Back light module unit and LCD device

A technology for liquid crystal display devices and backlight modules, applied in light guides, optics, optical components, etc., can solve problems such as poor brightness of backlight modules, and achieve the effects of low viscosity requirements, reduced thickness, and improved light output brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] see Figure 5 , is a schematic perspective view of the first embodiment of the liquid crystal display device of the present invention. The liquid crystal display device 2 includes a liquid crystal panel 29 and a backlight module 20 adjacent to the liquid crystal panel 29 .

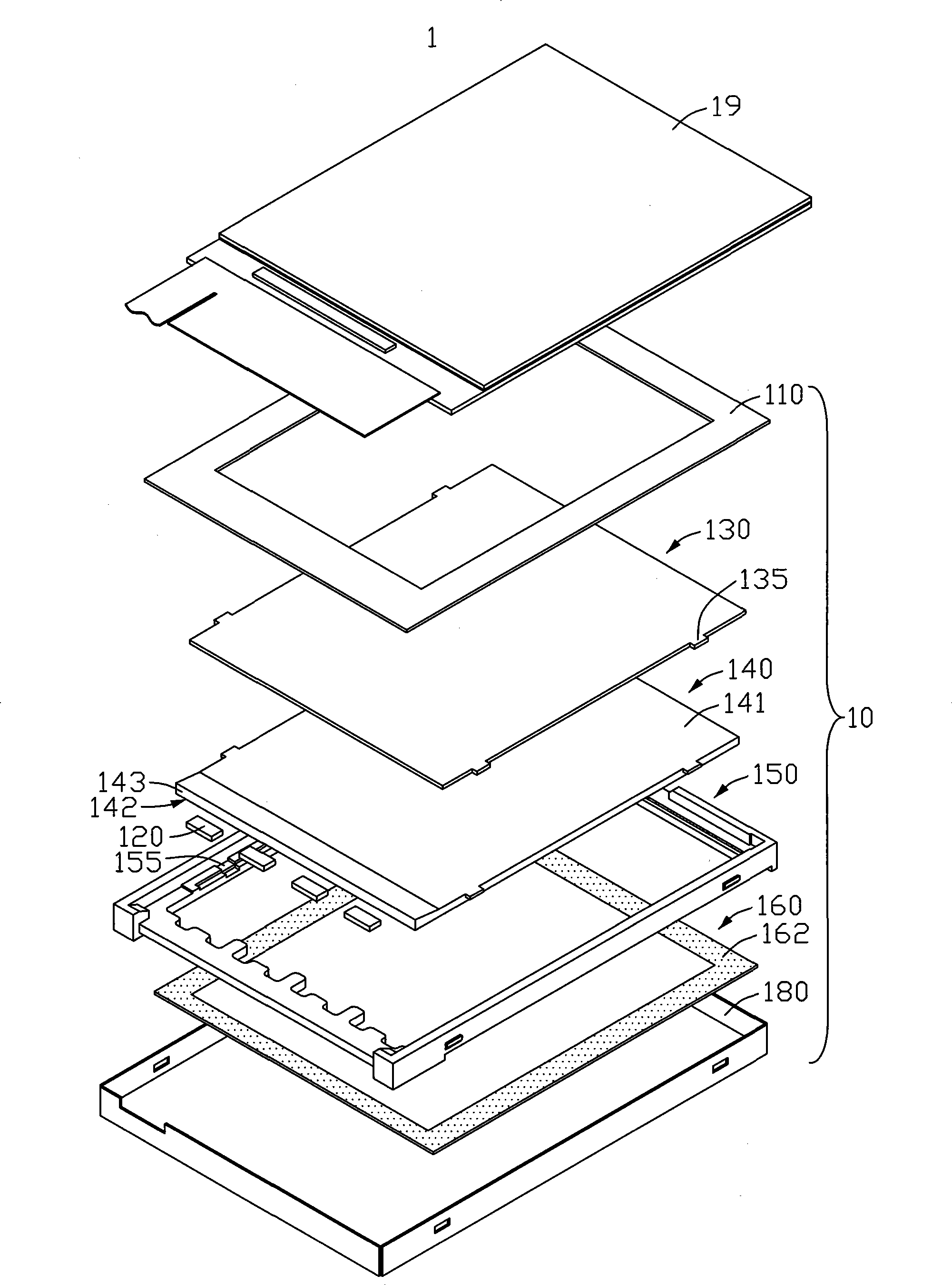

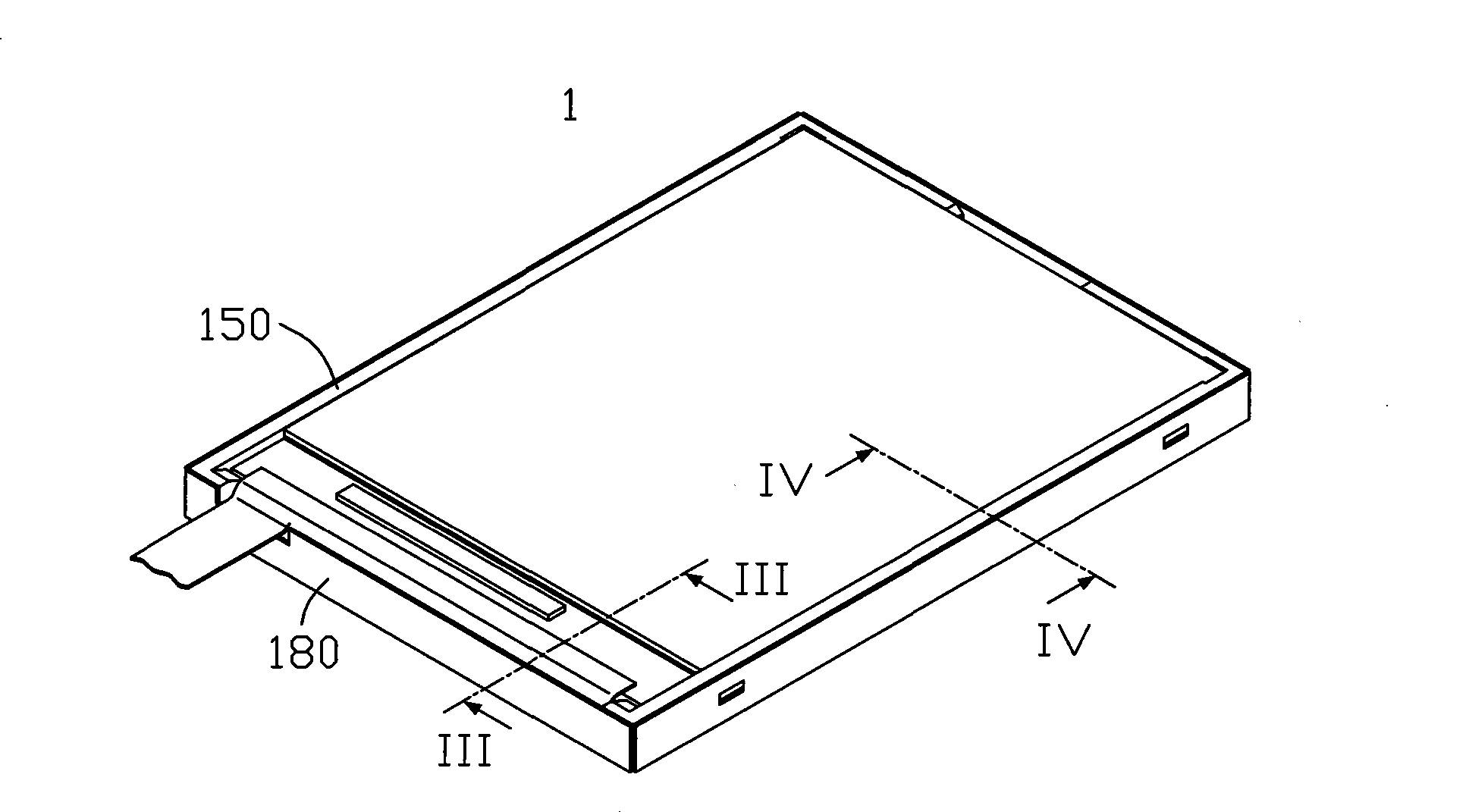

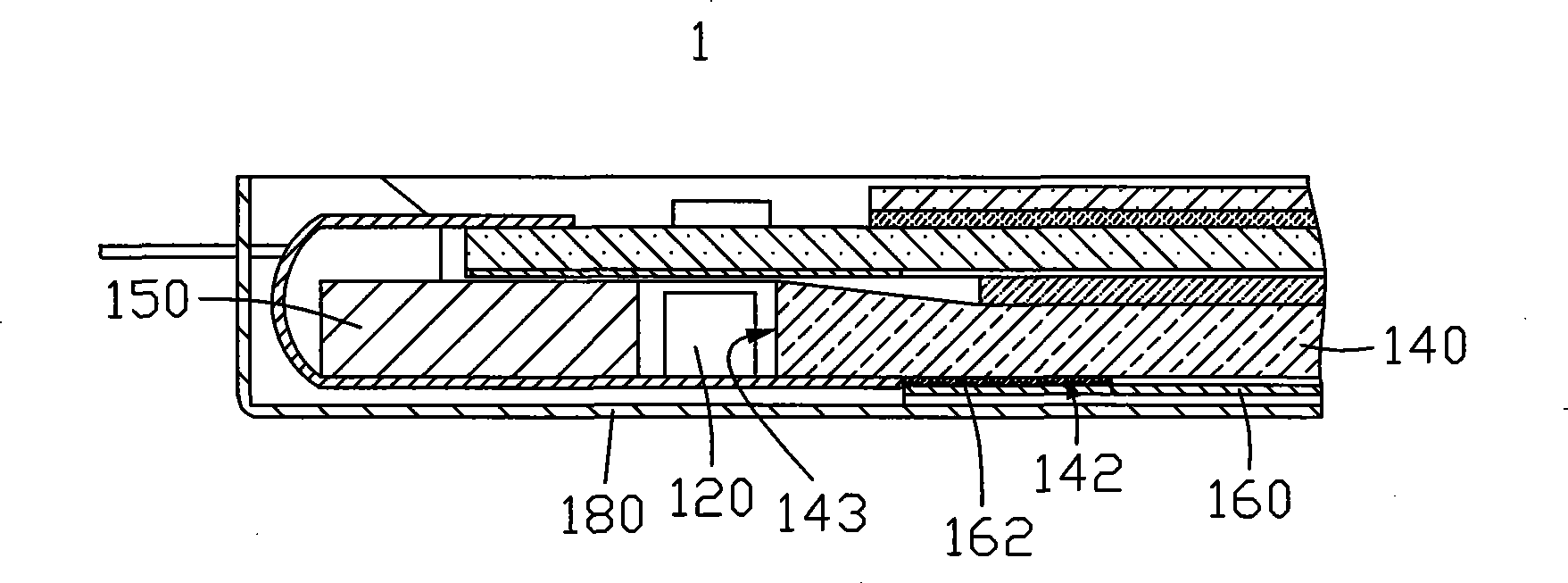

[0025] The backlight module 20 includes a light-shielding tape 210 , a light source 220 , an optical film set 230 , a light guide plate 240 , a plastic frame 250 , a reflector 260 and a metal back plate 280 . The light guide plate 240 includes a light-emitting surface 241, a bottom surface 242 opposite to the light-emitting surface 241, a light-incident surface 243 intersecting the light-emitting surface 241, two opposite side surfaces 244 connected to the light-incident surface 243, and a bottom surface 242 disposed on the light-emitting surface 241. A plurality of protrusions 245 on two opposite sides 244 . The plastic frame 250 includes a plurality of receiving grooves 255 matched with the plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com