Stable isotope zinc-70 separation method

A separation method and stable technology, applied in the field of separation of stable isotope zinc-70, can solve the problems of low separation efficiency, high operation cost, limited quantity of gaseous zinc salt, etc., and achieve simple device, economical operation cost and cheap price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Dissolving benzene-15-crown-5 crown ether solvent with chloroform at normal temperature, preparing 0.2mol / L crown ether solution as the organic liquid film phase;

[0020] 2) Prepare 2.0mol / L ZnCl with a concentration of 0.2mol / L HCl solution 2 solution as the injection phase;

[0021] 3) preparing a concentration of 0.02mol / L HCl solution as the receiving phase;

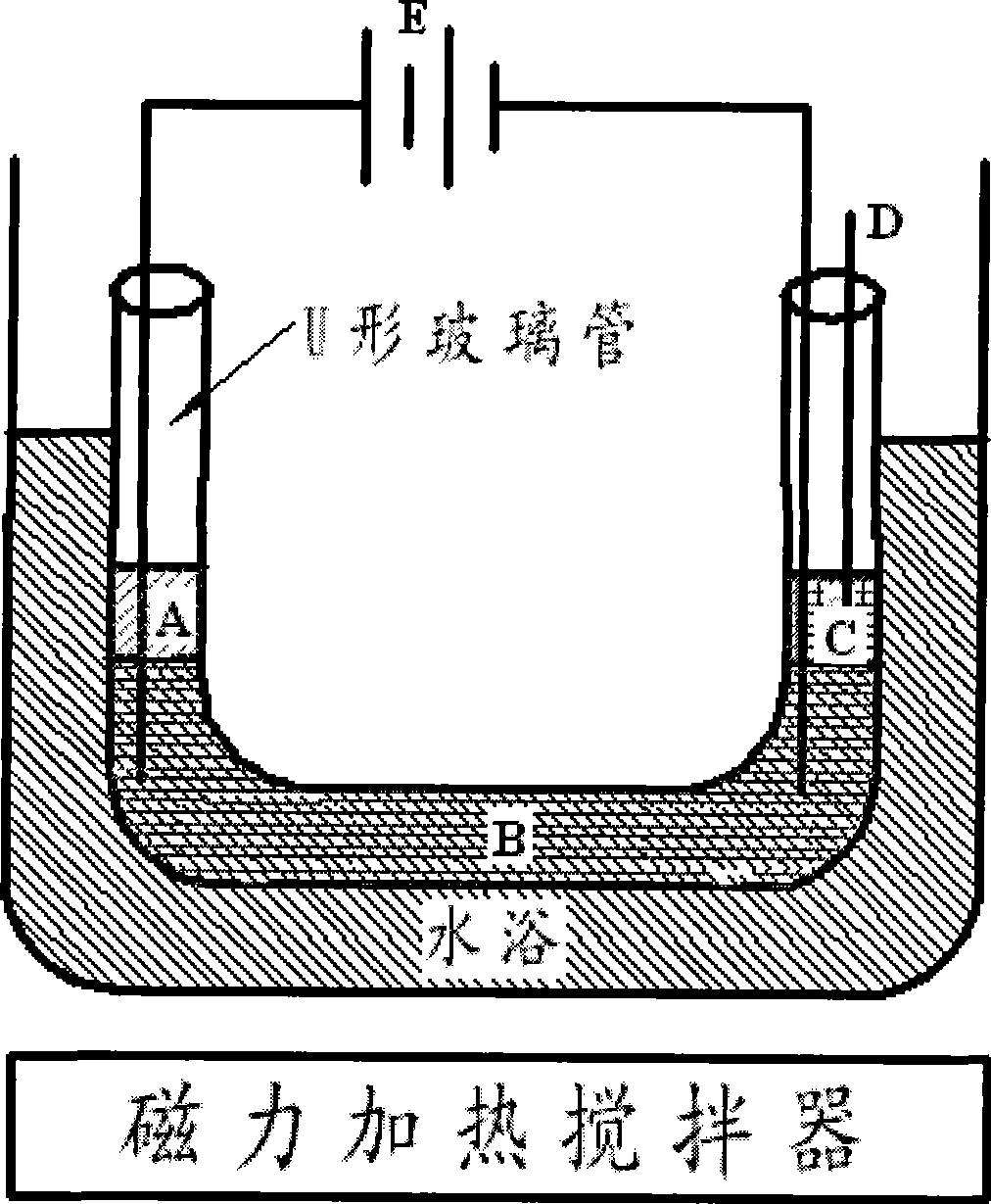

[0022] 4) Put 50ml of organic liquid film phase B in a U-shaped glass tube, add 10ml of injection phase A to one side of the U-shaped glass tube, add 10ml of receiving phase C to the other side, and insert the positive and negative poles of DC power supply E into In the injection phase and receiving phase on both sides of the U-shaped glass tube, put the U-shaped glass tube in a water bath environment and place it on a magnetic heating stirrer, control the temperature of the water bath at 35 ° C, and perform magnetic stirring at a speed of 150 rpm to accelerate the zinc ions in the Extraction and back ex...

Embodiment 2

[0029] 1) Dissolving benzene-15-crown-5 crown ether solvent with chloroform at normal temperature, preparing 0.1mol / L crown ether solution as the organic liquid film phase;

[0030] 2) With a concentration of 0.1mol / L H 2 SO 4 Solution preparation 1.0mol / L ZnSO 4 solution as the injection phase;

[0031] 3) preparing a concentration of 0.06mol / L HCl solution as the receiving phase;

[0032] 4) Put 50ml of organic liquid film phase B in a U-shaped glass tube, add 10ml of injection phase A to one side of the U-shaped glass tube, add 10ml of receiving phase C to the other side, and insert the positive and negative poles of DC power supply E into In the injection phase and receiving phase on both sides of the U-shaped glass tube, put the U-shaped glass tube in a water bath environment and place it on a magnetic heating stirrer, control the temperature of the water bath at 25 ° C, and perform magnetic stirring at a speed of 100 rpm to accelerate the zinc ions in the Extraction ...

Embodiment 3

[0038] 1) Dissolving benzene-15-crown-5 crown ether solvent with chloroform at normal temperature, preparing 0.3mol / L crown ether solution as the organic liquid film phase;

[0039] 2) Use a concentration of 0.4mol / L HNO 3 Solution preparation 1.5mol / L Zn(NO 3 )2 solution as the injection phase;

[0040] 3) preparing a concentration of 0.1mol / L HCl solution as the receiving phase;

[0041] 4) Put 50ml of organic liquid film phase B in a U-shaped glass tube, add 10ml of injection phase A to one side of the U-shaped glass tube, add 10ml of receiving phase C to the other side, and insert the positive and negative poles of DC power supply E into In the injection phase and receiving phase on both sides of the U-shaped glass tube, put the U-shaped glass tube in a water bath environment and place it on a magnetic heating stirrer, control the temperature of the water bath at 30 ° C, and perform magnetic stirring at a speed of 200 rpm to accelerate the zinc ions in Extraction and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com