Triplet commutation slurry valve

A slurry valve and three-way technology, which is applied in the field of reversing valves, can solve the problems of increasing investment and energy consumption, increasing installation space, and increasing the number of valves, and achieves compact structure, less space, and shorter opening and closing time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment has the functions of pipeline merging, shortening and channel switching, which can merge and shorten two pipelines, and open and close them alternately according to process requirements.

[0035] In the existing process pipeline, a slurry valve must be installed on each of the two pipelines to alternately open and close (as shown in Figure 7, a slurry valve 55 and a slurry valve 56 are respectively installed on the two pipelines).

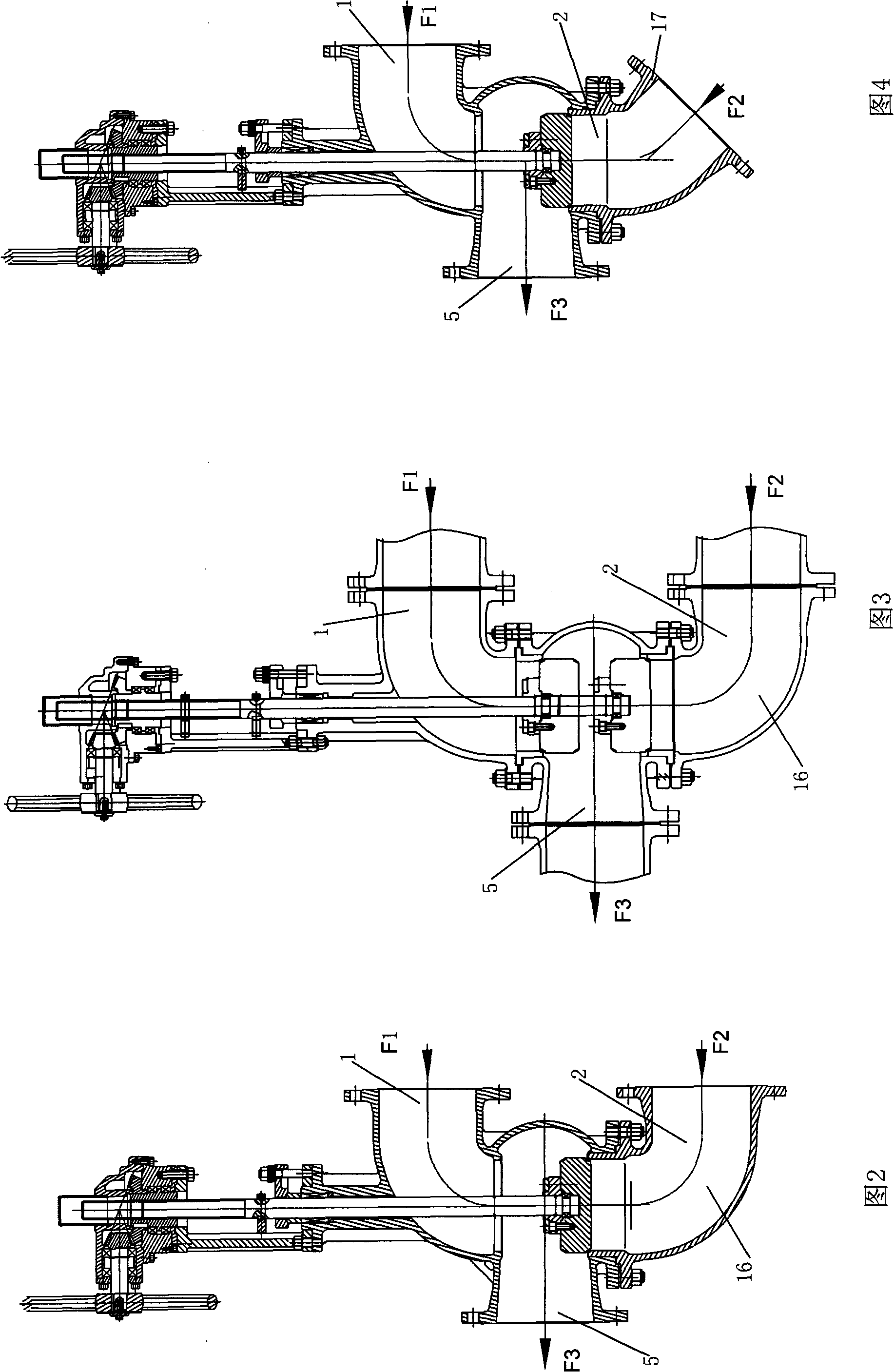

[0036] Adopting the utility model can replace the two pipelines and the two slurry valves to be alternately opened and closed (as shown in FIG. 2 ).

[0037] This embodiment also has multiple usage modes, by figure 1 to Figure 4.

[0038] figure 1 Among them, the axes of the input ends of the two feed pipes (directly connected to the outlets of the two slurry delivery pumps) of the utility model are in a state of being perpendicular to each other.

[0039] Fig. 2 shows that the feed pipe 2 is provided with an extension val...

Embodiment 2

[0044] It is shown by the structure shown in Figure 5; its characteristic is that the axis of the input end of the discharge pipe 5 and the axis of the input end of the feed pipe 1 are arranged obliquely (135 degrees); its application method is determined by Figure 10 show. It has the function of simplifying the pipeline and reversing the opening and closing. It can change the direction of the two pipelines without disassembling the pipeline, and the reversing opening and closing is quick and convenient.

[0045] In the alumina process piping system, the design application has two decomposition tanks for alternate feeding; the conventional method is to share a reversing disassembly elbow ( Figure 9 shown) to connect the two decomposition tanks respectively. The operation of this method is relatively complicated; if the material is changed from the decomposition tank 21 to the decomposition tank 22, it is necessary to start the pneumatic discharge valve 28 on the tank wall t...

Embodiment 3

[0047] Shown by the structure shown in Figure 6, it is characterized in that the axis of the output end of the discharge pipe 5 coincides with the axis of the input end of the feed pipe 2; its application method is determined by Figure 12 show. It has the functions of easy operation, leakage prevention, and parallel reversing opening and closing. It can implement target decomposition tank discharge for multiple decomposition tanks using parallel pipelines according to process needs.

[0048] In the existing alumina process pipeline system, multiple slide valves are commonly used to implement alternate discharge of multiple decomposition tanks in parallel pipelines ( Figure 11 Shown; Such decomposition tanks can have many according to production needs, only draw two among the figure). The mode of operation is: close the gate valve 43 and the gate valve 42; open the gate valve 41 and the gate valve 45, and discharge the decomposition tank 21 (the slurry flows to S). Close th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com