Technique for preparing consumer waste regenerated coal

A domestic waste and production process technology, applied in the field of domestic waste recycled coal production technology, can solve problems such as urban domestic waste, achieve the effects of reducing emissions, comprehensive components, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

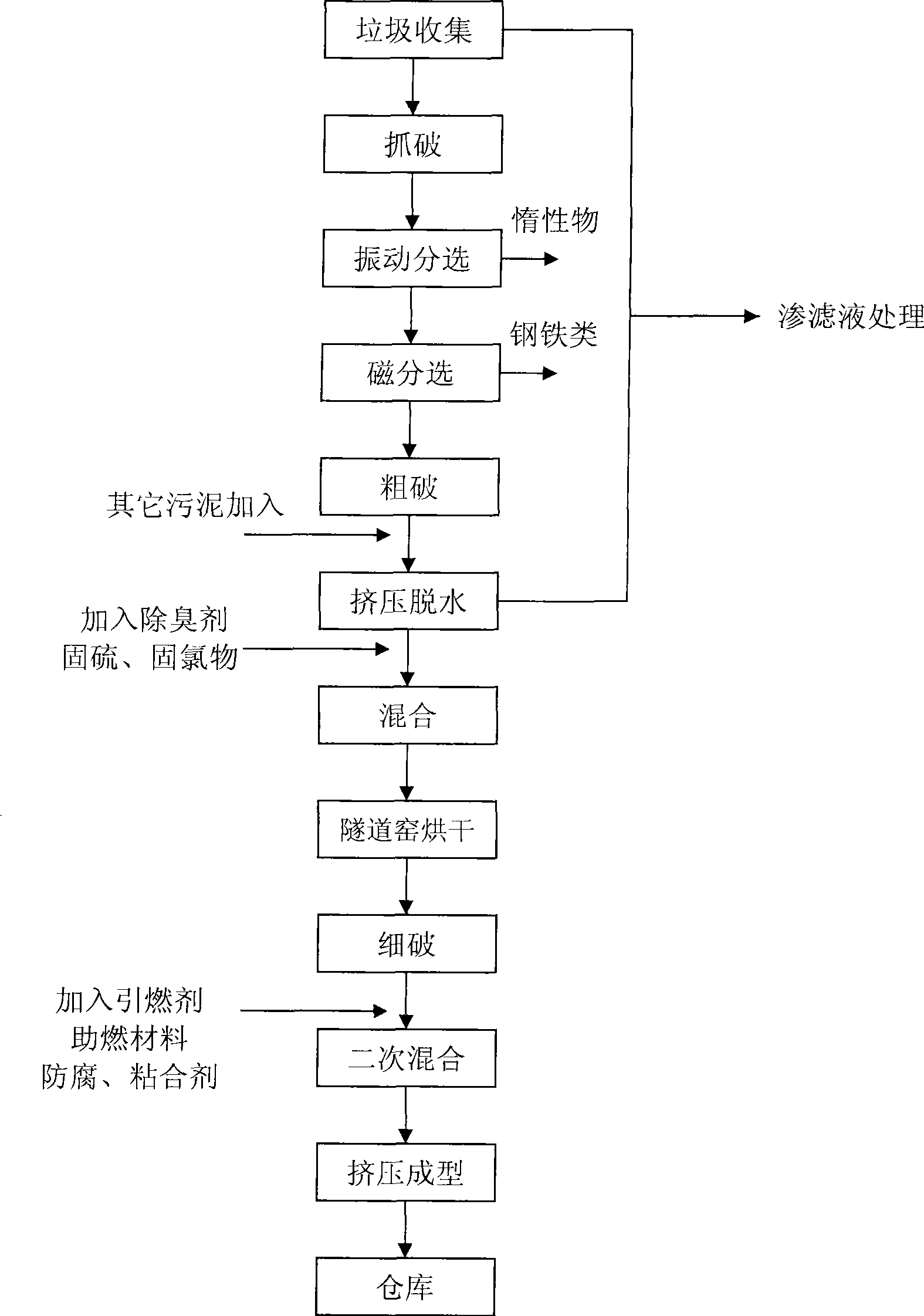

[0036] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0037] The domestic waste recycled coal production process includes the following steps:

[0038] 1. Garbage collection

[0039] The garbage dump truck enters the platform to unload, and is transported to the stacking point through the belt. Enter the storage hopper through the vertical elevator for standby. The lower part of the bucket is equipped with pipes to collect leachate, and an underground collection pool is set up to be pumped into the regulating pool of the sewage treatment station to be treated.

[0040] 2. Scratching and magnetic separation

[0041] Remove coarse and visible inert objects (non-combustible), such as stones, large pieces of glass, and iron metal objects. Use the grabbing machine to break and separate the bagged garbage, and then use the magnetic separator to suck out all the magnetizable metals in the garbage, and then send it to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com