Closed type static pressure turntable and bidirectional piston clamping mechanism thereof

A technology of clamping mechanism and hydrostatic turntable, applied in metal processing machinery parts, large fixed members, metal processing equipment, etc. Problems such as poor capacity, to achieve the effect of smooth rotation, small friction coefficient, and increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

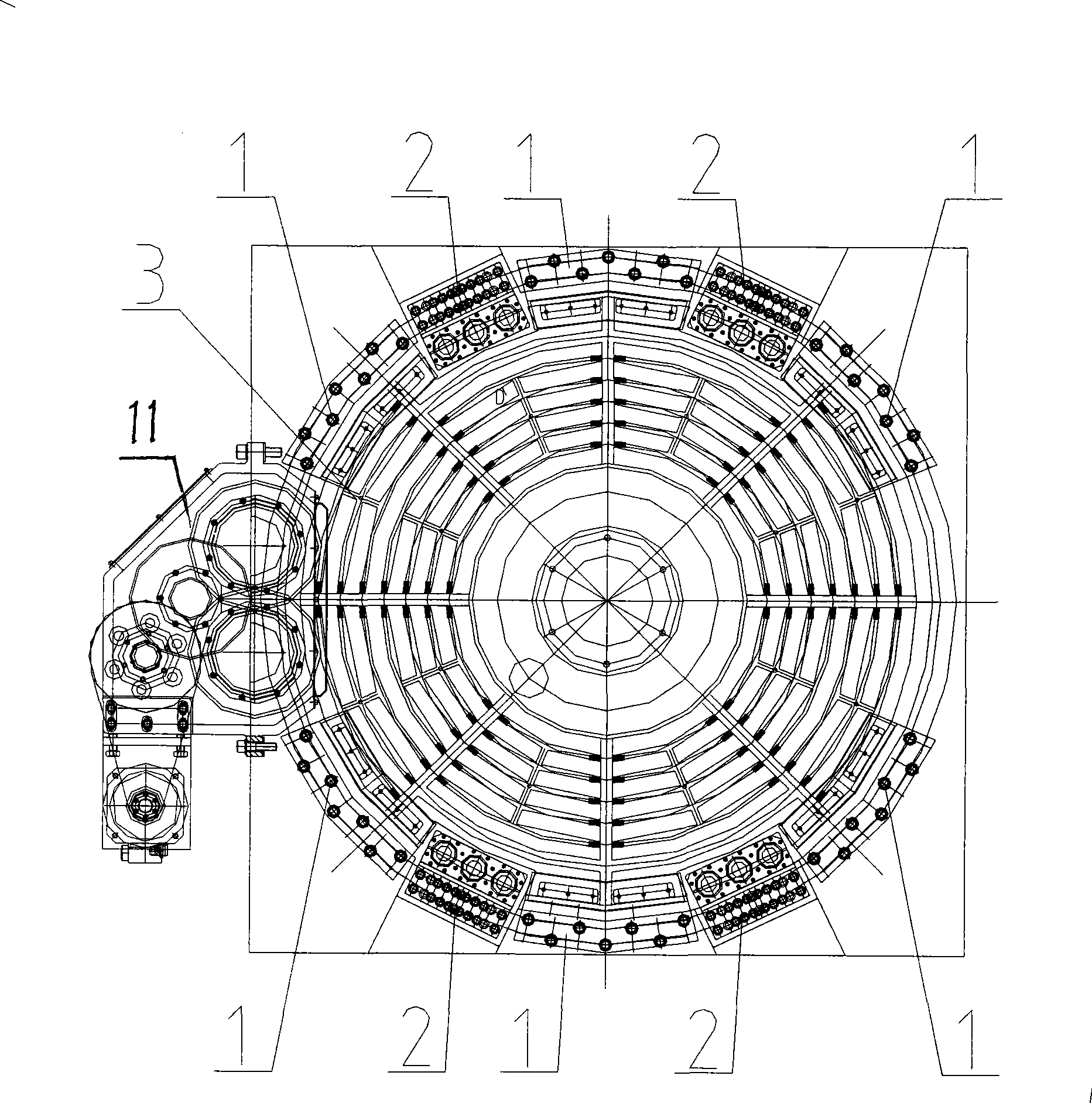

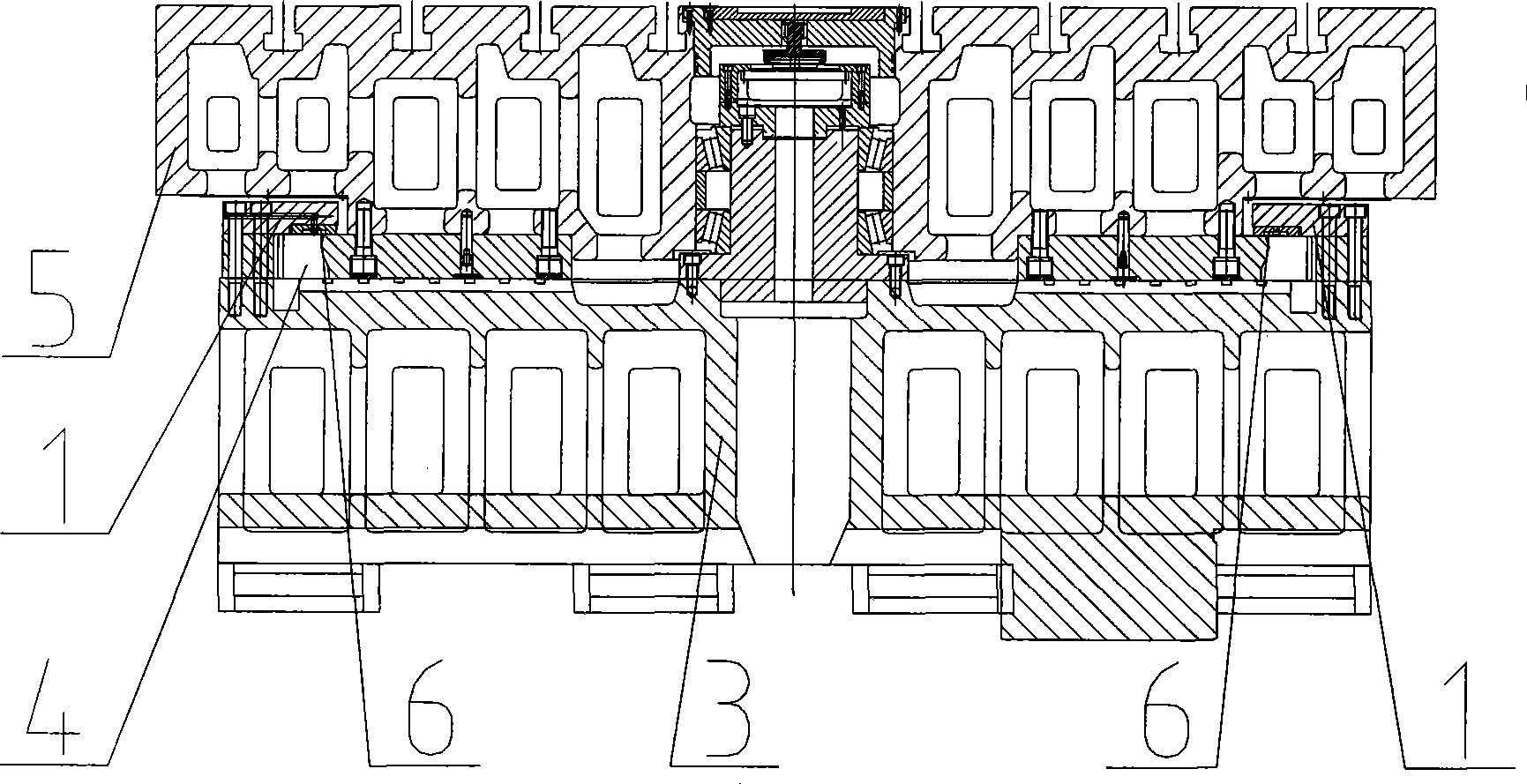

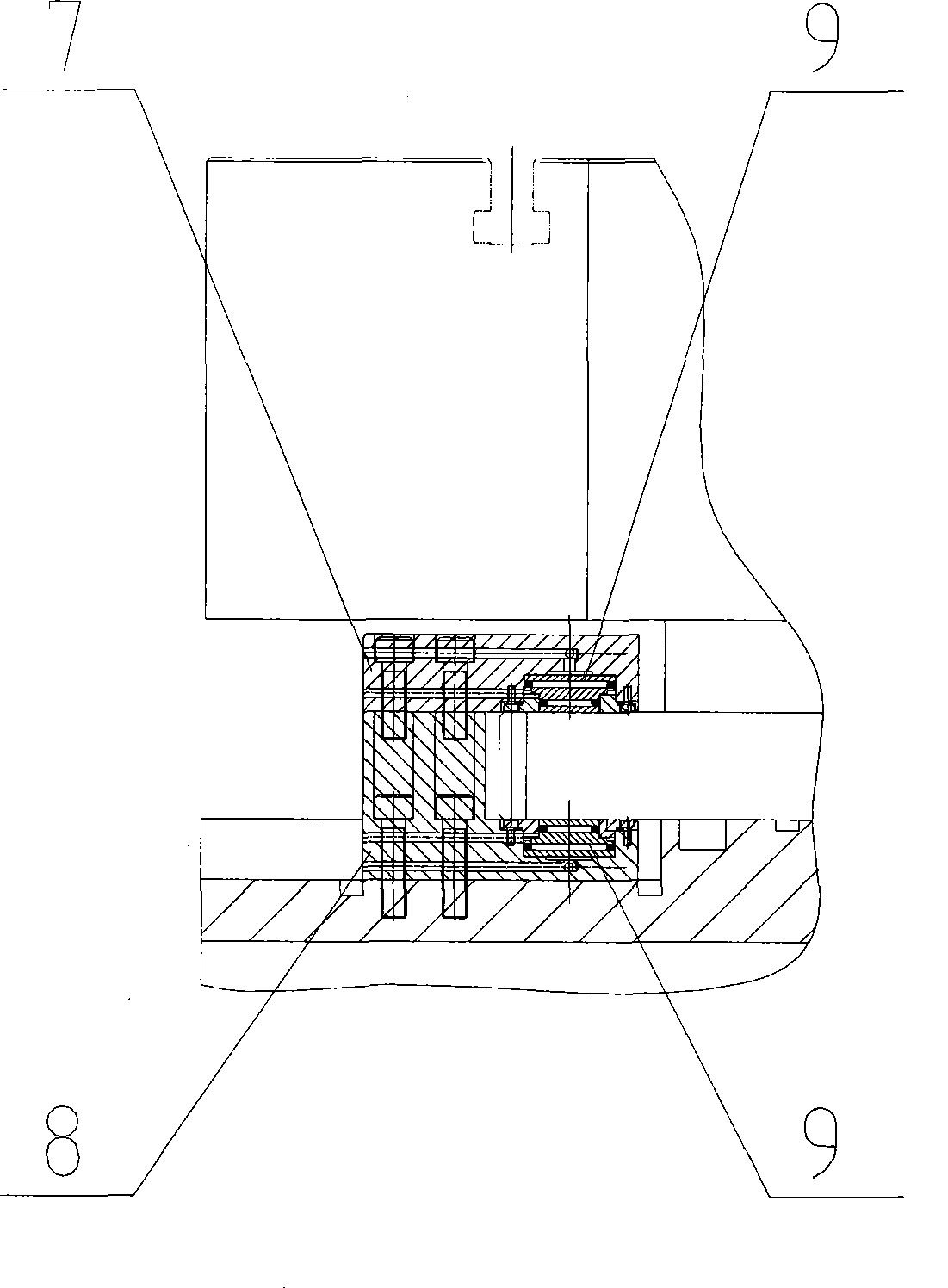

[0014] The closed static pressure turntable and its two-way piston clamping mechanism are equipped on large and medium-sized CNC machine tools, including a multi-head pump supplied by a hydraulic pump station, and a piston drive device. Type static pressure structure, such as figure 2 : The large ring gear 4 is installed on the lower part of the worktable turntable body 5, and the inner hole of the lower cylinder of the worktable turntable body 5 and the large ring gear 4 adopts a coaxial base hole system for clearance fit, and falls on the sliding seat 3 together. 4. In the gap protruding from the turntable body 5 of the worktable, the pressure plate 1 and the clamping mechanism 2 are arranged at intervals, see figure 1 : Evenly distributed within the range of 135° on both sides of the driving device, four clamping mechanisms 2 are arranged between the pressure plates 1 at intervals to form a relatively high flatness and smoothness. The bottom surface of the large ring gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com