Stacking robot

A palletizing robot and palletizing technology, which is applied in the field of robot manufacturing, can solve the problems of difficult packaging and limited weight of objects that the gripper can bear, and achieve the effect of easy packaging of soft bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

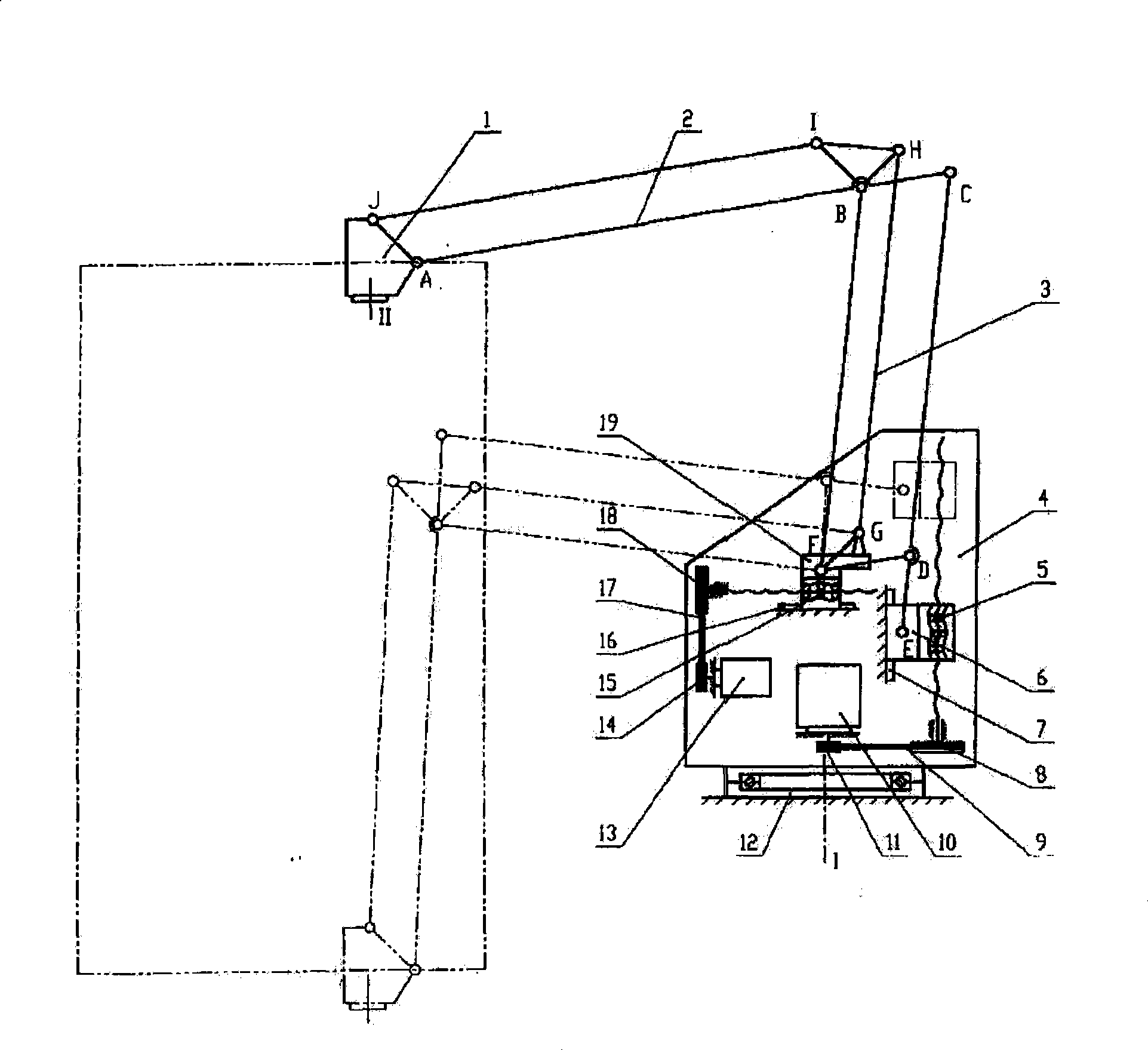

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] The arm and the main mechanism of the palletizing robot of the present invention are prior art, and will not be repeated here. The core of the present invention will be introduced below: it is specially used for grabbing bag packaging, especially the bag gripper structure of bag packaging in the food industry.

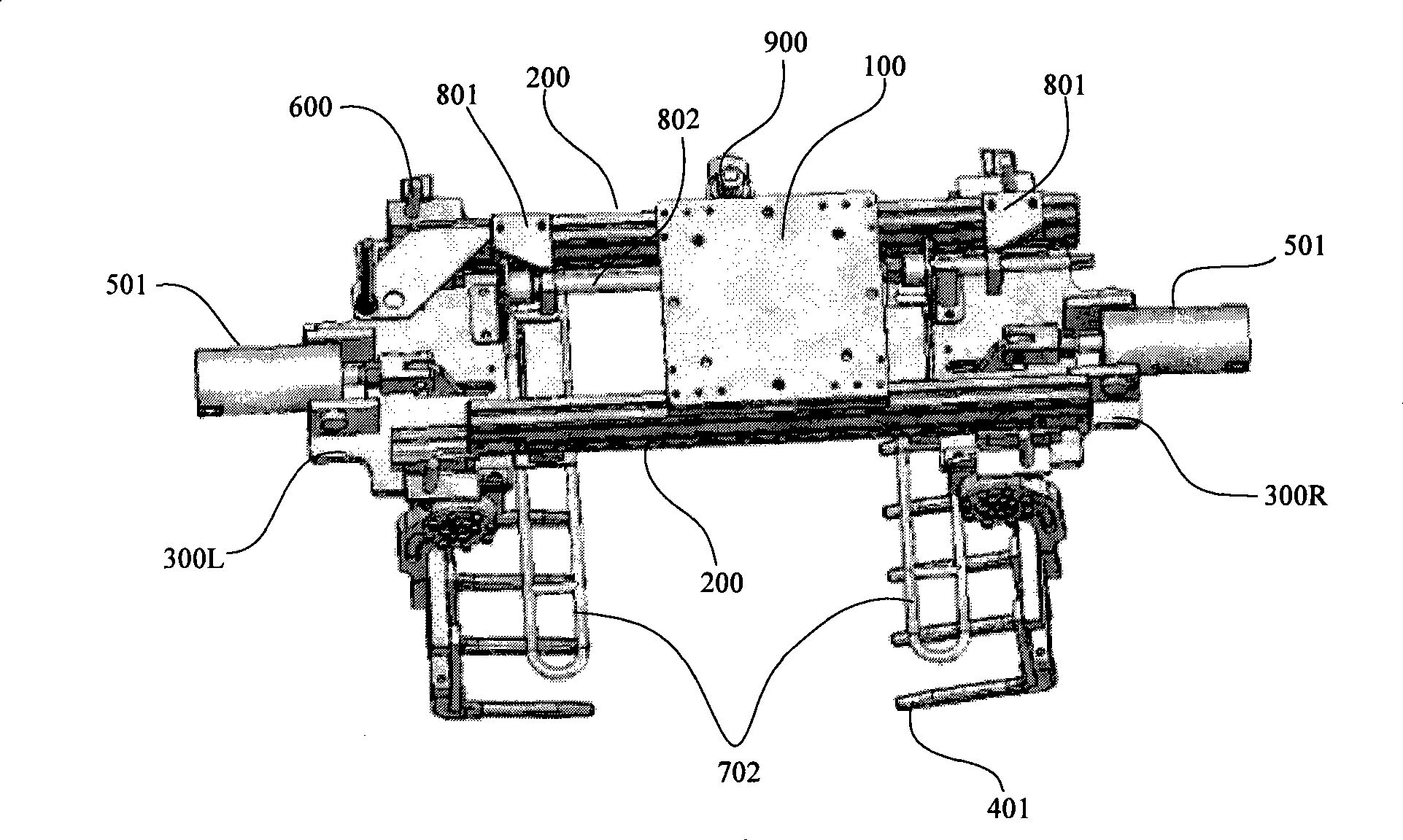

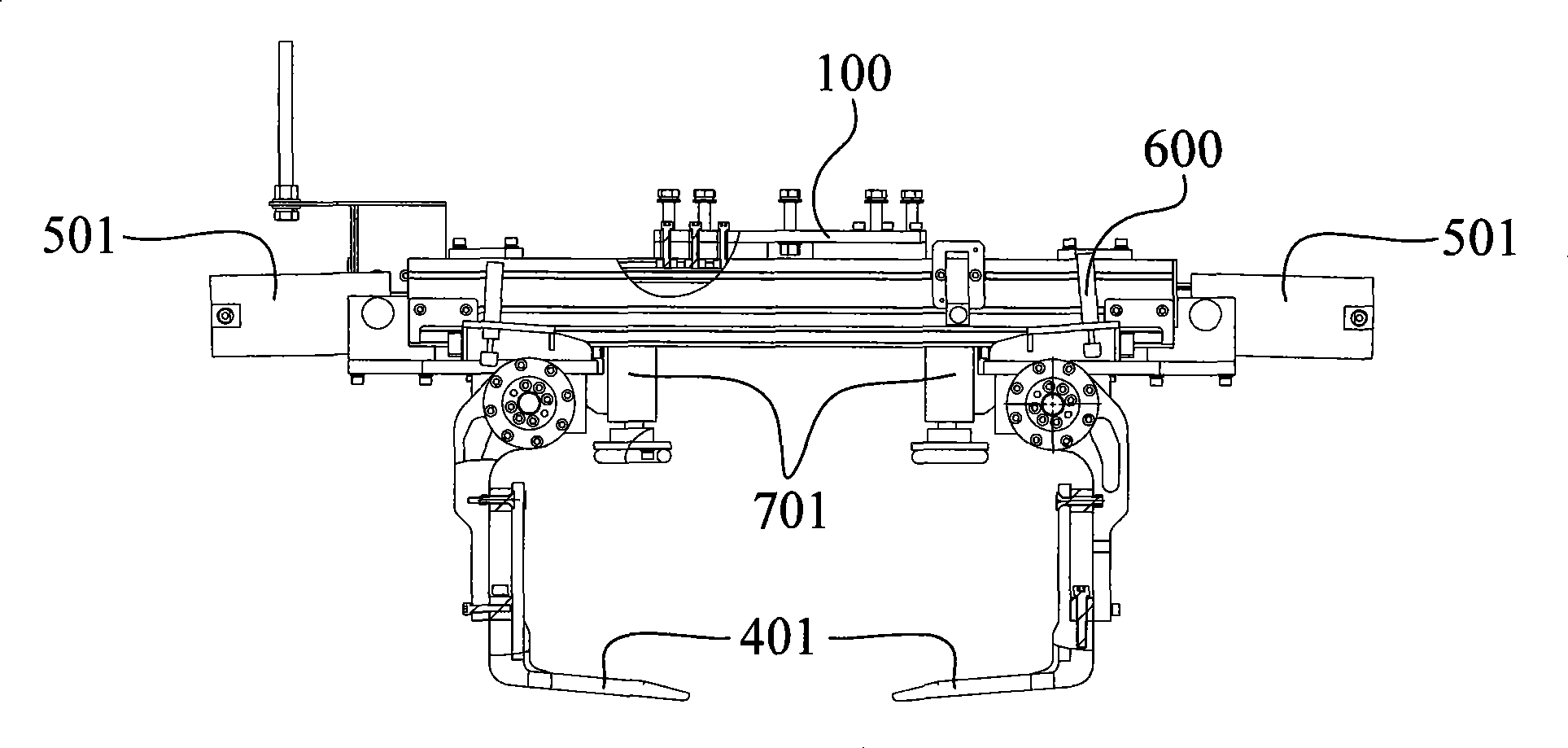

[0023] See figure 2 , which is a three-dimensional view of a bag gripper of a palletizing robot according to an embodiment of the present invention, please refer to Figure 3-Figure 5 , which is a three-view view of a bag gripper of a palletizing robot according to an embodiment of the present invention. The bag gripper of the palletizing robot includes a top plate 100, a parallel guide rail 200, a left support plate 300L, a right support plate 300R, a finger mechanism and a platen pressing mechanism. The top plate 100 is fixedly mounted on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com