Oblique crankshaft Variable plunger pump

A variable plunger and crankshaft technology, applied in the field of hydraulic power components, can solve the problems of large friction loss, large oil loss and large pressure loss of the main transmission device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This embodiment is used to explain the technical solution of the present invention, and the protection scope of the present invention is not limited to the description of the following structures.

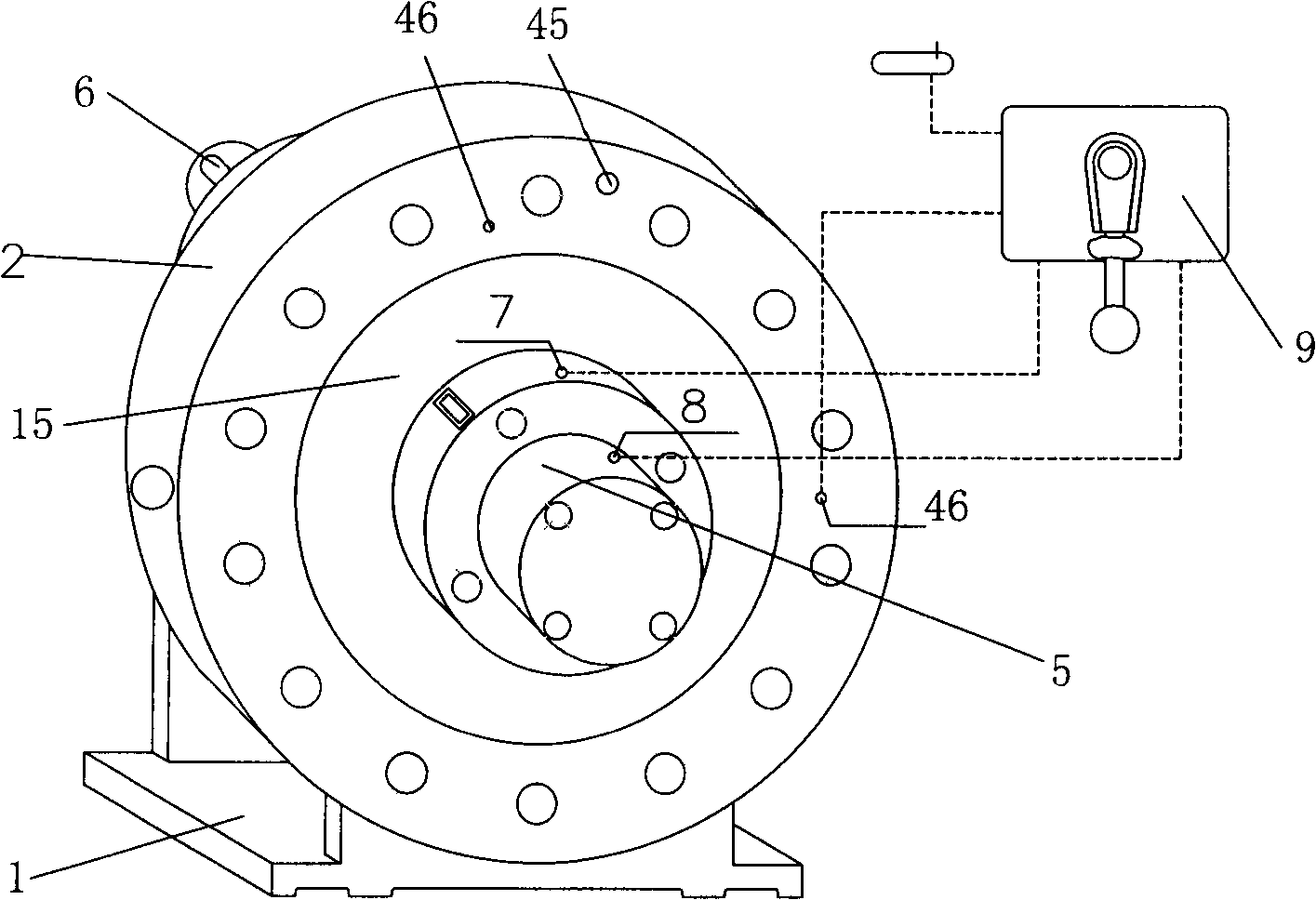

[0017] Such as figure 2 As shown, the shape of the oblique crankshaft variable displacement plunger pump includes a pump body 2 on the base 1, and an oil suction port 3 and an oil pressure port 4 on the pump body 2 for hydraulic oil to enter and exit. The pump body 2 is connected with the pump cover 15 , the variable adjusting device 5 is connected with the pump cover 15 in this embodiment, and the other end of the pump body 2 is connected with the transmission shaft 6 . The oil inlet hole 7 and the oil outlet hole 8 of the variable variable regulating device 5 can be connected with a variable variable control valve 9 .

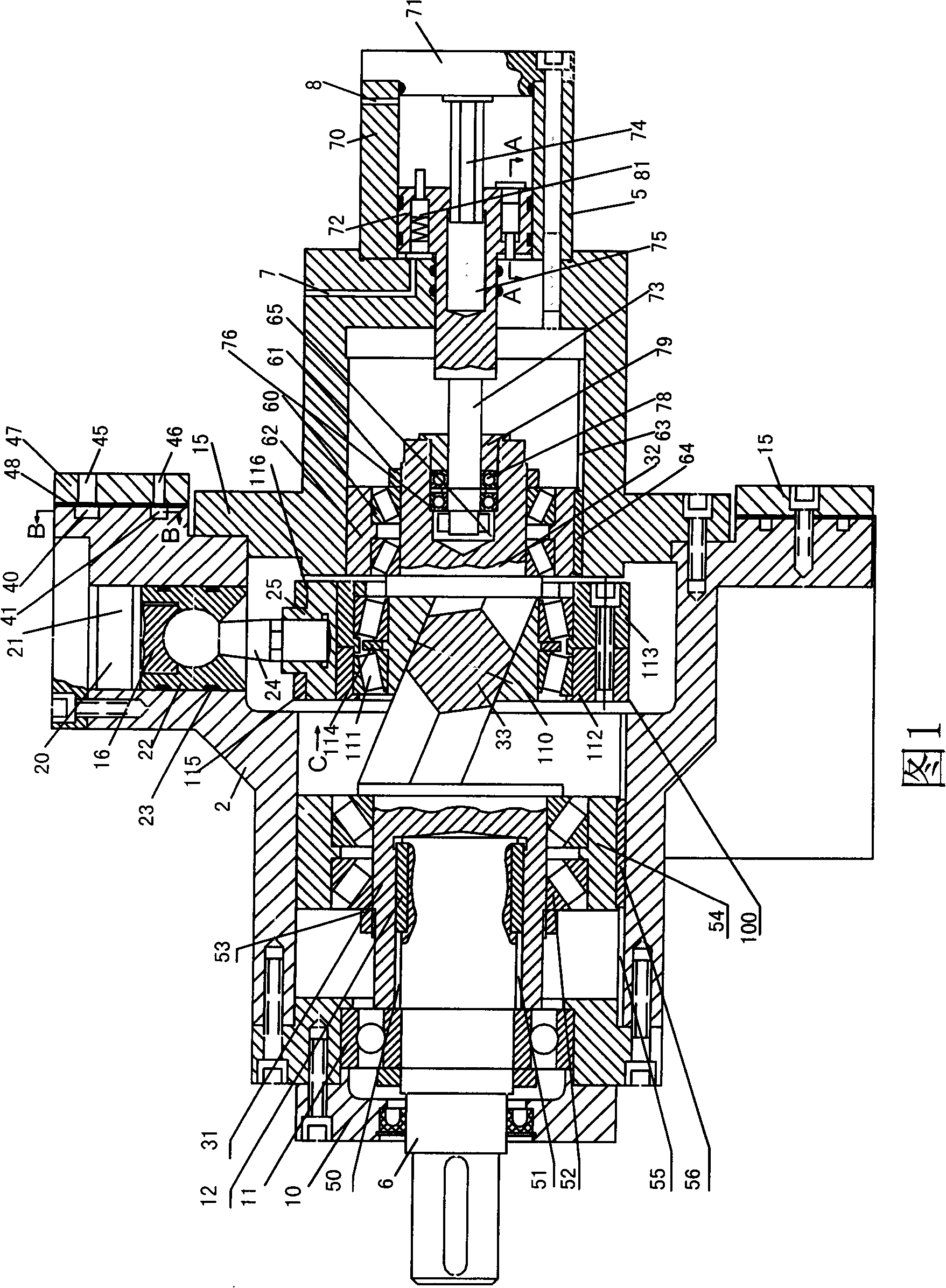

[0018] The internal structure of the inclined crank variable displacement plunger pump is shown in Figure 1. The end face of the pump body 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com