Development of print plates in offset printers

A printing machine and printing mechanism technology, applied in the direction of lithographic rotary printing machine, printing machine, rotary printing machine, etc., can solve the problem of not being able to see the solution, and achieve the effect of reliable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

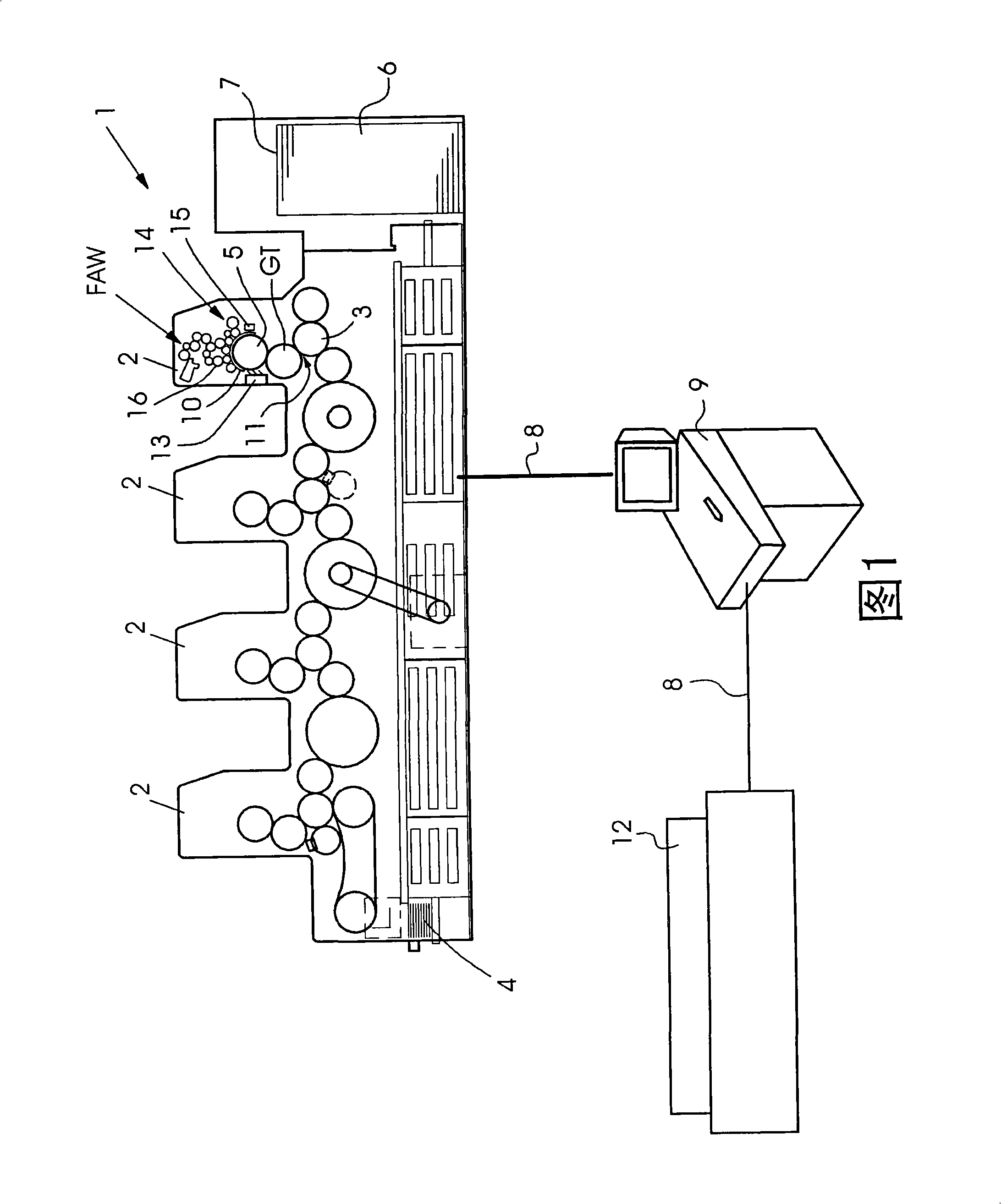

[0027] FIG. 1 depicts a sheet-fed offset printing press 1 with four printing units 2 . Each of the four printing units 2 is provided with an inking unit FAW and a dampening unit 14 . During the printing operation, printing ink is applied to the plate cylinder 5 in the printing unit 2 by the inking unit FAW via the ink roller 16 . In order to be able to influence the consistency of the printing ink in the inking unit FAW, each printing unit 2 also has a dampening unit 14 . The dampening unit 14 delivers dampening agent to the inking unit FAW so that the consistency of the ink can be changed thereby. The inking unit FAW and the dampening unit 14 can be pressed separately onto the plate cylinder 5, the dampening unit 14 and the inking unit FAW can also be pressed away from each other. The printing form cylinder carries a printing form 10 which contains the color separations for the corresponding printing unit 2 . The color separations on the printing plates 10 of the printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com