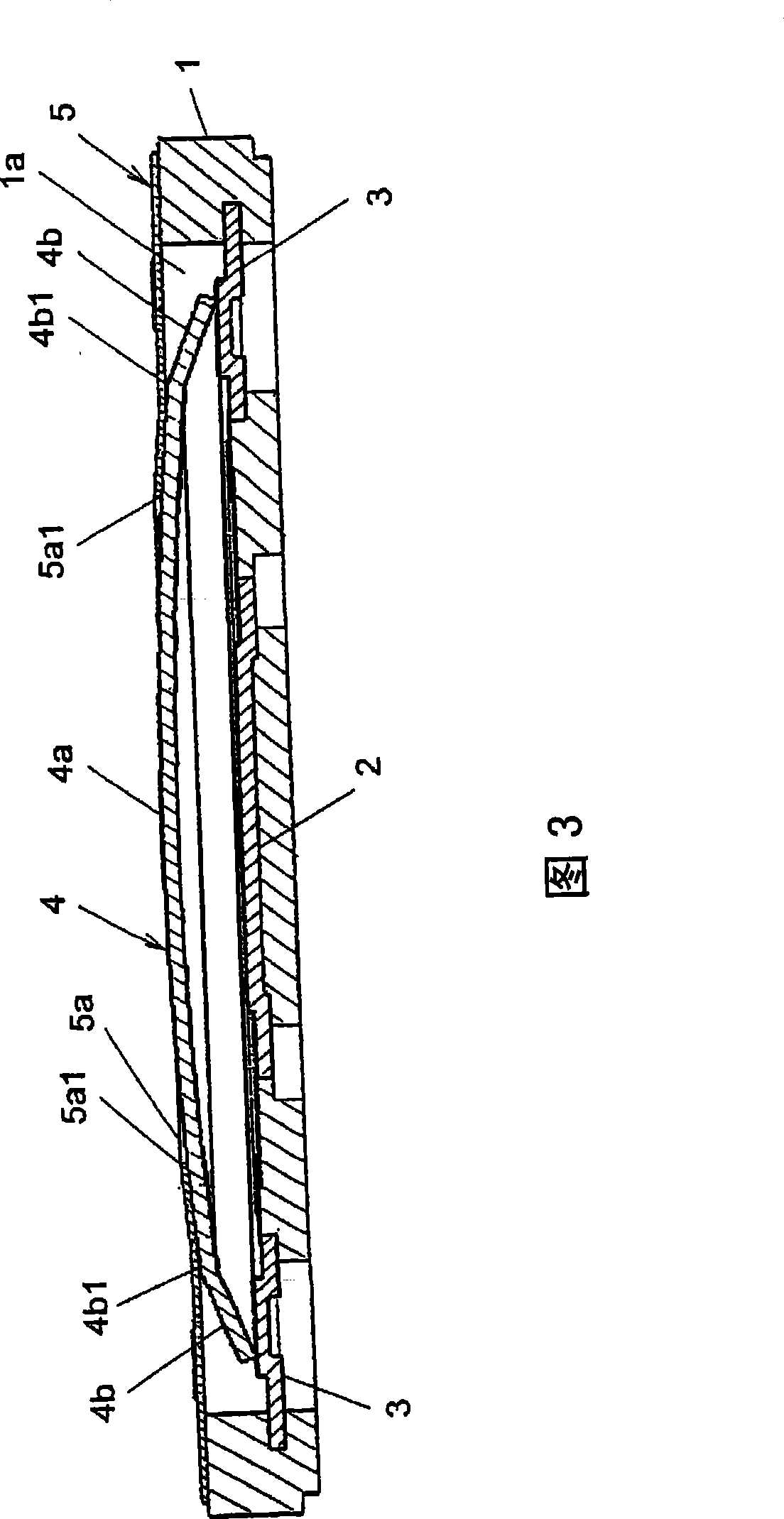

[0033] FIG. 1 is a perspective view showing an embodiment of a push switch according to the present invention, figure 2 It is an exploded perspective view of this embodiment, and FIG. 3 is a longitudinal sectional view of this embodiment.

[0034] As shown in these FIGS. 1 to 3 , in this embodiment, there are: a housing 1 with an opening on the upper surface, a housing portion 1 a, and made of an insulating material such as synthetic resin; The central fixed contact 2 and the peripheral fixed contacts 3. In addition, there is a movable contact 4 housed in the housing portion 1 a of the case 1 and always conducting with the peripheral fixed contacts 3 and selectively conducting with the central fixed contact 2 .

[0035] The movable contact 4 is formed by stamping a conductive thin metal plate made of phosphor bronze or stainless steel with a surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com