Negative pressure water seal tank

A water-sealed tank and negative pressure technology, applied in sealing, closing, packaging, etc., can solve problems such as high project investment and increased construction difficulty, and achieve the effects of simplifying process piping, reducing construction difficulty, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] 【Example】

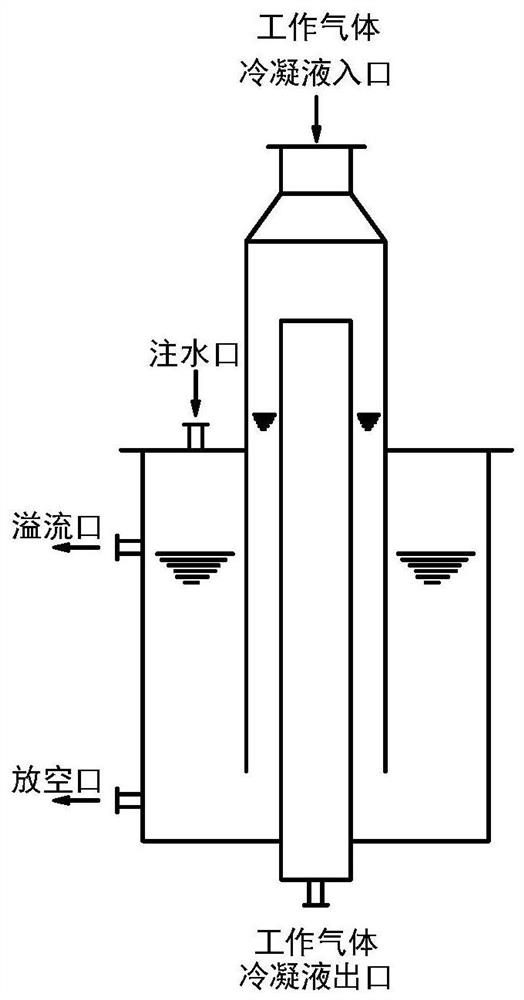

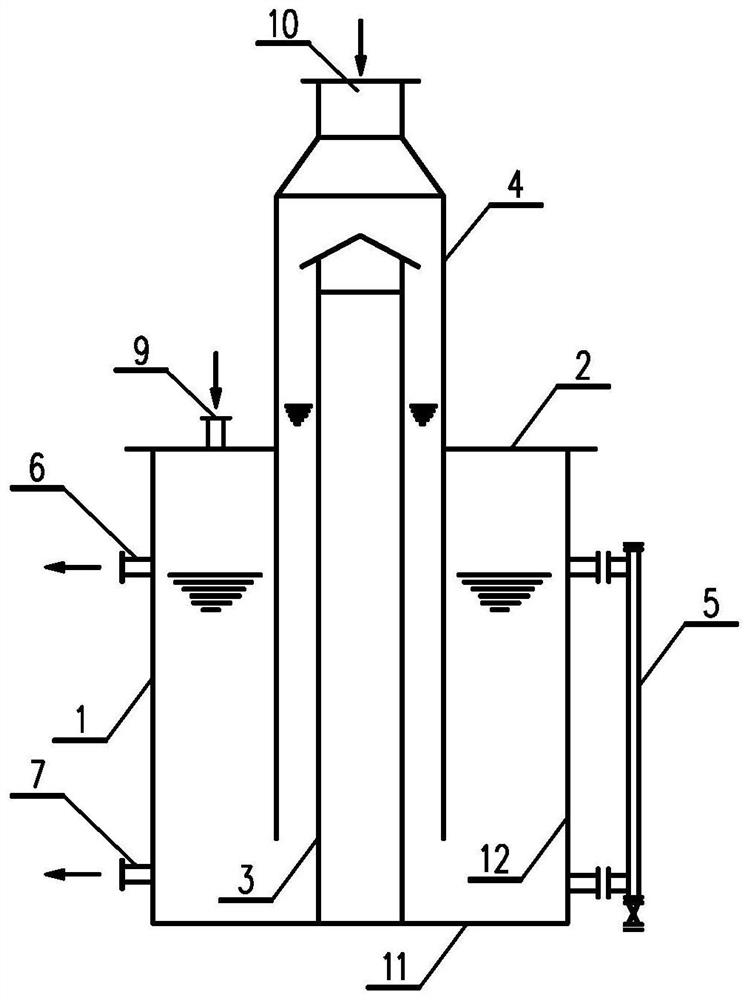

[0025] Such as image 3 As shown, a negative pressure water seal tank includes a tank body 1 , a cover plate 2 , an inner cylinder 3 , an outer cylinder 4 and a liquid level gauge 5 .

[0026] The tank body 1 includes a bottom plate 11 and a side wall 12 fixedly connected to the bottom plate 11 , the upper part of the side wall 12 is provided with an overflow port 6 , and the lower part is provided with a vent port 7 . The overflow port 6 is also the gas condensate outlet at the same time, the overflow port and the gas condensate outlet are integrated, and the working gas condensate flows out from the overflow port 6 . The liquid level gauge 5 is fixed on the side wall 12 of the tank body 1 .

[0027] Such as image 3 , Figure 5 As shown, the inner cylinder 3 is fixedly connected to the upper surface of the bottom plate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com