Method and apparatus for object temperature control

A technology for objects and electrical conductors, applied in the field of object temperature control and devices, can solve the problems of increasing system costs, reducing the overall efficiency of induction heaters, and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

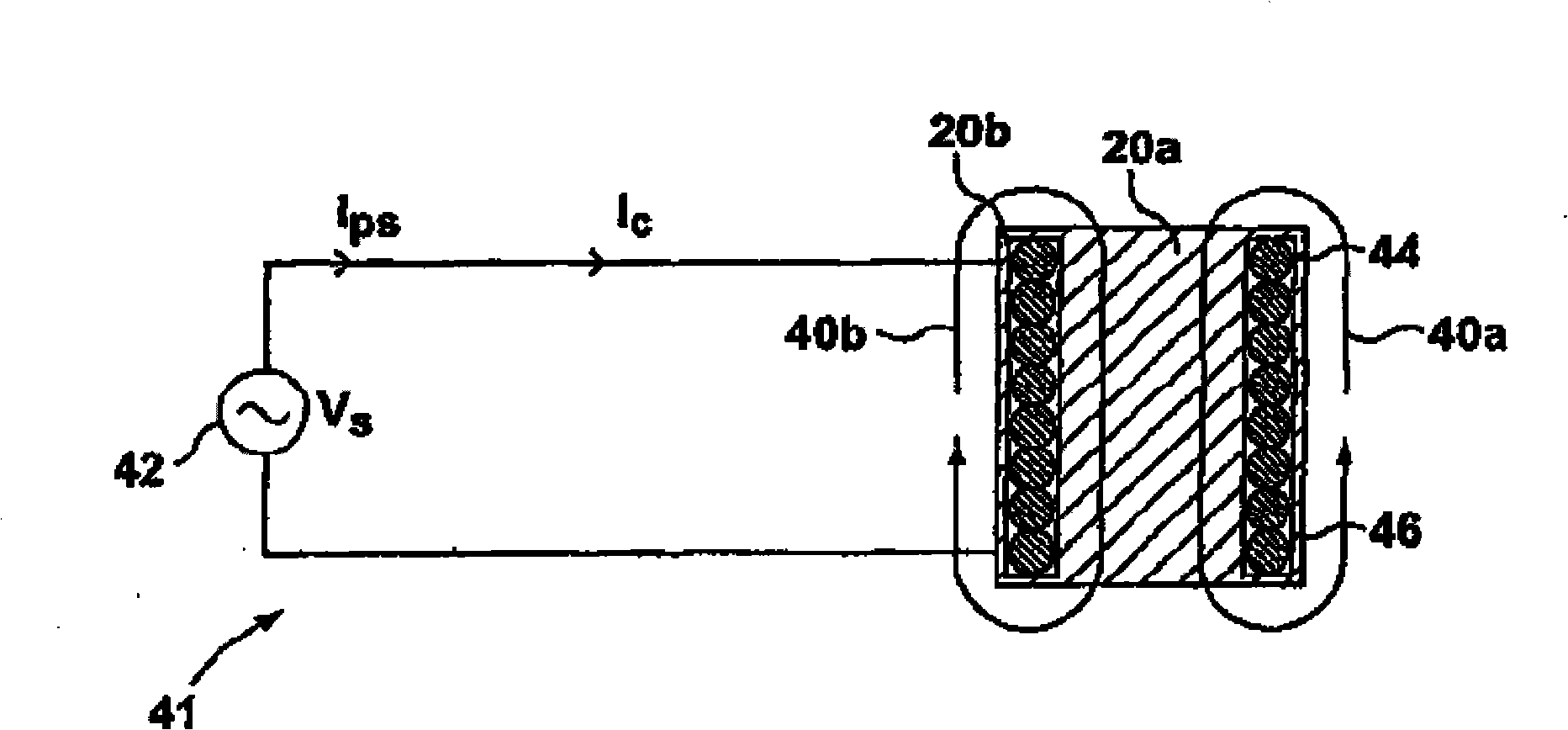

[0051] see image 3 , wherein a simplified schematic diagram of an exemplary embodiment 41 of the present invention is shown generally. A power source 42 supplies an alternating current to a heater coil 44 which is wound around and connected to objects 20a and 20b. In the preferred embodiment, without limitation, coil 44 is disposed within slot 46 formed between 22a and 22b, which forms a closed magnetic structure. When an alternating current is applied to the coil 44, magnetic field lines are generated, as indicated by arrows 40a, 40b. It should be noted that many flux lines are generated around the entire perimeter of the object, only two flux lines 40a, 40b are shown for simplicity. These flux lines generate eddy currents in the objects 20a, 20b, which generate heat according to the skin effect principle described above. In a preferred embodiment, the objects 20a, 20b may preferably be designed so that the maximum flux lines are generated, thereby generating as much heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com