Oil head for blade propeller turbine

An oil receiver and water turbine technology, which is applied in the field of oil receivers of rotary sluice turbines, can solve the problems of poor sealing, low sensitivity of mechanical feedback, difficult installation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

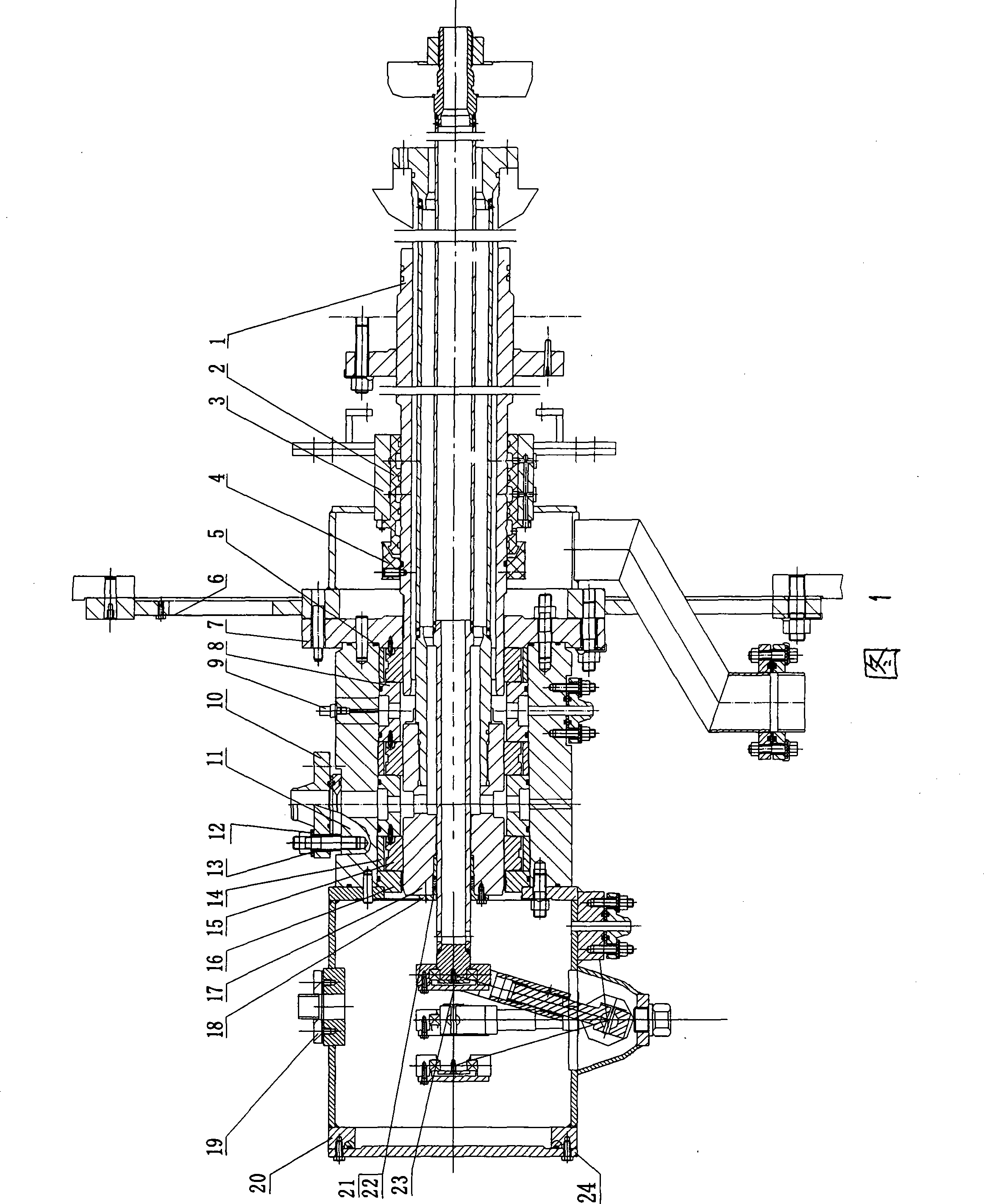

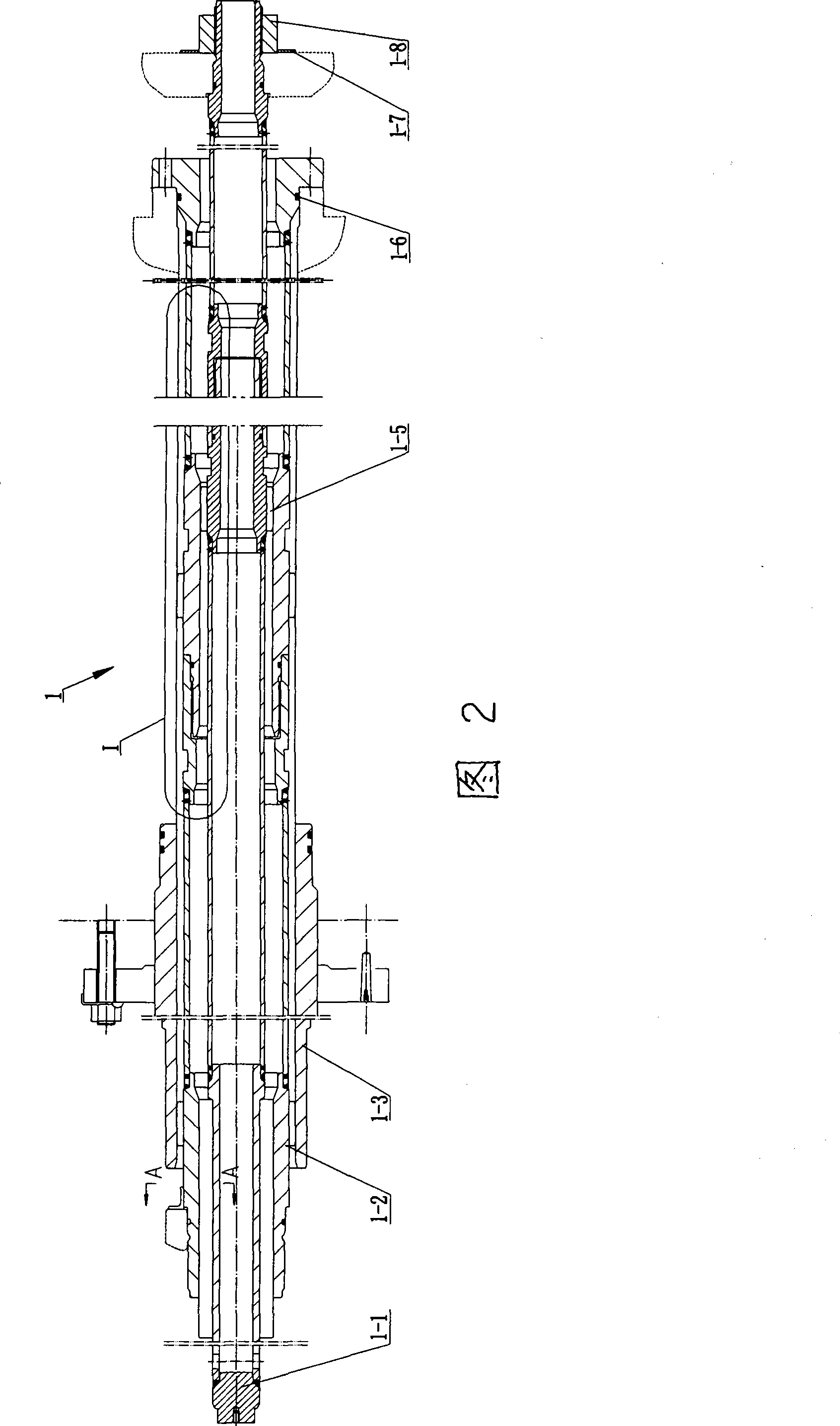

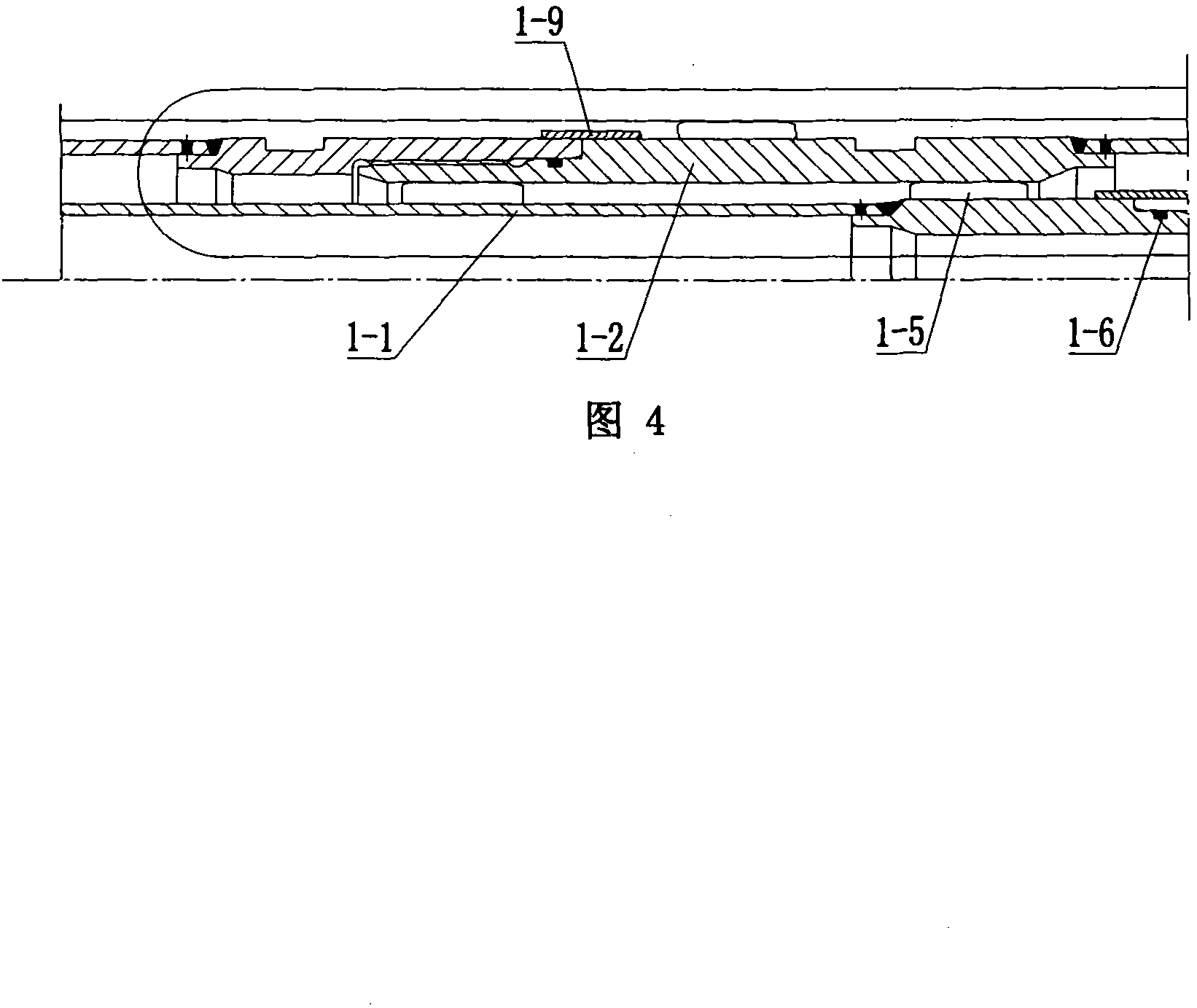

[0017] Please refer to Fig. 1-Fig. 6, the oil receiver of the paddle type turbine mainly includes the operation oil pipe assembly 1, the oil receiver body 11, the front oil tank 20 and the recovery mechanism 23, which consists of the inner pipe 1-1, the middle pipe 1-2 and The operation oil pipe assembly 1 composed of outer pipe 1-3 is connected with the oil receiver body made of seamless steel pipe to form an integral structure, and each section of the pipe body of the operation oil pipe assembly inner pipe, middle pipe and outer pipe is formed by connecting threaded heads. The threaded joints of each section of the pipe body are equipped with limit blocks 1-9 to prevent loosening, and O-rings 1-6 to prevent oil leakage and oil channeling are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com